2025 Guide: How to Choose the Best Milling Machine Tools for Your Workshop

In the rapidly evolving landscape of manufacturing, the selection of milling machine tools is pivotal for achieving precision and efficiency in a workshop environment. According to a recent industry report by MarketsandMarkets, the global milling machine tools market is projected to reach USD 12 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.1%. This growth is largely driven by the increasing demand for high-performance machining solutions in sectors such as aerospace, automotive, and consumer goods manufacturing.

As workshops strive to enhance their operational capabilities, understanding the various features and specifications of milling machine tools becomes essential. The right milling tools not only improve productivity but also ensure the consistent quality of machined components. Factors such as material compatibility, tool lifespan, and operational flexibility should be critically assessed during the selection process. Furthermore, advancements in digital technologies, including CNC (Computer Numerical Control) and automation, have significantly influenced milling tool design, making it crucial for workshop owners to stay abreast of these developments.

By strategically focusing on the selection criteria for milling machine tools, workshop owners can not only maximize their investment but also adapt to the shifting demands of the market. This guide aims to provide comprehensive insights into the critical considerations for choosing the best milling machine tools, helping professionals make informed decisions that align with their specific operational goals.

How to Assess Your Workshop Needs for Milling Machine Tools

When selecting milling machine tools for your workshop, the first step is to thoroughly assess your workshop needs. Begin by considering the types of projects you plan to undertake. Are you focused on small-scale projects, or do you anticipate working on larger components? The scale and complexity of your work will significantly influence the size and capabilities of the milling machine you require. Additionally, evaluate your material preferences, as different machines are designed for specific substances, such as wood, metal, or plastic.

Once you have a clear understanding of your project requirements, consider the space available in your workshop. Milling machines vary in size, and it's crucial to select a tool that fits comfortably within your workspace while still allowing for necessary movement and safety protocols. Consider the layout of your workshop to ensure that you have adequate counter space and access to power sources for your milling equipment. Lastly, don’t overlook your skill level; choose tools that match your expertise while still offering room for growth as you become more experienced in your craft.

Key Features to Look For in Milling Machines and Tools

When choosing milling machines and tools for your workshop, it is essential to pay attention to several key features that can significantly influence your machining projects. One of the primary aspects to consider is the machine's rigidity and stability. A robust build quality ensures minimal vibration during operation, leading to more accurate and consistent milling results. Additionally, look for machines with adjustable speed settings, as varying speeds can optimize the performance of different materials, allowing for greater versatility in your workshop.

Another crucial feature is the tool holder compatibility. Ensure the milling machine can accommodate a range of tool holders, enhancing your ability to switch between different milling operations seamlessly. Furthermore, consider the machine's ease of use, focusing on features like digital readouts and automated feeds, which can improve efficiency and reduce the learning curve for new operators. Finally, assess the availability of support and replacement parts for the milling tools, as this can extend the lifespan of your investment and maintain high productivity in your workshop.

Milling Machine Tool Features Comparison

This chart compares key features of three different milling machines, including power, spindle speed, table size, weight, and price. Use this information to determine which milling machine best suits your workshop needs.

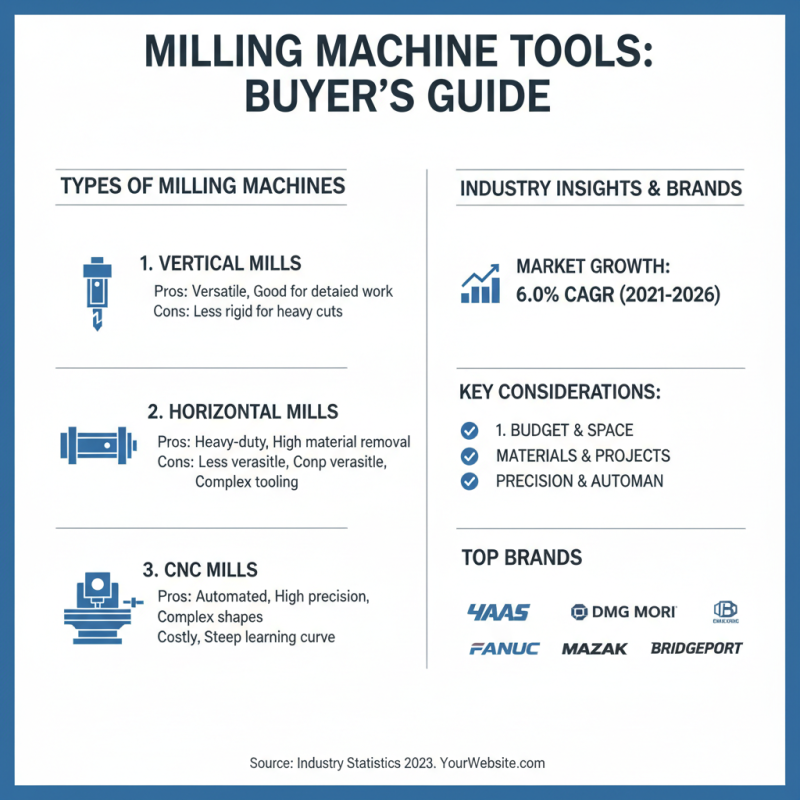

Comparative Analysis of Popular Milling Machine Types and Brands

When selecting milling machine tools for your workshop, a comparative analysis of the various types and brands is essential to make an informed decision. According to the latest industry statistics, the global milling machine market is anticipated to witness a CAGR of approximately 6.0% from 2021 to 2026. This indicates a growing investment in milling technology, reflecting the importance of efficiency and precision in manufacturing processes.

Among the types of milling machines, vertical and horizontal models dominate the market, each serving distinct applications. Vertical milling machines are widely used for their versatility and ease of operation, making them suitable for small to medium-sized workshops. Conversely, horizontal milling machines are preferred for heavy-duty operations due to their capability to handle larger workpieces with greater stability. Recent reports suggest that vertical milling machines account for about 65% of total sales in this segment, highlighting their popularity in various industrial settings.

When it comes to brands, factors such as build quality, precision, and customer support are crucial for long-term satisfaction. A survey conducted by a leading manufacturing research organization indicated that over 70% of operators prioritize precision and durability in their milling machine selection. Furthermore, maintenance costs are another significant consideration; reports have shown that well-maintained machines can operate efficiently for over two decades. As such, understanding the nuances of each type and brand can profoundly impact operational efficiency in your workshop.

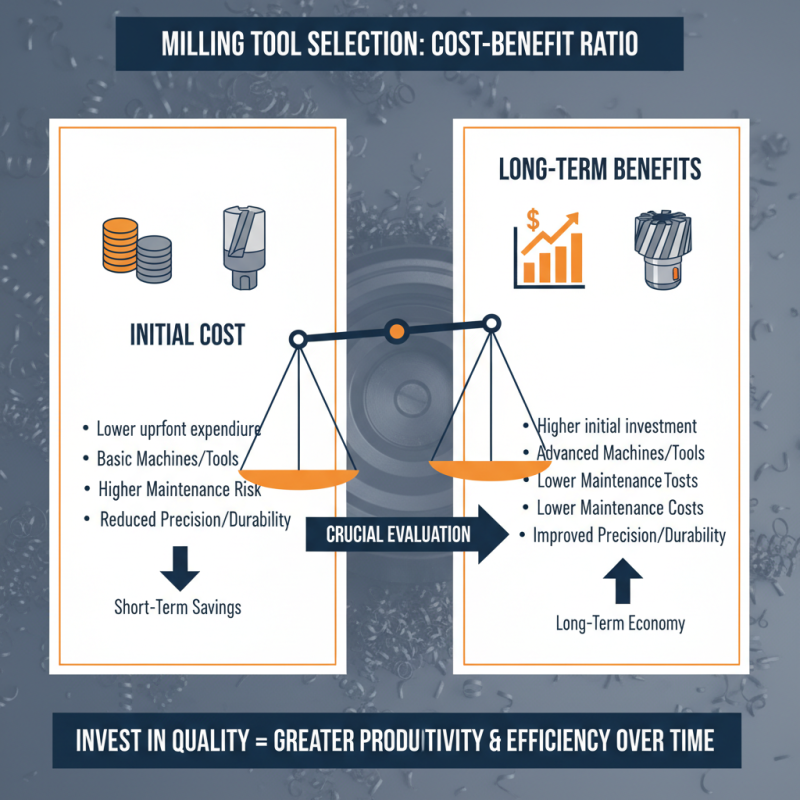

Understanding the Cost-Benefit of Different Milling Tool Options

When choosing milling tool options for your workshop, understanding the cost-benefit ratio is crucial. Different milling machines and tools come with varying price tags and features, which can significantly impact your overall productivity and efficiency. It's essential to evaluate not only the initial cost of the tools but also their long-term benefits, such as durability, precision, and ease of maintenance. Investing in high-quality tools may require a larger upfront expenditure, but the lower maintenance costs and improved results can make them more economical over time.

**Tips:** Before making a purchase, consider the type of projects you will undertake. If your work demands high precision and a smooth finish, prioritize tools that excel in these areas, even if they are more expensive. Additionally, always read reviews and seek recommendations to gauge the effectiveness of a milling tool within different applications.

Another critical aspect of assessing milling tool options is understanding their versatility. Some tools are designed for specific tasks, while others can handle a wider range of applications. Investing in versatile tools can provide significant savings in the long run, as they eliminate the need for multiple specialized machines. Focus on selecting tools that offer flexibility and can adapt to your workshop's evolving needs.

Maintenance Tips for Long-Lasting Milling Machine Performance

Proper maintenance of milling machine tools is essential for ensuring long-lasting performance and reliability in any workshop. According to a report by the National Tooling and Manufacturing Association (NTMA), regular maintenance can extend the lifecycle of machining tools by up to 30%. One key aspect of this maintenance involves a consistent cleaning regimen to remove debris and coolant residues that can accumulate and impact machine precision. Operators should utilize appropriate cleaning agents that will not harm the machine's components, ensuring that each part continues to function optimally.

Additionally, regular inspections of critical components like bearings, spindles, and belts can prevent unexpected breakdowns and costly repairs. The American National Standards Institute (ANSI) stresses that monitoring the wear of these components can significantly enhance machine uptime and productivity. Implementing a routine lubrication schedule, as advised by machinery experts, not only reduces friction but also mitigates wear, thus maintaining the machine's efficiency. Following these maintenance tips can facilitate a smoother operation and longer tool life, ultimately contributing to greater productivity in your workshop.

2025 Guide: How to Choose the Best Milling Machine Tools for Your Workshop - Maintenance Tips for Long-Lasting Milling Machine Performance

| Tool Type | Material | Cutting Speed (RPM) | Maintenance Frequency | Lifespan (Hours) |

|---|---|---|---|---|

| End Mill | High-Speed Steel (HSS) | 6000 | Weekly | 50 |

| Face Mill | Carbide | 8000 | Monthly | 100 |

| Slot Drill | Solid Carbide | 5000 | Every 15 Days | 200 |

| Reamer | Cobalt | 4000 | Bi-Weekly | 80 |

| Taps | Steel | 3000 | Every Use | 40 |

Related Posts

-

Unlocking Innovation: The Vital Role of Machined Parts in Modern Manufacturing Advances

-

Top 5 Advantages of Using Prototype Machined Parts for Efficient Production

-

2025 Top 5 Essential Lathe Machine Parts You Need for Optimal Performance

-

2025 How to Choose the Best CNC Turning Center for Your Machining Needs

-

2025 How to Choose the Best CNC Turning Center for Your Manufacturing Needs

-

How to Choose the Right CNC Turning Center for Your Machining Needs