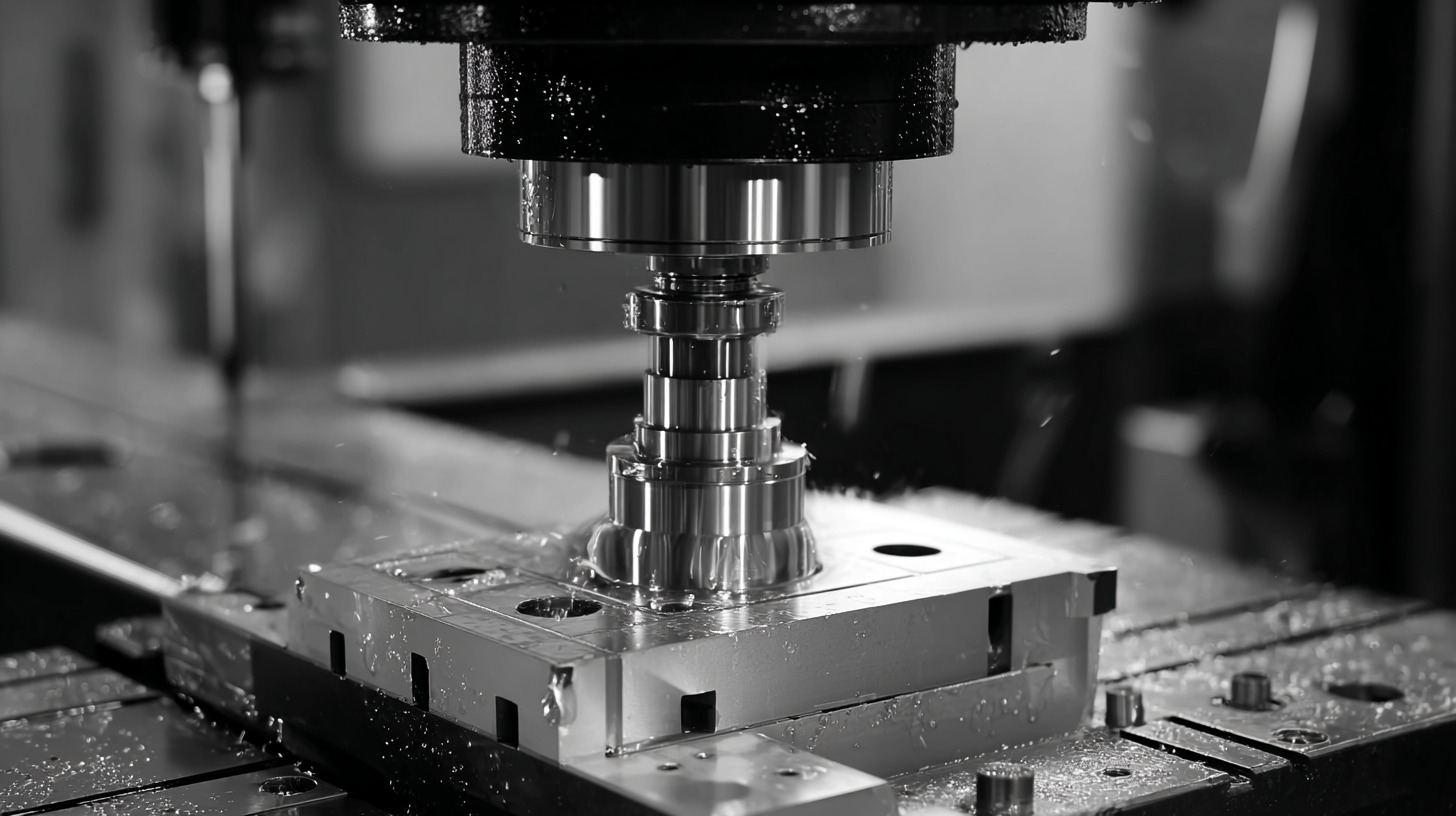

2025 Top 10 CNC Machines: Unveiling the Future of Precision Engineering and Automation

As we stride into 2025, the landscape of precision engineering and automation is being dramatically reshaped by advancements in CNC machines. The global CNC machine market is projected to reach a staggering USD 117 billion by 2028, with a compound annual growth rate (CAGR) of 6.5% from 2021 to 2028, according to a recent industry report. This exponential growth underscores the accelerating trend toward automation in manufacturing, highlighting the essential role that CNC machines play in enhancing productivity and precision across various sectors.

The latest innovations in CNC technology promise to unlock unprecedented levels of efficiency and customization, paving the way for smarter manufacturing processes. Enhanced features such as AI integration, real-time data analytics, and connectivity through the Industrial Internet of Things (IIoT) are setting new benchmarks for operational excellence. As companies increasingly adopt these advanced CNC machines, they not only streamline their operations but also significantly reduce waste and lead times.

This article delves into the top 10 CNC machines that are poised to define the future of the industry in 2025. By examining their cutting-edge capabilities and contributions to precision engineering, we aim to provide insight into the technologies that will shape the next era of manufacturing excellence.

The Evolution of CNC Machines: Trends Shaping the Future of Precision Engineering

The landscape of precision engineering is rapidly transforming with the evolution of CNC machines, driven by advancements in automation and technology. The global CNC machine market is projected to exhibit significant growth, expanding from $101.22 billion in 2025 to $195.59 billion by 2032, reflecting a compound annual growth rate (CAGR) of 9.9%. This surge is attributed to increasing demand for high-efficiency manufacturing processes and the integration of smart technologies that enhance operational capabilities.

In parallel, the tool holders market is also on an upward trajectory, with expectations to rise from USD 1.4 billion in 2025 to USD 2,268.1 billion by 2035, representing a CAGR of 5.2%. This growth underlines the necessity for precision tool management in modern CNC applications, highlighting the importance of innovative tool holder solutions that contribute to the overall effectiveness of CNC operations. As these trends continue to shape the future of precision engineering, the industry is poised to embrace more intelligent and automated systems that will redefine productivity and precision in manufacturing.

Key Technologies Driving CNC Machine Automation in 2025

The CNC machine market is poised for significant growth, projected to increase from $101.22 billion in 2025 to $195.59 billion by 2032, reflecting a robust CAGR of 9.9%. This expansion underscores the rising demand for precision engineering and automation technologies that enhance production efficiency and output quality. Key advancements in CNC machine automation are set to redefine manufacturing processes, with technologies like AI and robotics leading the charge. These innovations are not just enhancing operational capabilities but are also supporting the trend toward smarter, more integrated manufacturing ecosystems.

The recent unveiling of new product lines, such as those entering the laser powder bed fusion market, highlights the industry's commitment to embracing additive manufacturing technologies. This move is expected to catalyze growth within the precision turned product manufacturing segment, which is anticipated to reach $196.11 billion by 2034, growing from an estimated $115.39 billion in 2025. These developments indicate that future CNC machines will increasingly incorporate intelligent features, driving automation in ways that significantly sharpen competitive edges for manufacturers.

Impact of AI and Machine Learning on CNC Machine Performance and Efficiency

As the CNC machine market evolves with the integration of AI and machine learning, the impact on performance and efficiency becomes increasingly profound. The anticipated growth in the

machine tool software market—from $3.12 billion in 2024 to $5.67 billion by 2033—highlights a crucial trend: the optimization of CNC systems through advanced algorithms. These technologies enable machines to analyze performance metrics in real-time, leading to more responsive and adaptive manufacturing processes.

Moreover, the push toward environmentally sustainable solutions in manufacturing drives the demand for eco-friendly CNC machines that maintain high precision without the traditional energy consumption. With the shift from conventional operations to automated solutions, manufacturers can significantly enhance productivity while meeting stringent efficiency standards. The ongoing innovation in AI capabilities promises to facilitate smarter production lines, ultimately transforming the landscape of precision engineering.

Evaluating the Top 10 CNC Machines: Key Features and Specifications to Consider

When evaluating the top 10 CNC machines for 2025, several key features and specifications emerge as critical factors in precision engineering and automation. According to a recent report by MarketsandMarkets, the global CNC machine market is projected to reach $100 billion by 2025, driven by increasing demand for automation across various industries. Features such as high-speed machining, multi-axis capabilities, and advanced control systems are essential for enhancing productivity and precision.

For instance, high-speed spindle technology not only reduces cycle times but also improves surface finish quality, making it a must-have specification for modern CNC machines. Additionally, multi-axis machining allows for the simultaneous cutting of complex geometries, which is increasingly important in industries such as aerospace and automotive. The integration of IoT and smart manufacturing capabilities into CNC machines, as highlighted in a report by Deloitte, can facilitate real-time monitoring and predictive maintenance, further optimizing operational efficiency and reducing downtime.

Top 10 CNC Machines in 2025: Features and Specifications

This chart showcases the performance and specifications of the top 10 CNC machines in 2025, evaluating key aspects like accuracy, processing speed, and weight capacity.

Sustainability in CNC Manufacturing: Eco-Friendly Innovations for 2025

The focus on sustainability in CNC manufacturing is rapidly gaining traction as companies strive to integrate eco-friendly practices into their production processes. Innovations such as next-generation CNC routers are being developed with artificial intelligence capabilities that enhance efficiency while reducing environmental impact. For instance, recent announcements highlight the introduction of CNC machines that utilize advanced energy management systems, which can significantly lower carbon footprints during manufacturing. According to industry reports, the CNC machinery market is projected to reach $100 billion by 2026, reflecting a growing inclination towards sustainable technologies.

Furthermore, events like VietnamWood 2025 showcase the importance of automation and sustainable practices in various industries, emphasizing the shift towards greener manufacturing solutions. Reports indicate that the global market for sustainable manufacturing techniques is expected to grow by 9% annually, driven by increasing awareness of environmental issues and regulatory pressures. Companies are now prioritizing investments in technologies that promote recycling and waste reduction, confirming that sustainability will be a cornerstone of innovation in the CNC manufacturing landscape for 2025 and beyond.

Related Posts

-

Exploring the Future of Manufacturing: How CNC Machine Tools Revolutionize Precision Engineering

-

Discover the Best Techniques for CNC Turning Parts Manufacturing Efficiency

-

Unlocking Precision: How CNC Machining Parts are Revolutionizing Modern Manufacturing

-

Maximizing Efficiency and Precision in Manufacturing with CNC Lathe Technology Insights and Trends

-

Exploring the Future of Precision Engineering with CNC Turning Machines

-

Understanding the Benefits of Large Part CNC Machining for Precision Manufacturing