2026 Top Trends in CNC Parts for Precision Engineering and Manufacturing?

The world of precision engineering and manufacturing is rapidly evolving. In 2026, trends in CNC parts are shaping the industry. These parts are vital for producing high-quality, accurate components. As technology advances, the demand for CNC parts continues to rise.

Manufacturers are increasingly focused on sustainability. They want to reduce waste and increase efficiency. This shift may lead to innovations in materials and processes. However, not all companies are keeping pace. Some struggle to adapt to these changes. This could lead to missed opportunities in a competitive market.

Keeping up with trends is essential. Integration of automation and smart technologies is on the rise. Companies that embrace these changes will likely excel. Yet, there are challenges to overcome. Not every manufacturer has access to the latest tools and training. As we move forward, the landscape of CNC parts will constantly change, presenting both risks and rewards.

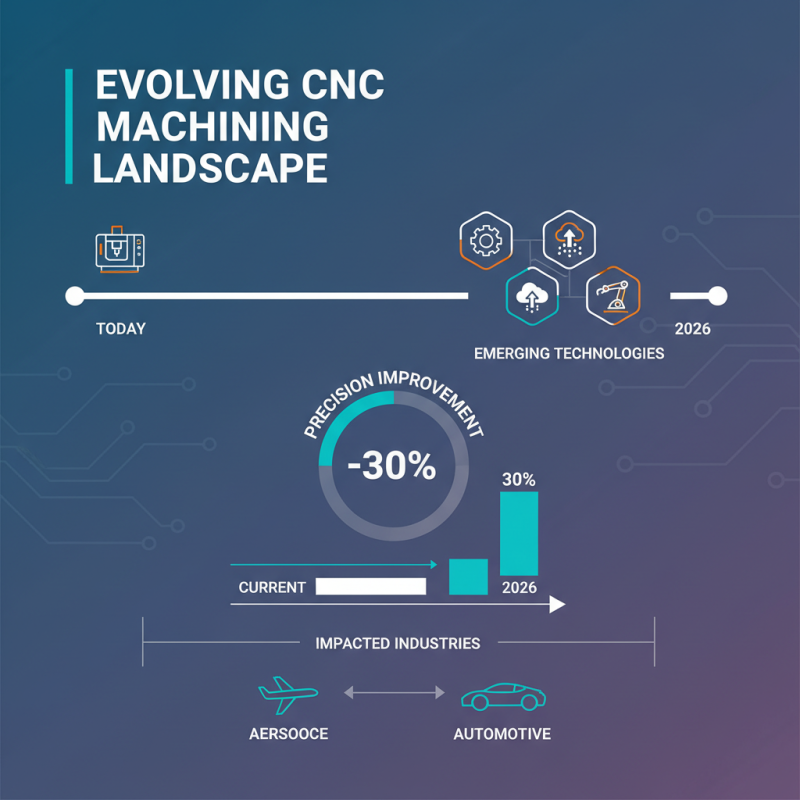

Emerging Technologies in CNC Machining for Enhanced Precision in 2026

The landscape of CNC machining is evolving rapidly. By 2026, emerging technologies promise to revolutionize precision engineering. Data indicates that the adoption of advanced solutions could improve precision by around 30%. This will significantly impact industries like aerospace and automotive, where accuracy is crucial.

Artificial intelligence and machine learning are set to enhance CNC machining. They can optimize processes and predict maintenance needs. Companies using AI tools have noted efficiency gains of up to 25%. Integrating real-time data analytics is a game changer for precision manufacturing. This allows for immediate adjustments during production, ensuring consistent quality.

**Tips:** Embrace automation. Invest in technology that reduces human error. Continuously train your staff on new tools and techniques. The future holds immense potential, but businesses must adapt to stay competitive. Remember, investing smartly in technology is non-negotiable for success.

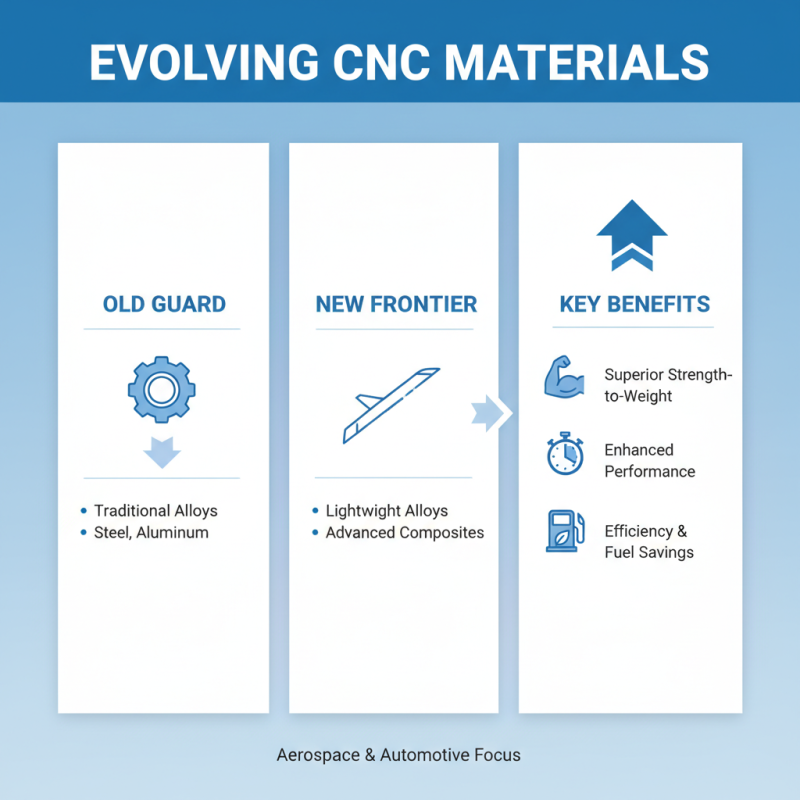

Trends in Material Selection: Lightweight Alloys and Composites for CNC Parts

The selection of materials for CNC parts is evolving rapidly. Lightweight alloys and composites are gaining popularity in precision engineering. These materials offer superior strength-to-weight ratios, which significantly enhance performance. In aerospace and automotive sectors, every gram counts. Components made from these materials can reduce overall weight, leading to better efficiency and fuel savings.

However, not every alloy or composite is perfect for every application. Some may lack durability or corrosion resistance. Engineers often face challenges in balancing weight and strength. Testing multiple materials can be time-consuming and costly. Additionally, there are concerns about the environmental impact of sourcing raw materials. This complexity requires careful consideration in the design process.

Despite the advancements, manufacturers must remain vigilant. The rapid pace of innovation can sometimes lead to oversights. It’s crucial to penetrate deeper into how these materials behave under different conditions. Future designs must not only focus on lightness but also on sustainability. Thoughtful material choices will inevitably shape the landscape of CNC machining in the years to come.

Impact of Automation and Robotics on Efficiency in Precision Manufacturing

Automation and robotics are revolutionizing precision manufacturing. These technologies enhance efficiency and precision. However, there are complexities to consider. For example, robots excel in repetitive tasks but struggle with intricate, creative decisions. This limitation can hinder overall productivity.

The integration of automation allows for higher production rates. Machines can operate continuously, reducing downtime. Yet, reliance on automation raises concerns about job displacement. Workers must adapt to new roles. Upskilling is crucial to thrive in this evolving landscape. A balance between human oversight and machine efficiency is essential.

Moreover, the implementation of robotics in CNC parts production can lead to system vulnerabilities. As machines take over, cybersecurity risks increase. Data breaches could halt operations. Companies must invest in safeguards against such threats. Innovation brings challenges, requiring constant evaluation and adaptation in manufacturing processes.

Sustainability Practices in CNC Manufacturing: Eco-Friendly Trends for 2026

Sustainability in CNC manufacturing is becoming increasingly important. As we look toward 2026, eco-friendly practices are gaining traction. Many companies are exploring sustainable materials. For example, biodegradable composites and recycled metals are popular choices. These materials reduce waste and energy consumption.

Another trend is reducing energy use. Advanced techniques, like energy-efficient CNC machines, are on the rise. They consume less power during operation. This leads to lower emissions and operational costs. Plus, companies are investing in renewable energy sources. Solar and wind energy are viable options for power supply.

Challenges remain in implementing these practices. Initial costs can be high. Some manufacturers may struggle to adapt to new technologies. Not all organizations have the resources for such transitions. However, the long-term benefits are significant. Sustainability can improve brand image and attract eco-conscious clients. Adopting these trends can reshape the CNC industry for a better future.

Market Growth Predictions for CNC Components in the Precision Engineering Sector

The market for CNC components in precision engineering is expected to grow significantly by 2026. This growth is driven by increased demand for high-quality, precise parts in various industries. As manufacturers focus on efficiency and accuracy, the relevance of CNC technology becomes more pronounced. Machine shops are rising to the challenge of producing intricate designs that meet strict specifications.

Emerging technologies like automation and AI are shaping this market. These advancements enable faster production and better quality control. However, some companies struggle to adapt to these innovations. The complexity of integrating new technologies can overwhelm certain businesses. They may miss opportunities for growth. As trends shift, traditional manufacturers face pressure to evolve or risk falling behind.

Environmental considerations also impact market predictions. Sustainable manufacturing practices are becoming essential. Companies must find ways to balance efficiency with eco-friendly practices. This shift often requires reevaluation of existing operations. Some firms may find it tough to implement these changes effectively. The journey ahead is filled with challenges but also vast potential for those willing to innovate.

2026 Top Trends in CNC Parts for Precision Engineering and Manufacturing

This chart illustrates the projected growth of various CNC components in the precision engineering sector from 2023 to 2026. The data reflects the increasing demand for CNC parts driven by advancements in technology and trends in manufacturing.

Related Posts

-

Top 10 Precision CNC Techniques for Maximum Efficiency in Manufacturing?

-

Top 10 CNC Milling Machines for Precision Machining in 2023

-

Discover the Best Techniques for CNC Turning Parts Manufacturing Efficiency

-

Unlocking Precision: How CNC Machining Parts are Revolutionizing Modern Manufacturing

-

2025 How to Optimize Brass CNC Machining for Increased Efficiency

-

Why Choosing the Right CNC Parts is Essential for Your Machinery Performance