2026 Top Trends in Large Part CNC Machining Technology?

In the dynamic field of large part CNC machining, innovation drives success. Renowned expert John Smith emphasizes, "Technology is advancing, but precision remains the core of large part CNC machining." As we approach 2026, several key trends are emerging.

Industry professionals are focusing on automation and digital integration. Smart machines now analyze data in real time, enhancing performance. Companies are investing in employee training to adapt to these new technologies.

Sustainability is another vital trend. Machining firms explore eco-friendly materials and processes. While these advancements are promising, challenges remain. The industry must continuously adapt to maintain high standards. The future of large part CNC machining depends on balancing innovation with precise execution.

Advancements in CNC Machining Technology for Large Parts

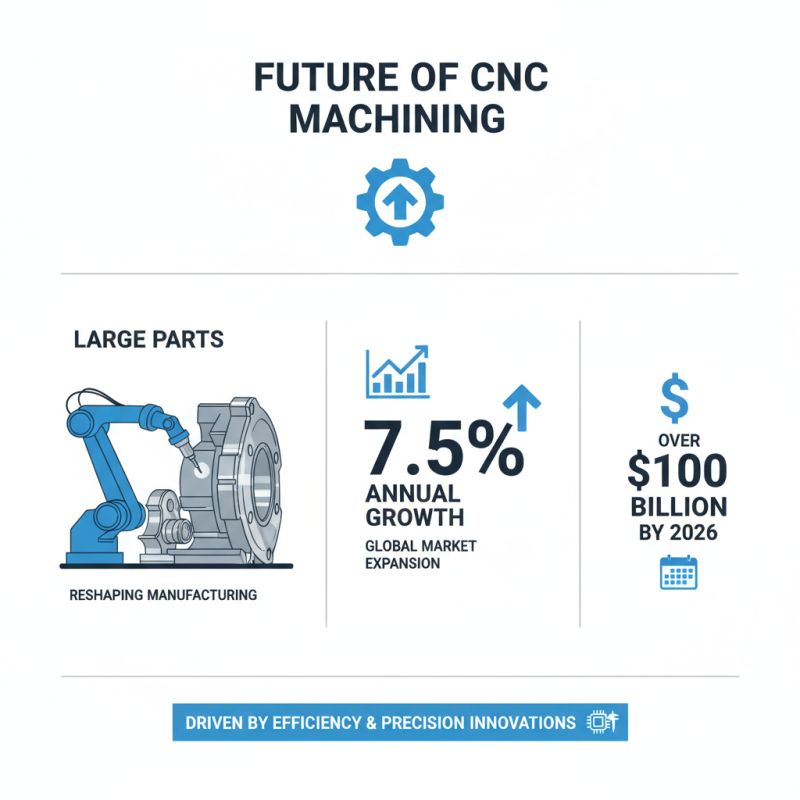

Advancements in CNC machining technology for large parts are reshaping the manufacturing landscape. Recent industry reports indicate that the global CNC machining market is expected to grow by 7.5% annually, reaching over $100 billion by 2026. This growth is driven by innovations that improve efficiency and precision.

One key development is the introduction of advanced materials. These new materials enable manufacturers to reduce weight while maintaining structural integrity. For instance, lightweight alloys and composites are gaining popularity. They present challenges in machining, but the recent advancements in cutting tools have addressed some of these issues. There’s still a need for further refinement. Some tools still show wear quicker than expected, impacting production schedules.

Another trend involves automation and artificial intelligence integration. Automated CNC systems offer increased accuracy. However, companies face high initial costs. Integrating AI can create complexities that require skilled operators. Not all facilities are equipped to manage these technologies effectively. Data from a recent survey suggested that nearly 40% of manufacturers struggle with implementing AI. Continuous training and investment will be crucial as the industry adapts.

Emerging Materials and Their Impact on Large Part CNC Machining

Emerging materials are reshaping large part CNC machining. Advancements in composites and alloys are leading the charge. These materials offer strength and lightweight properties. This makes them ideal for aerospace and automotive sectors.

However, the integration of new materials is not without challenges. Machinists must adapt to varying cutting speeds and tool wear rates. Each material requires unique handling and processing techniques. This can lead to trial and error for manufacturers.

Additionally, cost implications cannot be ignored. While some materials are cheaper, others demand higher investments. This could impact budgeting and project timelines. The evolving landscape of CNC machining needs continual learning. Businesses must stay informed to remain competitive.

Automation and Robotics in Large Scale CNC Machining Processes

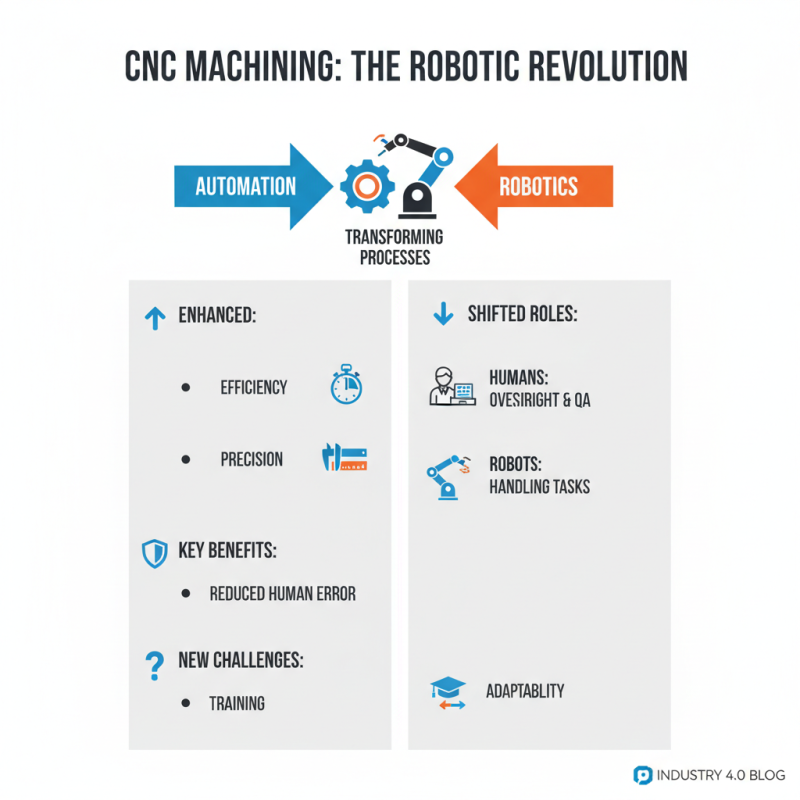

Automation and robotics are transforming large-scale CNC machining processes. These technologies enhance efficiency and precision, reshaping the workflow. With robots handling tasks, humans focus on oversight and quality control. This shift can reduce the risk of human error, but it raises new challenges in training and adaptability.

Adopting automation is not without hurdles. Many companies struggle to integrate new systems seamlessly. There can be a steep learning curve for operators. Additionally, investments in these technologies can be daunting, especially for smaller businesses. Finding the right balance between cost and innovation is essential.

Despite these challenges, the future looks promising. Automation boosts productivity and shortens lead times. By embracing robotics, companies can meet rising demands and improve consistency. However, continuous evaluation and adjustment are crucial as technology evolves. Organizations must remain flexible and responsive to maintain a competitive edge.

Sustainability Trends in Large Part CNC Machining Practices

Sustainability in large part CNC machining is becoming a critical focus. Reports indicate that by 2026, over 70% of manufacturers will prioritize green practices. This shift is partly due to regulatory pressures and consumer demand for eco-friendly products. Many companies are exploring alternative materials and recycling strategies. This helps reduce waste and carbon footprints.

Energy-efficient machinery is another trend. Many CNC machines now feature lower energy consumption rates. A recent study highlighted that adopting these machines could reduce energy use by 25%. However, not all manufacturers have the resources to invest in new technologies. Upgrading machinery can be costly, causing hesitation among smaller companies.

Waste management practices are evolving too. Implementing effective recycling processes is essential. Companies are encouraged to reclaim scrap materials. Yet, only about 40% of CNC machining firms actively recycle their waste. This reveals a gap in practice that needs addressing. Improving these processes could lead to significant environmental benefits.

2026 Top Trends in Large Part CNC Machining Technology

This chart illustrates the projected focus areas in sustainability trends within large part CNC machining practices, highlighting the importance of eco-friendly technologies and practices in the industry.

Future Innovations: AI and Machine Learning in CNC Machining

The integration of AI and machine learning in CNC machining is set to revolutionize the industry by 2026. Recent studies show that 42% of manufacturers plan to adopt these technologies within the next three years. This trend indicates a shift towards smarter and more adaptable machining processes. AI can optimize tool paths and predict maintenance needs, reducing downtime and costs. However, challenges remain in implementation and workforce training.

Data analytics is playing a crucial role here. Machine learning algorithms can analyze vast amounts of operational data to improve efficiency. For instance, they can identify patterns in machining operations that lead to defects. While this technology promises significant improvements, it also raises questions about the reliability of algorithms in complex environments. The industry must balance innovation with validation.

Moreover, the human aspect cannot be ignored. Operators must understand AI outputs to make informed decisions. Many companies face barriers, such as resistance to change and lack of expertise. As a result, a thoughtful approach is essential. Stakeholders need to consider the implications of automation on jobs. Engaging the workforce in this transition is critical for sustainable growth in CNC machining.

2026 Top Trends in Large Part CNC Machining Technology

| Trend | Description | Impact Level | Projected Adoption Rate (%) | Year of Expected Mainstream Use |

|---|---|---|---|---|

| AI Integration | Utilizing AI algorithms to enhance machining efficiency and accuracy. | High | 75% | 2026 |

| Adaptive Machining | Systems that adapt in real-time to changes in material or conditions. | Medium | 60% | 2025 |

| IoT Connectivity | Connecting CNC machines to the internet for data monitoring. | High | 80% | 2026 |

| Automation & Robotics | Incorporation of robotic systems for loading and unloading parts. | High | 70% | 2025 |

| Virtual Reality (VR) Training | Using VR technology for training operators in CNC machining. | Medium | 50% | 2024 |

| Sustainability Practices | Implementing eco-friendly materials and processes in machining. | High | 65% | 2026 |

Related Posts

-

Understanding the Benefits of Large Part CNC Machining for Precision Manufacturing

-

Top Benefits of Using Machined Parts in Modern Manufacturing Processes

-

Top 10 CNC Turning Parts Manufacturers for Precision Engineering Solutions

-

Unlocking Precision: How CNC Machining Parts are Revolutionizing Modern Manufacturing

-

2026 Best CNC Milling Parts for Precision Engineering?

-

Top 10 Benefits of Using Prototype Machined Parts for Your Projects