How to Achieve Precision with Fast CNC Machining Techniques?

In the realm of fast CNC machining, precision is not just a goal; it’s a necessity. Renowned expert Dr. Emily Chen emphasizes this point by stating, "Accuracy in fast CNC machining is the key to success in today’s competitive landscape." Her statement highlights the critical nature of precision in manufacturing.

Fast CNC machining offers a rapid solution for production needs, but challenges persist. Maintaining accuracy while increasing speed can lead to imperfections. For example, tools may wear differently, impacting the final product quality. Companies must address these issues to ensure customer satisfaction.

Furthermore, while advanced technologies improve efficiency, they also require constant evaluation. Regular calibration and skilled operators are essential. A lapse in these areas can lead to costly mistakes. Thus, achieving precision in fast CNC machining remains a continuous journey rather than a final destination.

Understanding CNC Machining: Basics and Applications

CNC machining is a crucial manufacturing process. It involves computer-controlled tools to fabricate parts. This method is precise and efficient, making it popular in various industries. Understanding the basics of CNC machining is essential. The process typically starts with a digital design, often created in CAD software. This design is then converted into a machine-readable format.

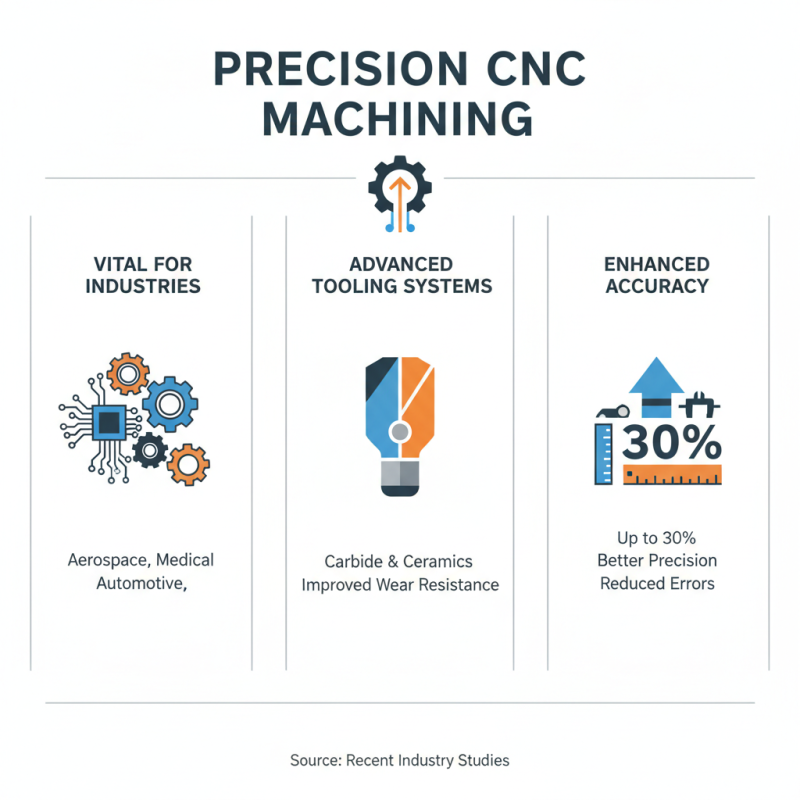

Applications of CNC machining are vast. It’s used in aerospace, automotive, and medical industries. Each sector has unique demands. For example, aerospace components need high precision and lightweight materials. These specialized requirements can complicate the machining process. Even experienced operators may face challenges. They must balance speed with accuracy.

While CNC machining offers numerous benefits, it’s not without flaws. Mistakes can occur during programming or tool setup. Sometimes, material properties may differ from expectations, leading to unexpected results. Continuous learning and adaptation are critical in the CNC world. Operators must regularly evaluate their processes to achieve the best outcomes.

Key Factors Influencing Precision in CNC Machining

Achieving precision in CNC machining relies on several key factors. One primary aspect is the machine's calibration. Regular calibration ensures that the CNC machine operates within tight tolerances. A machine that is out of alignment can lead to inaccuracies. It is crucial to check these settings before beginning any project.

Another influencing factor is the choice of tooling. The right tools can significantly affect the machining outcomes. Dull or inappropriate tools tend to produce rough, imprecise cuts. Additionally, tool wear needs close monitoring. Using a worn tool can introduce inconsistencies in dimensions.

The machining environment also plays an important role. Temperature and humidity variations may affect materials and machining accuracy. Thus, maintaining a controlled environment is essential. Operators should also be mindful of their techniques. Rushing through processes can lead to errors. Reflection on past projects often reveals room for improvement. Each mistake is a learning opportunity in the pursuit of perfection.

How to Achieve Precision with Fast CNC Machining Techniques? - Key Factors Influencing Precision in CNC Machining

| Factor | Description | Impact on Precision | Example Value |

|---|---|---|---|

| Machine Calibration | Regular adjustment of machine settings | High | 0.005 mm |

| Tool Wear | Degradation of cutting tools over time | Medium | 0.02 mm increase |

| Material Quality | The type and condition of the material being machined | High | Affects surface finish |

| Tool Path Optimization | Planning the most efficient path for cutting | High | Reduced cycle time |

| Cooling Techniques | Use of coolants to prevent overheating | Medium | Temperature control within 1°C |

Fast CNC Machining Techniques: Principles and Methods

Fast CNC machining techniques offer a streamlined approach to producing precise components. These methods rely on advanced technology and engineering principles. Machine operators must understand the intricacies of tooling, materials, and cutting speeds. A well-calibrated machine can significantly impact the precision of the final product. However, mistakes can occur. Misaligned tools or incorrect settings may lead to defects. Continuous monitoring of processes is essential to avoid these issues.

Understanding the principles behind fast CNC machining helps in refining techniques. The use of high-speed machining often allows for quicker production cycles. This can be beneficial for larger volumes but can pose challenges when dealing with intricate designs. Operators should be mindful of tool wear and the effects of different materials on machining speed. Fine-tuning parameters based on specific project requirements can enhance precision.

Mistakes in machining may occur due to oversights, such as overlooking the cooling system. Proper cooling is crucial to avoid overheating, which can warp the materials. Operators need to maintain a balance between speed and quality. Failing to do so can compromise the integrity of the work. In fast CNC machining, precision is not just about speed; it’s a continuous learning process.

Tools and Technologies for Enhanced Machining Precision

Achieving precision in CNC machining is vital for many industries. The right tools and technologies can significantly improve accuracy. Recent studies indicate that advanced tooling systems can enhance machining precision by up to 30%. These systems often incorporate materials like carbide and ceramics, which offer better wear resistance.

Automation is another crucial aspect. The integration of robots and AI into CNC machinery can streamline processes. For example, automated tool changers can reduce setup time and errors. However, rapid advancements also bring challenges. Many companies may struggle to keep up with new technologies, risking potential setbacks in production.

Additionally, software advancements in CAD/CAM systems facilitate precise modeling. These tools allow for intricate designs, minimizing human error. Yet, reliance on software necessitates regular training. Employees must stay updated with the latest updates to maximize efficiency. Overall, while tools and technologies can improve precision, businesses must also adapt to the fast-paced changes in the CNC landscape.

Quality Control Measures in CNC Machining Processes

Quality control is crucial in CNC machining processes. It ensures that every part meets specifications and functions properly. Various techniques help in maintaining this quality. Regular inspections during and after machining can identify defects early. Implementing statistical process control can monitor variations in production. This method tracks metrics and helps adjust processes as needed.

Despite these techniques, challenges remain. Variability in materials can lead to unexpected results. Sometimes, minor errors go unnoticed during the initial inspection phase. It's essential to review processes regularly and recalibrate machines. Establishing a culture of continuous improvement is vital. Workers should feel empowered to report discrepancies without fear. This can significantly enhance overall product quality.

Proper documentation is another key aspect of quality control. Keeping detailed records of machining parameters promotes traceability. However, paperwork can sometimes be a burden. Balancing documentation with efficient production is a challenge. Finding that balance is necessary for maintaining high standards. Fostering open communication between teams can mitigate misunderstandings and enhance accuracy.

Related Posts

-

Top Benefits of Fast CNC Machining for Your Manufacturing Needs

-

2026 Best CNC Milling Parts for Precision Engineering?

-

Exploring the Future of Manufacturing: How CNC Machine Tools Revolutionize Precision Engineering

-

Top 10 Benefits of Fast CNC Machining for Your Manufacturing Needs

-

Unlocking Precision: How CNC Machining Parts are Revolutionizing Modern Manufacturing

-

Top 10 Best CNC Machining Prototyping Services for Your Projects?