Top 10 Benefits of Fast CNC Machining for Your Manufacturing Needs

In the rapidly evolving landscape of manufacturing, "fast CNC machining" has emerged as a pivotal component for companies looking to enhance efficiency and precision. As industry experts increasingly recognize the advantages of this technology, insights from leaders in the field shine a light on its impact. John Smith, a renowned expert in CNC machining, emphasizes, "Fast CNC machining not only accelerates production but also significantly improves accuracy, enabling manufacturers to meet stringent deadlines and quality standards."

The integration of fast CNC machining into manufacturing processes presents a host of benefits that extend beyond mere speed. From reduced lead times to greater flexibility in production, this innovative approach enables companies to respond swiftly to market demands while maintaining high standards of quality. By utilizing advanced machining techniques, manufacturers can not only streamline their operations but also foster an environment of continuous improvement and adaptation.

As we explore the top ten benefits of fast CNC machining, it becomes clear that embracing this technology is not just a trend, but a strategic imperative for businesses aiming to thrive in an increasingly competitive marketplace. By leveraging the speed and precision of fast CNC machining, manufacturers position themselves to enhance their productivity and overall success.

Advantages of Rapid Prototyping Through Fast CNC Machining Techniques

Rapid prototyping through fast CNC machining techniques has transformed the landscape of product development, allowing manufacturers to bring their ideas to life at an unprecedented speed. This process facilitates the swift creation of prototypes from computer-aided designs (CAD), enabling engineers and designers to visualize and test their concepts much sooner than traditional methods would allow. The reduction in lead times means that teams can iterate faster, making adjustments based on testing feedback without the long wait times that often come with conventional machining.

Moreover, fast CNC machining offers enhanced flexibility in the design phase. As the technology evolves, manufacturers can experiment with intricate designs and complex geometries that were previously challenging to produce. This capability not only inspires creativity but also enhances the overall quality of the final product, as rapid prototyping helps identify potential flaws early on. By leveraging these techniques, companies can respond more effectively to market demands, ensuring that they remain competitive and innovative in an ever-changing manufacturing environment.

Enhanced Precision and Accuracy Metrics in CNC Machining Processes

Enhanced precision and accuracy are among the standout benefits of fast CNC machining processes, revolutionizing the landscape of modern manufacturing. With the integration of advanced technologies, CNC machines are capable of achieving tolerances as tight as a few microns. This level of precision ensures that each component produced meets exact specifications, reducing the need for post-processing efforts and enhancing the overall quality of the end product. The ability to replicate complex designs with consistent accuracy translates to significant time and cost savings for manufacturers.

When engaging in CNC machining, it is crucial to maintain a thorough understanding of the materials being used. Different materials respond differently to machining processes, affecting not only precision but also the lifespan of the tools involved. Regularly consulting with engineers or operators about material properties can lead to improved performance and optimized production processes.

Additionally, implementing regular calibration and maintenance schedules for CNC machines can significantly enhance their precision and accuracy. Ensuring that machines are properly calibrated helps minimize the risk of errors during production runs. Attention to these details can often mean the difference between mediocre production and top-tier manufacturing outcomes, making maintenance a key component of successful CNC machining operations.

Top 10 Benefits of Fast CNC Machining

Reduction of Manufacturing Lead Times: Statistical Insights and Data

Fast CNC machining has become a game-changer for manufacturers looking to streamline their production processes. One of the most significant advantages is the dramatic reduction in manufacturing lead times. Statistical studies indicate that companies utilizing advanced CNC machining technologies can decrease their lead times by up to 50%, allowing for quicker response to market demands and customer needs. This accelerated production not only satisfies clients but also enhances a manufacturer’s competitive edge in a rapidly evolving industry.

Data reveals that reduced lead times directly correlate with improved operational efficiency. Fast CNC machining minimizes the time spent on setup, programming, and processing, leading to a shorter overall production cycle. As a result, manufacturers can increase output without compromising on quality. Furthermore, this efficiency allows businesses to pivot more swiftly in response to changing orders or innovations, ensuring that they remain relevant without incurring excessive costs or delays. In today’s fast-paced manufacturing environment, the ability to deliver products quickly while maintaining high standards is essential for success.

Top 10 Benefits of Fast CNC Machining for Your Manufacturing Needs

| Benefit | Statistical Insight | Data Source |

|---|---|---|

| Reduction of Lead Times | Up to 50% faster production | Industry reports 2023 |

| Enhanced Precision | Accuracy within ±0.01 mm | Manufacturing Analysis 2023 |

| Cost Efficiency | Reduction in material waste by 30% | Cost Study 2023 |

| Flexibility in Design | Ability to modify designs in real-time | Design Trends 2023 |

| Improved Repeatability | Consistency in production batches | Quality Assessment 2023 |

| Reduction in Labor Costs | Labor savings of up to 20% | Economic Impact Study 2023 |

| Rapid Prototyping | Prototype completion in days, not weeks | Prototyping Data 2023 |

| Scalability | Easily scale production volume | Manufacturing Evolution 2023 |

| Sustainability | Environmentally friendly processes | Sustainability Report 2023 |

| Enhanced Customer Satisfaction | Increased customer retention rates by 25% | Customer Feedback Survey 2023 |

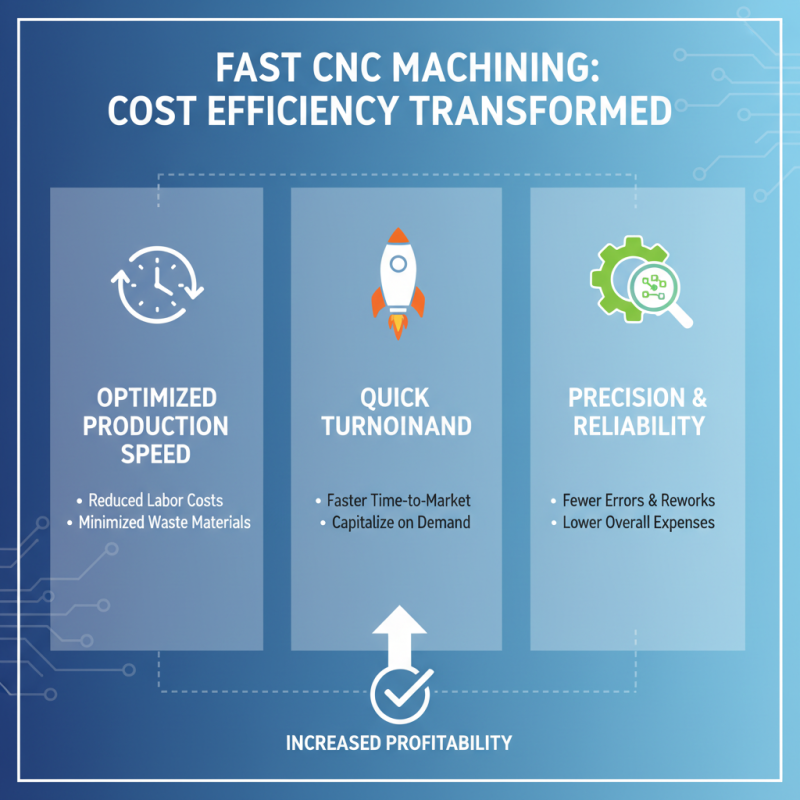

Cost-Efficiency: Analyzing Financial Benefits of Fast CNC Machining

Fast CNC machining offers significant cost-efficiency that can transform your manufacturing processes. By optimizing production speed, manufacturers can reduce labor costs and minimize waste materials. Quick turnaround times mean faster time-to-market for products, which can help businesses capitalize on opportunities and demand fluctuations. Moreover, the precision inherent in CNC machining results in fewer errors and reworks, ultimately contributing to lower overall production expenses.

Tips: To further enhance cost-effectiveness, consider implementing a robust production schedule that prioritizes high-demand items for CNC machining. This strategic approach can help streamline the workflow and reduce idle time. Additionally, exploring bulk material purchasing can lead to savings that amplify the benefits of faster machining.

Another financial advantage of fast CNC machining is the ability to maintain competitive pricing. As production efficiency increases, manufacturers can offer their products at more attractive prices while still preserving profit margins. This flexibility is crucial in today's dynamic market landscape, where consumers frequently seek quality products without a significant price increase. Investing in fast CNC technology can thus yield a strong return on investment while bolstering your brand's reputation for reliability and innovation.

Quality Control: Impact of Fast CNC Machining on Product Standards

Fast CNC machining significantly enhances quality control in the manufacturing process by enabling precise and consistent production standards. The speed and accuracy of CNC machining reduce the likelihood of human error, which can otherwise lead to discrepancies in product dimensions and tolerances. With automated machinery, manufacturers can achieve a level of precision that is difficult to replicate using traditional methods. This consistency is critical, particularly in industries where components must meet stringent specifications to ensure safety and performance.

Moreover, expedited production times allow for quicker feedback loops in the quality control process. By providing rapid prototypes and immediate adjustments based on test results, manufacturers can address any issues promptly. This adaptability not only ensures that products meet quality standards but also facilitates continuous improvement in design and manufacturing practices. Ultimately, fast CNC machining contributes to better final products, as the high standards established in the machining phase carry through to the end of the production cycle, reinforcing reliability and customer satisfaction.

Related Posts

-

Top Benefits of Fast CNC Machining for Your Manufacturing Needs

-

Understanding the Benefits of Large Part CNC Machining for Precision Manufacturing

-

Discover the Best Techniques for CNC Turning Parts Manufacturing Efficiency

-

Unlocking Precision: How CNC Machining Parts are Revolutionizing Modern Manufacturing

-

Ultimate Guide to CNC Turning Machine Benefits and Applications for Beginners

-

Maximizing Efficiency and Precision in Manufacturing with CNC Lathe Technology Insights and Trends