Top Benefits of Using Machined Parts in Modern Manufacturing Processes

In the ever-evolving landscape of modern manufacturing, the significance of machined parts cannot be overstated. As industries increasingly lean towards precision and efficiency, the role of these components has become a cornerstone of innovation. Industry expert John Smith, a prominent figure in machining technology, aptly stated, "The future of manufacturing hinges on the ability to produce high-quality machined parts that meet the demands of both complexity and speed." This perspective highlights the urgency for manufacturers to integrate machined parts into their operations to stay competitive.

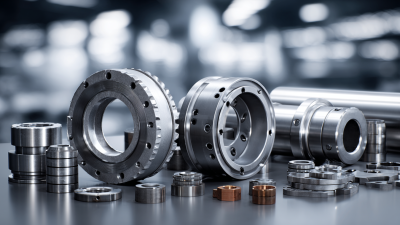

Machined parts offer unparalleled advantages, including improved accuracy, reduced waste, and a greater ability to meet customized specifications. These components are meticulously crafted using advanced techniques, enabling manufacturers to achieve tight tolerances that are essential for modern applications. As processes become more intricate, the reliability and performance of machined parts ensure that businesses can deliver products that adhere to the highest standards.

Moreover, the adaptability of machined parts makes them suitable for a wide array of industries, from aerospace to automotive. Their capacity to withstand rigorous conditions while maintaining structural integrity positions them as vital assets in manufacturing. As the industry continues to innovate, the exploration of the benefits associated with using machined parts is not just advantageous; it is essential for those aiming to thrive in the contemporary market.

Benefits of Precision Engineering in Machined Parts

Precision engineering plays a crucial role in the production of machined parts, significantly enhancing the quality and performance of the final products. By utilizing advanced techniques and technologies, such as computer numerical control (CNC) machining, manufacturers can achieve high levels of accuracy and repeatability. This precision allows for tighter tolerances, resulting in parts that fit together seamlessly and function as intended. In industries where even the slightest deviation can lead to catastrophic failures, the importance of precision engineering cannot be overstated.

Moreover, the benefits of precision engineering extend beyond mere accuracy. By optimizing the design and manufacturing processes, companies can reduce waste and improve efficiency. This heightened level of control can lead to shorter lead times and decreased production costs, enabling manufacturers to respond swiftly to market demands. Additionally, the ability to create complex geometries with intricate details opens up new possibilities for innovation, allowing businesses to develop cutting-edge products that stand out in a competitive landscape. Ultimately, precision engineering in machined parts not only elevates the quality of the output but also contributes to the overall success and sustainability of modern manufacturing.

Enhancing Product Quality Through Machined Parts

The modern manufacturing landscape has increasingly recognized the vital role of machined parts in enhancing product quality. According to a report by the National Institute of Standards and Technology (NIST), precision in manufacturing is paramount, with a staggering 90% of manufacturers stating that product quality directly influences customer satisfaction and business performance. Machined parts, known for their high precision and repeatability, contribute significantly to achieving these quality benchmarks. By utilizing advanced machining techniques, manufacturers can create components that conform to tight tolerances, which in turn minimizes assembly issues and enhances overall product reliability.

Furthermore, the integration of machined parts in production workflows facilitates better material efficiency and waste reduction. The American Society of Mechanical Engineers (ASME) highlights that precision machining can reduce scrap rates by up to 30%, which not only improves the bottom line but also promotes sustainable practices within the industry. Additionally, as industries continuously seek to innovate, the consistent quality of machined components supports the development of more complex products that meet customer demands for performance and durability. In summary, the impact of machined parts on product quality is significant, driving improvements across the manufacturing spectrum and positioning businesses for long-term success in a competitive market.

Cost Efficiency and Waste Reduction in Manufacturing

The shift towards machined parts in modern manufacturing processes brings significant advancements in cost efficiency and waste reduction. According to a report by the National Institute of Standards and Technology (NIST), incorporating precision machining can lead to a reduction in material waste by as much as 30%. This is particularly crucial in an era where resource conservation is becoming a key competitive advantage. Machined parts are designed with precision, allowing for tighter tolerances and minimized excess material during production, ultimately resulting in lower costs for manufacturers.

Furthermore, the efficient utilization of materials through machining not only cuts down on waste but also decreases production costs. A study by the Manufacturing Industry Institute highlights that companies employing advanced machining techniques can achieve up to 15% savings in operational costs over traditional manufacturing methods. These savings can be attributed to reduced cycle times and the ability to use higher-quality materials that require less rework. As the manufacturing sector continues to evolve, the demand for efficiency and sustainability makes machined parts an increasingly valuable asset in achieving both cost-effectiveness and responsible resource management.

Top Benefits of Using Machined Parts in Modern Manufacturing Processes - Cost Efficiency and Waste Reduction in Manufacturing

| Benefit | Description | Impact on Cost (%) | Waste Reduction (%) |

|---|---|---|---|

| Precision Manufacturing | High accuracy and repeatability in part production. | 15% | 20% |

| Material Efficiency | Minimized waste through optimized material usage. | 10% | 25% |

| Shorter Lead Times | Faster production cycles due to efficient processes. | 20% | 15% |

| Customization Options | Ability to produce tailored parts to meet specific needs. | 5% | 10% |

| Reduced Rework | Lower rates of defects and errors lead to less rework. | 12% | 30% |

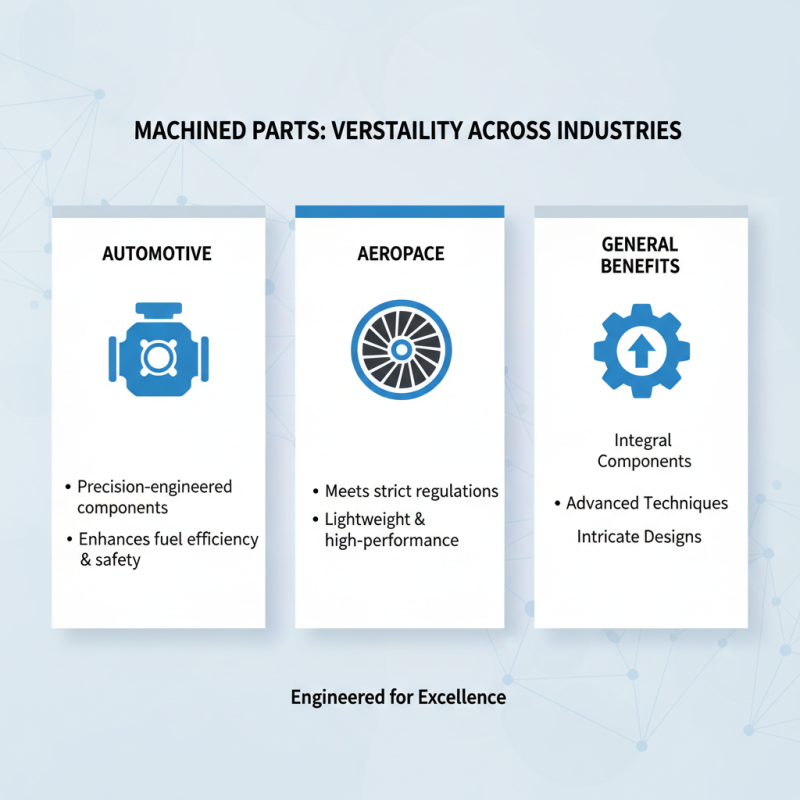

Versatility of Machined Parts Across Various Industries

Machined parts have become an integral component in various industries due to their unparalleled versatility. In the automotive sector, for instance, precision-engineered components ensure the reliability and performance of vehicles. These parts, crafted through advanced machining techniques, enable manufacturers to produce intricate designs that enhance fuel efficiency and safety. Similarly, the aerospace industry relies heavily on machined parts, which must meet strict regulations and standards. Here, the precision and lightweight properties of machined components are critical for maintaining performance in challenging environments.

Beyond automotive and aerospace, machined parts can be found across medical, electronics, and construction industries. In healthcare, custom-machined instruments and implants are essential for surgical applications, where precision can significantly impact patient outcomes. In electronics, machined parts facilitate the assembly of complex devices, allowing for miniaturization and improved functionality. The construction industry also benefits from machined components in the fabrication of durable machinery and structural elements that withstand immense stress. This adaptability to different requirements underscores the pivotal role of machined parts in driving innovation and efficiency across various industrial landscapes.

Advancements in Technology Influencing Machined Part Production

Advancements in technology have significantly transformed the production of machined parts, enhancing efficiency and precision in modern manufacturing processes. One of the key factors driving this evolution is the integration of computer numerical control (CNC) machining, which reportedly offers a precision level of up to 0.002mm. According to a market research report by Grand View Research, the global CNC machining market is expected to reach $87.69 billion by 2027, reflecting a compound annual growth rate (CAGR) of 6.2% from 2020. This rapid growth underscores the increasing adoption of CNC machines in various sectors, including aerospace, automotive, and medical, where high precision and custom solutions are paramount.

Moreover, the advent of additive manufacturing technologies, such as 3D printing, is reshaping traditional machining processes. As per a report by Wohlers Associates, the additive manufacturing industry grew to $12.8 billion in 2020, showcasing its rising prominence in producing complex geometries that were previously unachievable through conventional methods. These advanced technologies not only enable the fabrication of lighter and more robust components but also shorten lead times and reduce material waste. Consequently, manufacturers are now equipped to meet the demands of a rapidly evolving market while optimizing costs and improving production timelines.

Related Posts

-

Unlocking Innovation: The Vital Role of Machined Parts in Modern Manufacturing Advances

-

Exploring the Future of Precision Engineering with CNC Turning Machines

-

Top 10 Benefits of Using Prototype Machined Parts for Your Projects

-

Exploring the Future of Manufacturing: How CNC Machine Tools Revolutionize Precision Engineering

-

2025 How to Optimize Brass CNC Machining for Increased Efficiency

-

The Future of Brass CNC Machining Innovations and Trends in Precision Engineering