Top 10 Benefits of Using Prototype Machined Parts for Your Projects

In the rapidly evolving landscape of manufacturing and design, the demand for precision and efficiency has never been greater. Prototype machined parts have emerged as a crucial solution for industries seeking to streamline product development while minimizing costs. According to a recent industry report by the Manufacturing Institute, nearly 70% of companies using prototype machined parts reported reduced lead times and improved accuracy in their manufacturing processes. This underscores the significant role that these components play in advancing technological innovation.

Industry expert Dr. Emily Carter, a mechanical engineer with over twenty years of experience in prototyping, states, “Utilizing prototype machined parts allows companies to iterate and refine their designs swiftly—it’s a game changer for product development." Her insights highlight how these parts not only facilitate rapid prototyping but also enable teams to test functionality and design feasibility early in the process, ultimately leading to better product outcomes and satisfied customers. In light of these advantages, understanding the top benefits of incorporating prototype machined parts into project workflows can provide invaluable guidance for businesses aiming to stay competitive in their respective markets.

Benefits of Enhanced Precision in Prototype Machined Parts

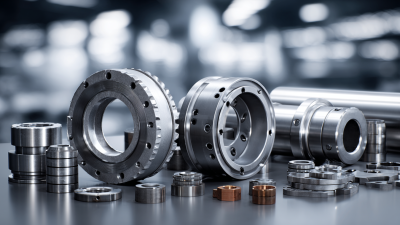

Enhanced precision in prototype machined parts is a game-changer for designers and engineers working on complex projects. When utilizing advanced machining techniques, manufacturers can achieve tolerances that are often within a few microns. This level of accuracy ensures that each part fits seamlessly within an assembly, reducing the likelihood of errors during final manufacturing. Such precision is crucial when dealing with intricate components, where even minor discrepancies can lead to significant performance issues or failures.

Additionally, the ability to produce prototypes with high precision accelerates the testing and validation process. Engineers can confidently assess the functionality and behavior of a part under real-world conditions, allowing for quicker iterations and refinements. The precision provided by prototype machined parts enables more accurate simulations during testing, leading to better-informed design decisions. Consequently, this focus on precision not only enhances the overall quality of the final product but also optimizes resource usage, ultimately driving efficiency and innovation in project development.

Streamlined Production Processes through Machined Prototypes

The adoption of digital manufacturing technologies, such as CNC machining and advanced prototyping techniques, has transformed production processes across various industries. By utilizing machined prototypes, companies can achieve streamlined production workflows that significantly reduce lead times and enhance overall efficiency. For instance, the integration of digital twin technology allows manufacturers to synchronize virtual models with real machines, ensuring high precision and minimizing errors during the production phase. This innovative approach not only accelerates prototyping but also facilitates seamless transitions to full-scale production.

In the boat manufacturing sector, the precision provided by advanced CNC parts has proven vital for enhancing quality and reducing waste. Reports indicate that the North America contract manufacturing services market was valued at approximately USD 64.5 billion in 2024, with a projected CAGR of 6.8% through 2030. As businesses increasingly leverage these digital solutions, the ability to rapidly prototype and develop products with accuracy becomes a competitive advantage. Furthermore, the evolution of reverse engineering techniques highlights an industry shift where innovation drives the journey from prototype to production, solidifying the importance of machined prototypes in modern manufacturing environments.

Cost-Effectiveness of Utilizing Machined Parts for Prototyping

Utilizing machined parts for prototyping offers significant cost-effectiveness, making it an ideal choice for many projects. One of the primary advantages is the reduction of material waste. Traditional manufacturing processes often require excess material that is trimmed away, resulting in higher costs. In contrast, precision machining methods, such as CNC machining, allow for the efficient use of raw materials, ensuring that only the necessary amount is utilized, which ultimately decreases material expenses.

Moreover, the speed of production with machined parts can lead to faster project timelines and reduced labor costs. Prototyping typically involves multiple iterations, and being able to produce high-quality components quickly means that teams can test designs effectively without incurring prohibitive expenses. This agility enables businesses to adapt and refine their products based on feedback, positioning them to stay competitive in fast-paced markets. Overall, the enhanced cost-effectiveness of machined parts in prototyping fosters innovation while keeping projects within budget.

Flexibility and Customization Options with Prototype Machining

Prototype machining offers unparalleled flexibility and customization options that are crucial for the successful execution of projects. The ability to quickly adapt designs allows companies to respond to market demands and client feedback with agility. According to a report by Grand View Research, the CNC machining market is expected to reach $100.38 billion by 2025, underscoring the growing reliance on prototype machined parts in various industries. This capability not only speeds up the development cycle but also minimizes expensive errors that can arise from ill-fitting parts or mismatched specifications.

When utilizing prototype machined parts, consider focusing on iterative design. Gathering feedback during each prototype iteration can lead to insights that significantly reduce production costs and enhance product performance. Additionally, always ensure you are working with a manufacturer that specializes in your specific material needs. This can enhance the end product's durability and functionality, ultimately providing a more advantageous product to your customers.

One key tip is to utilize software tools that can simulate the machining process. These tools can help identify potential issues before they arise on the shop floor, ensuring a smoother production experience. Also, embracing additive manufacturing techniques along with traditional machining methods can provide even greater customization options, allowing you to explore designs that other methods may not support.

Improved Testing and Validation of Design Concepts with Prototypes

Prototypes are essential in the design process, providing invaluable insights during testing and validation of concepts. By utilizing prototype machined parts, engineers and designers can quickly identify flaws and areas for improvement. The tactile nature of physical prototypes allows for real-world testing, enabling teams to assess functionality and performance before final production. This stage is critical as it helps to minimize costly revisions and ensures that the final product meets the intended specifications and user needs.

Tip: Always involve end-users during the prototype testing phase. Their feedback can offer unique perspectives that might uncover issues you hadn't considered. Additionally, consider using iterative prototyping, where you refine your design through multiple cycles of testing and feedback. This method not only enhances the final product, but it also fosters collaboration among team members.

Implementing prototype machined parts also streamlines the design process by allowing teams to utilize CAD software to simulate various scenarios. This virtual testing can highlight potential design flaws without the need for physical alterations. The combination of digital simulations and physical prototypes creates a robust framework for validating ideas, ultimately leading to better-performing products and reduced time-to-market.

Tip: Document each testing phase thoroughly, noting changes made and outcomes observed. This documentation is a valuable resource for future projects and may serve as guidance for troubleshooting in later stages of development.

Related Posts

-

Unlocking Innovation: The Vital Role of Machined Parts in Modern Manufacturing Advances

-

Exploring the Future of Precision Engineering with CNC Turning Machines

-

Unlocking Precision: How CNC Machining Parts are Revolutionizing Modern Manufacturing

-

Understanding the Benefits of Large Part CNC Machining for Precision Manufacturing

-

2025 Top 10 CNC Machines: Unveiling the Future of Precision Engineering and Automation

-

Maximizing Efficiency and Precision in Manufacturing with CNC Lathe Technology Insights and Trends