How to Choose the Best CNC Machining Prototyping Techniques for Your Project

In the rapidly evolving field of manufacturing, selecting the right CNC machining prototyping techniques is pivotal for the success of any project. According to a report by the Grand View Research, the global CNC machining market size was valued at approximately $63.43 billion in 2020 and is projected to expand at a compound annual growth rate (CAGR) of 5.6% from 2021 to 2028. This growth illustrates the increasing demand for precision and efficiency in production processes, underscoring the importance of effective prototyping techniques.

CNC machining prototyping not only enhances product design and development but also significantly reduces time-to-market. A study published by Industry Week revealed that companies utilizing advanced prototyping methods could shorten their product development cycle by 40%, leading to improved responsiveness to market demands. With various CNC machining techniques available, from subtractive methods to additive manufacturing, selecting the most suitable one based on specific project requirements is essential. This decision not only affects cost and turnaround time but also the quality and performance of the final product. As industries continue to push the boundaries of innovation, mastering the art of CNC machining prototyping will be integral in maintaining a competitive edge.

Understanding CNC Machining Prototyping and Its Importance in Manufacturing

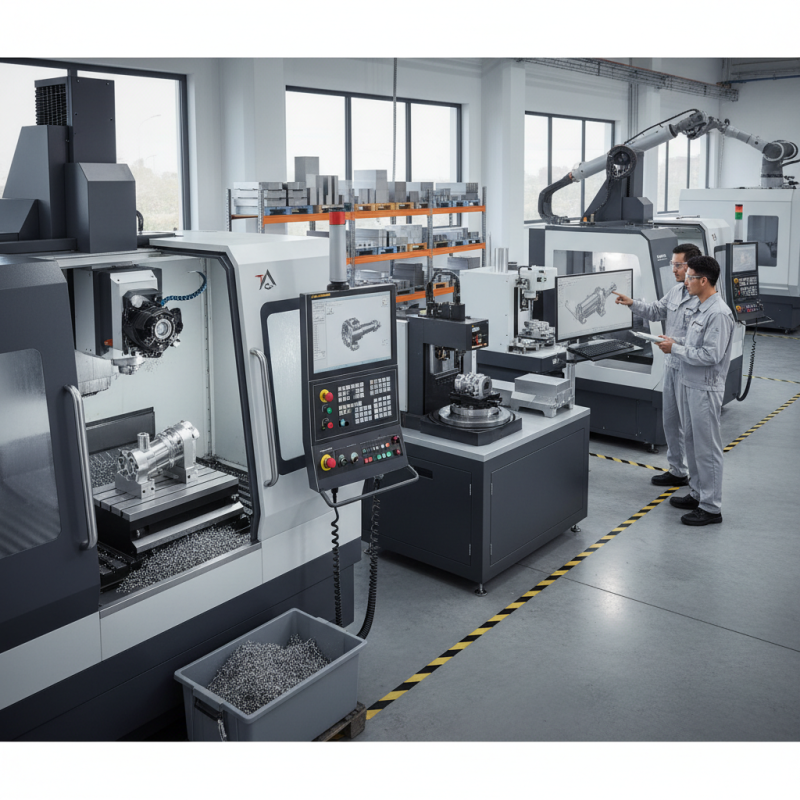

CNC machining prototyping plays a crucial role in modern manufacturing, serving as a vital bridge between design concepts and final products. This process utilizes computer numerical control technology to create precise and intricate parts from various materials, enabling manufacturers to rapidly transform digital models into tangible prototypes. The importance of CNC prototyping lies in its ability to minimize errors, reduce production time, and lower costs. By leveraging advanced machining techniques, businesses can test their designs effectively, ensuring that the final product meets both functional and aesthetic standards.

Additionally, CNC machining prototyping enhances the iterative design process. It allows engineers and designers to quickly produce multiple prototype iterations, facilitating thorough testing and validation. This flexibility is essential for identifying potential design flaws early, which can drastically cut down time and resources spent on later production stages. The ability to simulate different conditions and responses to material choices empowers manufacturers to make informed decisions, leading to innovations that might not have been possible without such prototyping techniques. As industries continue to evolve, the importance of CNC machining in prototyping will only grow, making it an indispensable tool for successful manufacturing practices.

Key Factors to Consider When Choosing CNC Machining Techniques

When selecting the best CNC machining prototyping techniques for your project, several key factors come into play. First and foremost, the material you intend to use is crucial. Different materials require specific machining processes for optimal results. For instance, metals like aluminum may necessitate different cutting speeds and tooling than plastics or composites. Understanding the properties of your chosen material helps in determining the most efficient and effective CNC technique, ensuring that the final prototype meets your project's specifications.

Another vital factor is the complexity of your design. CNC machining offers various methods, such as milling, turning, and wire EDM, each suited for different geometric intricacies. If your prototype has tight tolerances or complex features, you must choose a technique that provides the necessary precision and surface finish. Additionally, consider the scale of your project—whether you need single-piece prototypes or low-volume production can influence your choice. Balancing the complexity of the design with the capabilities of the chosen machining technique can lead to successful outcomes in prototyping.

Comparison of CNC Machining Prototyping Techniques

Comparison of Common CNC Machining Techniques: Materials and Applications

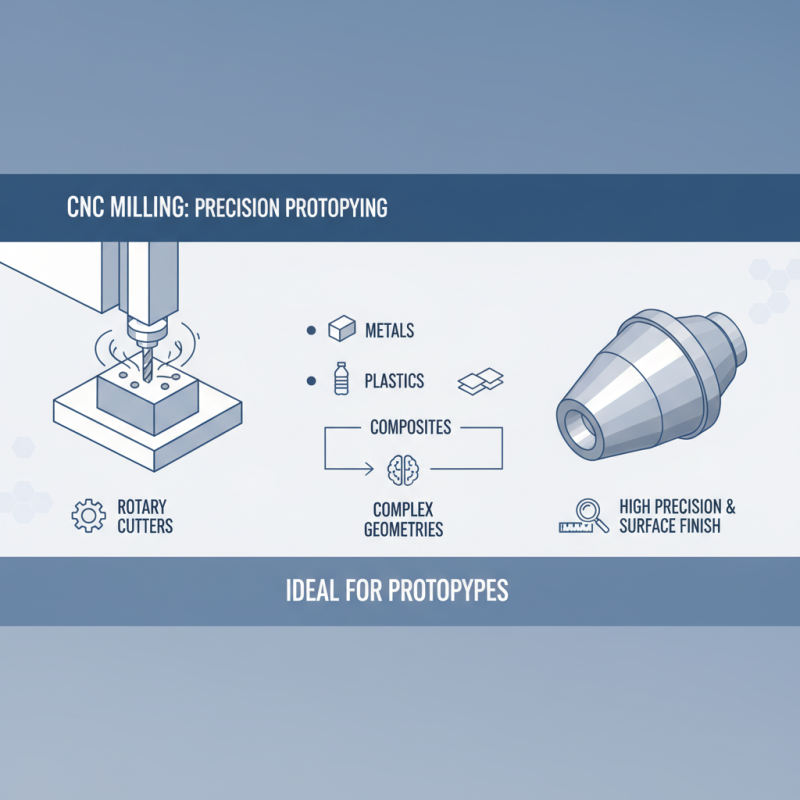

CNC machining encompasses various techniques, each suited for different materials and applications. One of the most common methods is milling, which utilizes rotary cutters to remove material from a workpiece. It is versatile and can handle a wide range of materials, including metals, plastics, and composites. Milling is ideal for creating complex geometries and intricate details, making it a preferred choice for prototypes that require high precision and surface finish.

Another frequently used technique is turning, where a workpiece is rotated against a stationary cutting tool. This method is particularly effective for cylindrical components and offers excellent dimensional accuracy. Turning can accommodate various materials, including softer metals and plastics. Applications typically include shaft production, bushings, and other cylindrical parts that require a smooth finish and tight tolerances.

For projects that necessitate quick iterations and revisions, additive manufacturing through CNC machining techniques like 3D printing can be advantageous. While traditionally classified separately, hybrid CNC systems now integrate additive techniques with subtractive processes. This allows for the production of complex structures and rapid prototyping without the limitations of material wastage associated with conventional methods. Thus, selecting the appropriate CNC technique for your project will significantly depend on material properties, desired tolerance levels, and the intricacies of the intended design.

Evaluating Cost Efficiency of CNC Machining Prototyping Options

When evaluating the cost efficiency of CNC machining prototyping options, the first step is to consider the specific requirements of your project. Factors such as material selection, complexity of design, and required tolerances all influence the overall costs. For instance, utilizing more common materials can significantly reduce expenses compared to using specialized alloys or composites. Additionally, simpler designs that require less machining time will generally lead to lower costs, allowing for a more budget-friendly prototyping process. Understanding these variables is essential to achieving a balance between design needs and financial constraints.

Another crucial aspect involves comparing various CNC machining techniques to identify the most economically viable options. While traditional milling and turning methods may be suitable for certain designs, advanced techniques such as additive manufacturing or hybrid machining might provide cost advantages for more intricate prototypes. It is also imperative to factor in the setup and operational costs associated with each technique, as these can vary significantly. By carefully analyzing these elements, project managers can make informed decisions that not only meet technical specifications but also align with budgetary limits, thus ensuring the selected prototyping method is both efficient and cost-effective.

How to Choose the Best CNC Machining Prototyping Techniques for Your Project - Evaluating Cost Efficiency of CNC Machining Prototyping Options

| Prototyping Technique | Material Types | Setup Cost | Production Cost per Unit | Lead Time | Ideal For |

|---|---|---|---|---|---|

| CNC Milling | Aluminum, Steel, Plastics | $500 | $20 | 2 weeks | Complex geometries |

| CNC Turning | Steel, Brass, Aluminum | $600 | $15 | 1.5 weeks | Cylindrical parts |

| 3D Printing | Plastics, Resins | $300 | $10 | 3 days | Rapid prototyping |

| Laser Cutting | Wood, Acrylic, Metals | $400 | $12 | 1 week | Flat parts and designs |

| EDM (Electrical Discharge Machining) | Tool Steel, Tungsten | $800 | $25 | 2.5 weeks | Intricate designs and cavities |

Future Trends in CNC Machining: Innovations and Technologies to Watch

The landscape of CNC machining is rapidly evolving, driven by innovations that enhance efficiency, precision, and versatility in prototyping. One of the most notable trends is the integration of artificial intelligence (AI) and machine learning, which are being utilized to optimize machining processes. According to a recent industry report, the AI-enabled CNC machining market is projected to grow by 35% annually, indicating a significant shift toward data-driven decision-making in manufacturing. This technology allows for real-time monitoring and predictive maintenance, reducing downtime and increasing productivity.

Another critical area of advancement is the adoption of additive manufacturing techniques alongside traditional CNC processes. Hybrid machining systems that combine subtractive and additive methods are gaining traction, offering manufacturers the ability to produce complex geometries and reduce material waste. Research from a prominent manufacturing technology network indicates that companies employing hybrid techniques can decrease production time by up to 50%, making it an attractive option for prototype development. As these innovations continue to develop, they promise to revolutionize CNC machining, making it more adaptable to the dynamic demands of modern industries.

Related Posts

-

Top Benefits of Fast CNC Machining for Your Manufacturing Needs

-

Ultimate Guide to CNC Turning Machine Benefits and Applications for Beginners

-

Discover the Best Techniques for CNC Turning Parts Manufacturing Efficiency

-

2025 Top 10 CNC Machines: Unveiling the Future of Precision Engineering and Automation

-

Top 5 Advantages of Using Prototype Machined Parts for Efficient Production

-

Top 10 Benefits of Fast CNC Machining for Your Manufacturing Needs