2026 Best CNC Milling Parts for Precision Engineering?

In the world of precision engineering, the demand for high-quality CNC milling parts is on the rise. According to a recent report by MarketsandMarkets, the CNC machining market is projected to reach $100 billion by 2026. This growth reflects the increasing reliance on precision parts in various industries, including aerospace, automotive, and medical devices. Experts highlight the need for innovation and quality control in this field.

John Carter, a renowned CNC machining specialist, emphasizes, “Quality CNC milling parts are crucial for maintaining operational efficiency.” This statement underscores the industry's commitment to precision and reliability. Companies must adapt to evolving technologies and maintain rigorous standards to ensure their CNC milling parts meet client expectations.

However, not all manufacturers prioritize these aspects. Some focus solely on cost-cutting, resulting in subpar products that compromise quality. This trend is concerning and calls for a reassessment of priorities in the CNC milling segment. As the industry evolves, delivering excellent CNC milling parts will become increasingly essential to meet the diverse needs of precision engineering applications.

Overview of CNC Milling in Precision Engineering

CNC milling is a crucial part of precision engineering. It involves removing material from a workpiece to create the desired shape. This process allows for high precision and accuracy, making it ideal for producing intricate parts.

When selecting CNC milling parts, think about the material. Options vary from aluminum to stainless steel. Each material has unique properties. Some are easier to machine, while others provide better durability. Always consider the application requirements.

Tips: Always check the tolerances you need. Slight variations can affect performance. Ensure your machine settings are calibrated. This minimizes errors and wasted material. It's easy to overlook small details, but they matter. Plan your workflow carefully to avoid unnecessary complications.

CNC milling requires skill and attention. Operators must understand the machinery and the materials used. Mistakes can occur, leading to scrap materials. Learning from errors is part of improvement. Don't hesitate to tweak your methods as needed.

Comparison of CNC Milling Parts Accuracy in Precision Engineering

Key Materials Used for CNC Milling Parts

CNC milling is revolutionizing the precision engineering sector. Different materials play a crucial role in shaping components.

Metals, plastics, and composites are widely used, each with unique properties. For instance, aluminum remains a favorite due to its lightweight nature and excellent machinability. According to a 2021 industry report, aluminum accounted for nearly 30% of all CNC-milled parts.

Plastics, like polycarbonate and nylon, are favored for their resistance to corrosion and lower weight. They are essential in producing intricate designs. A recent study revealed that the demand for plastic CNC parts increased by 15% over the past two years. However, challenges arise. Some plastics can warp under heat, affecting dimensional accuracy.

Composites, though more expensive, offer high strength-to-weight ratios. They are crucial in aerospace and automotive applications. A report showed that composite materials usage in CNC milling has grown by 10% annually. Still, machining these materials requires special tools and techniques. Many engineers face difficulties achieving the desired finish with composites, reflecting the need for ongoing refinement in machining methods.

Top CNC Milling Technologies for Precision Applications

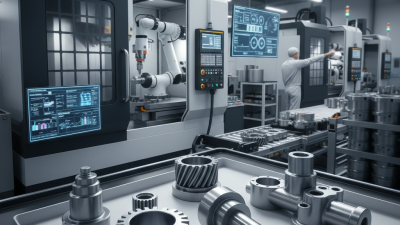

CNC milling technology has revolutionized precision engineering. It offers unmatched accuracy for various applications. These processes can produce complex shapes with tight tolerances. Some machines are equipped with advanced sensors. They ensure that every cut meets precise specifications. This technology can be seen in industries from aerospace to medical devices.

In precision applications, the choice of tools is vital. High-speed machining is becoming more common. It reduces production time while maintaining quality. Adaptive machining strategies help optimize efficiency. However, operators must be skilled to handle variations in materials. Not every setup will yield perfect results. An occasional miscalculation can lead to unexpected waste. Embracing these challenges can lead to improvement.

Choosing the right CNC technology is key. Different materials require different approaches. Metal, plastic, and composites all behave uniquely. Incorporating advanced software enhances design capabilities. However, the human element remains crucial. Ensuring proper communication between machines and operators can greatly influence outcomes. Mistakes may happen, but they often offer valuable insights.

Quality Control Standards in CNC Milling Processes

Quality control is vital in CNC milling processes. It ensures precision and reliability in parts produced for engineering applications. Implementing strict quality standards helps to reduce errors. This results in fewer machine adjustments and improved overall efficiency. Consistent monitoring can identify issues before they escalate.

Tips for maintaining quality control include regular equipment calibration. Check tools and machines for wear and tear. Minor misalignments can lead to major inaccuracies. Always inspect raw materials before production. Low-quality materials can compromise the final product. Create a checklist for quality assessments at various stages.

Creating a feedback loop with your team can also be beneficial. Encourage open communication about imperfections in the process. Reflect on mistakes to improve future production. Mistakes can provide learning opportunities. Analyze production data regularly to spot trends or recurrent issues. This proactive approach helps maintain high standards in CNC milling parts.

2026 Best CNC Milling Parts for Precision Engineering - Quality Control Standards in CNC Milling Processes

| Part Name | Material | Dimensions (mm) | Tolerances (mm) | Surface Finish | Quality Control Method |

|---|---|---|---|---|---|

| Base Plate | Aluminum 6061 | 150 x 100 x 10 | ±0.02 | Anodized | CMM Inspection |

| Housing | Stainless Steel 304 | 75 x 50 x 25 | ±0.05 | Electropolished | Visual Inspection |

| Bracket | Carbon Steel | 100 x 75 x 5 | ±0.1 | Powder Coated | Dimensional Check |

| Gear | Brass | 50 x 50 x 20 | ±0.01 | Smooth Finish | Functional Testing |

Future Trends in CNC Milling for Precision Engineering

CNC milling continues to evolve, impacting precision engineering significantly. Future trends highlight automation and smart technology as key components. Machines equipped with AI can enhance productivity. However, reliance on technology may introduce challenges. Operators must be skilled to collaborate efficiently with machines.

Investing in advanced software is crucial for precision. These tools can simulate the milling process, predicting outcomes effectively. Yet, they require proper training for optimal use. Many engineers overlook this step. Without skillful operation, glitches may occur, affecting quality.

Tips: Consider integrating sensors to monitor the milling process. They provide real-time data and improve accuracy. Regularly update training programs for staff to keep up with new technologies. Engaging employees in discussions on technology use often reveals hidden insights. Embrace these imperfections; they pave the way for improvement.

Related Posts

-

Discover the Best Techniques for CNC Turning Parts Manufacturing Efficiency

-

Why Choosing the Right CNC Parts is Essential for Your Machinery Performance

-

Top Benefits of Fast CNC Machining for Your Manufacturing Needs

-

Exploring the Future of Manufacturing: How CNC Machine Tools Revolutionize Precision Engineering

-

How to Choose the Best CNC Machining Prototyping Techniques for Your Project

-

Top 2025 CNC Mill Models: What to Consider for Precision Machining