2026 Best CNC Turning Center Features and Benefits Explained?

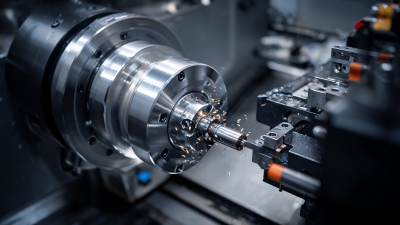

In the world of manufacturing, the demand for precision and efficiency drives innovation. The CNC turning center is pivotal in meeting these needs. According to a recent report from the International Federation of Robotics, the CNC machine tool market is forecasted to grow by over 7% annually through 2026. This growth indicates increasing reliance on advanced manufacturing technologies.

CNC turning centers offer unmatched advantages. They enable high-speed machining and tight tolerances, making them invaluable in industries like aerospace and automotive. However, navigating the complexities of features can be challenging. Not every turning center meets specific production requirements, which reveals the need for careful evaluation.

Investing in the right CNC turning center requires understanding features and potential limitations. Current data shows that nearly 30% of manufacturers struggle to optimize their CNC equipment fully. As this trend persists, businesses must adapt and innovate. Embracing advanced features can transform production processes, but it's essential to ensure they align with operational goals.

Key Features of 2026 CNC Turning Centers

CNC turning centers are essential for precision machining. In 2026, these machines offer advanced features that enhance productivity and accuracy. Key features include automated tool changers, which streamline operations. This reduces downtime and increases output.

Another significant feature is live tooling. Live tooling allows for milling and drilling while the part is being turned. This versatility saves time and adds complexity to machined parts. Remember, however, that the setup can be complex. Proper training is crucial for operators to fully utilize this capability.

Tips: Regular maintenance is vital to avoid unexpected breakdowns. Always check alignment and calibration before starting a new job. Additionally, consider investing in software upgrades. They can improve efficiency and enhance machine capabilities over time.

Another important aspect is the control interface. An intuitive interface simplifies programming and operation. New operators may struggle with complex systems. Therefore, ease of use should be a priority when selecting a CNC turning center. Keeping the technology user-friendly benefits everyone.

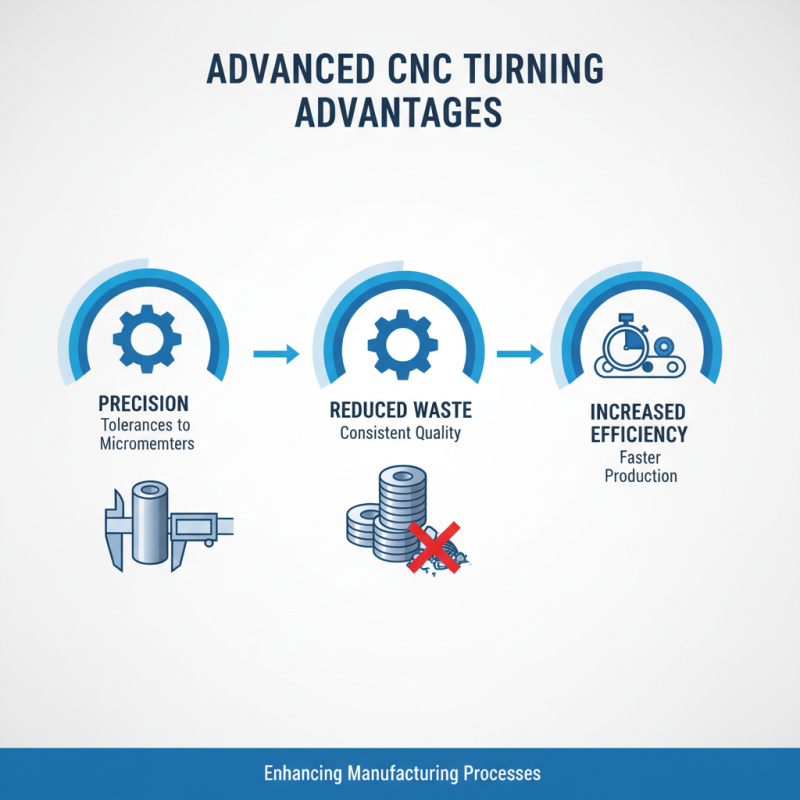

Advantages of Advanced CNC Turning Technology

Advanced CNC turning technology offers numerous advantages that can significantly enhance manufacturing processes. One major benefit is precision. Modern CNC turning centers can achieve tolerances as tight as a few micrometers, ensuring consistent quality in every part produced. This level of accuracy reduces waste and increases efficiency, crucial in today’s competitive market.

Another key advantage is automation. Advanced CNC machines can operate continuously, minimizing downtime. Operators can program complex designs in a fraction of the time it would take for manual machining. This reduces labor costs and allows skilled workers to focus on more critical tasks. However, while automation is beneficial, it may lead to over-reliance on technology.

Flexibility is another feature worth noting. CNC turning centers can quickly switch between different production runs. This adaptability is essential for businesses facing fluctuating demand. However, it’s important to remember that with flexibility comes a learning curve. Operators must be adequately trained to adjust settings and troubleshoot issues promptly. Balancing these challenges with the benefits of advanced CNC technology is key for successful operations.

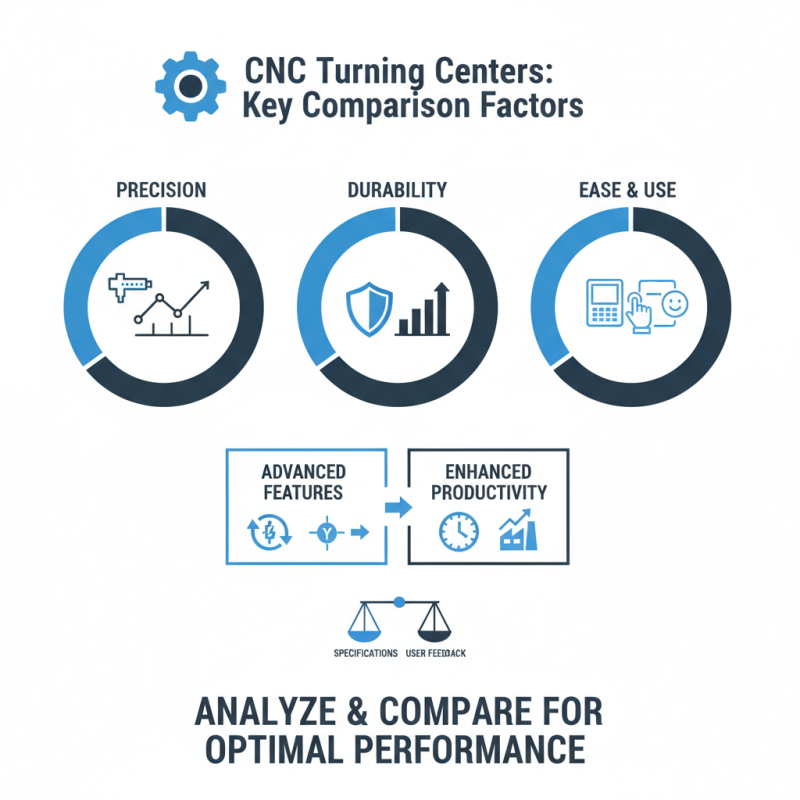

Comparison of CNC Turning Centers by Leading Brands

When comparing CNC turning centers, factors like precision, durability, and ease of use matter greatly. Many models offer advanced features like live tooling and Y-axis capability. This can greatly enhance productivity. However, not all machines maintain the same performance level. It's crucial to analyze specifications and user feedback closely.

Different brands emphasize various attributes. Some machines excel in speed, while others focus on intricate detail. Buyers should consider their specific needs. Is speed more vital than versatility? Often, trade-offs exist. A center that excels in one area may fall short in another.

Additionally, the support and training offered can make a difference. Some manufacturers provide extensive resources, while others leave users to rely on manuals. It's essential to evaluate these aspects. Investing in a CNC turning center requires careful thought. The right choice should align with both operational goals and budget constraints.

Applications and Industries Benefiting from CNC Turning

CNC turning centers are revolutionizing various industries. These machines excel in precise and efficient production processes. They are a vital part of manufacturing settings like automotive, aerospace, and electronics. The versatility of CNC turning centers allows for the creation of complex parts with high accuracy.

The automotive industry benefits greatly from CNC turning. Components like engine parts, shafts, and hubs can be machined to exact specifications. The aerospace sector also relies on these machines for lightweight and durable components. Some parts must meet strict tolerance levels, which can be challenging. Yet, CNC technology can address this need effectively.

Beyond traditional industries, medical applications are emerging. Customized implants and surgical tools require precision that CNC turning centers offer. However, frequent machine maintenance can pose challenges. Companies must invest time in training and upkeep. This aspect often gets overlooked, yet it is crucial for smooth operations. Embracing CNC technology should also include an understanding of these challenges.

2026 Best CNC Turning Center Features and Benefits

The chart above illustrates the key features and benefits of the best CNC turning centers for 2026. Each benefit is rated on a scale of 1 to 10, providing insights into precision, speed, flexibility, automation, and cost efficiency, which are crucial for various applications across industries.

Future Trends in CNC Turning Center Development

Future trends in CNC turning center development indicate an exciting evolution in machining technology. Automation is leading this change. Machines are now equipped with advanced sensors. These sensors enable real-time monitoring, improving accuracy. Operators can receive instant data, paving the way for smarter decision-making.

Sustainable practices are also becoming crucial. More manufacturers are aiming to reduce waste and energy consumption. This pushes the development of eco-friendly materials and processes. Affordability remains a challenge. Not every shop can adopt the latest technology immediately. There is a learning curve, and investment is needed. Balancing innovation with accessibility will be key.

User-friendliness is gaining importance. As skilled labor becomes scarcer, machines must cater to a broader audience. Simplified interfaces and intuitive controls are essential. Training programs will need to evolve. This adaptation is necessary to maintain efficiency. The future is indeed bright, yet it requires ongoing adaptation and reflection.

Related Posts

-

Ultimate Guide to CNC Turning Machine Benefits and Applications for Beginners

-

2025 How to Choose the Best CNC Turning Center for Your Manufacturing Needs

-

How to Choose the Right CNC Turning Center for Your Machining Needs

-

Top 10 CNC Turning Center Benefits Your Business Should Know?

-

Exploring the Future of Precision Engineering with CNC Turning Machines

-

Discover the Best Techniques for CNC Turning Parts Manufacturing Efficiency