Discover the Best Techniques for CNC Turning Parts Manufacturing Efficiency

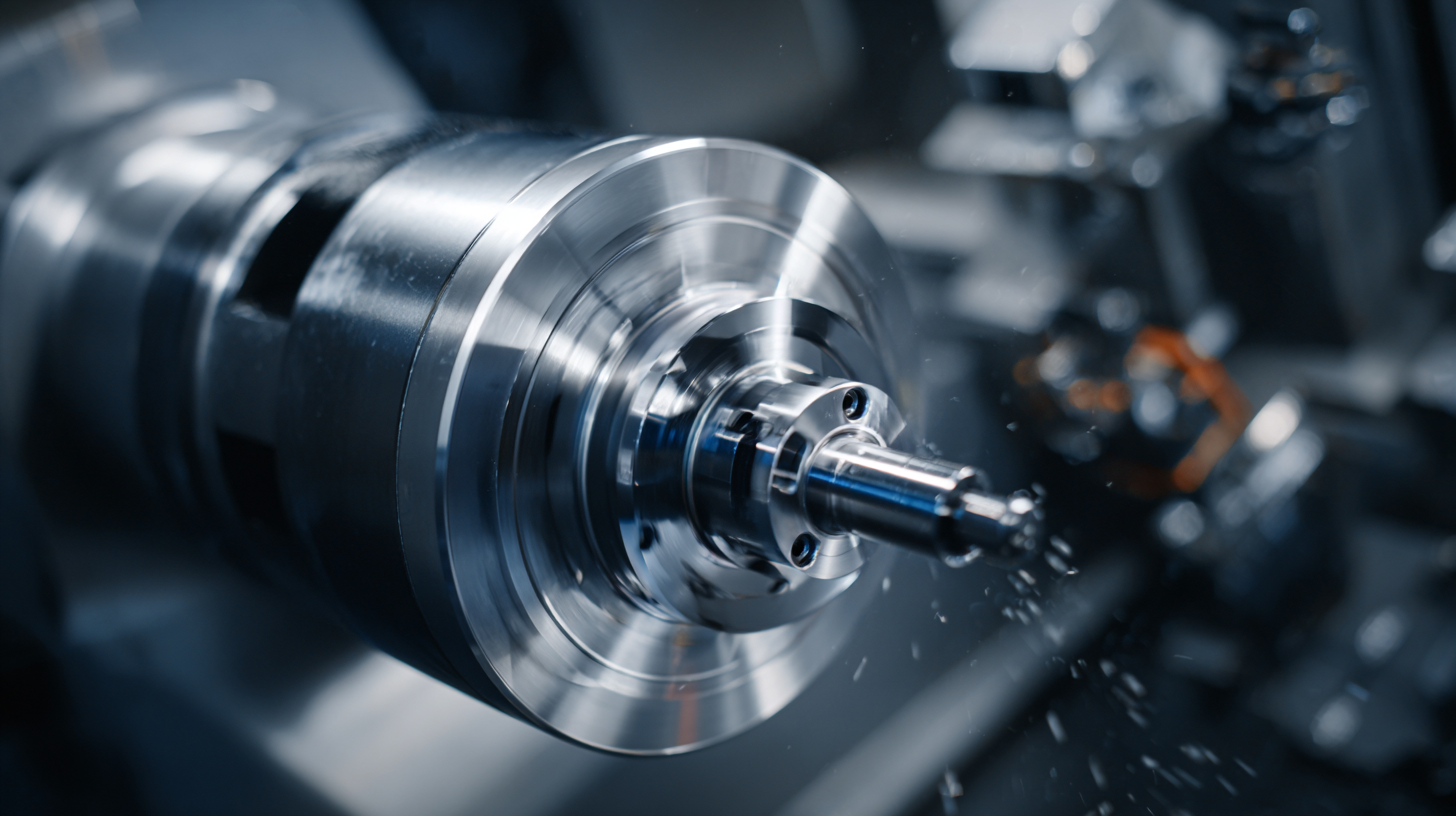

In the ever-evolving landscape of manufacturing, enhancing efficiency in CNC turning parts production has become paramount for industry leaders. According to a recent report by MarketsandMarkets, the CNC machining market is projected to reach $100 billion by 2025, driven largely by increasing demand for precision components in various sectors, including aerospace and automotive. As companies strive to meet these demands while reducing lead times and costs, leveraging advanced techniques in CNC turning parts manufacturing is essential. Innovations such as automated tool changes and adaptive machining not only streamline operations but also significantly improve product quality. This article aims to explore the best practices and latest advancements that can help manufacturers optimize their CNC turning parts processes, ultimately leading to higher productivity and competitiveness in the market.

In the ever-evolving landscape of manufacturing, enhancing efficiency in CNC turning parts production has become paramount for industry leaders. According to a recent report by MarketsandMarkets, the CNC machining market is projected to reach $100 billion by 2025, driven largely by increasing demand for precision components in various sectors, including aerospace and automotive. As companies strive to meet these demands while reducing lead times and costs, leveraging advanced techniques in CNC turning parts manufacturing is essential. Innovations such as automated tool changes and adaptive machining not only streamline operations but also significantly improve product quality. This article aims to explore the best practices and latest advancements that can help manufacturers optimize their CNC turning parts processes, ultimately leading to higher productivity and competitiveness in the market.

How to Optimize CNC Turning Processes for Maximum Production Speed

To optimize CNC turning processes for maximum production speed, it's essential to focus on several key techniques. First, selecting the right tooling can significantly improve efficiency. High-performance cutting tools made from materials such as carbide or ceramics offer greater durability and allow for faster cutting speeds. Utilizing appropriate tool geometries that suit the specific materials being machined enhances chip removal and reduces cycle times.

In addition to tooling, programming plays a crucial role in streamlining CNC turning operations. Implementing advanced CAD/CAM software can help in generating optimized tool paths that minimize unnecessary movements and ensure smoother transitions during machining. Furthermore, employing strategies such as adaptive machining technologies can enable the CNC machine to automatically adjust its parameters based on real-time data, enhancing both speed and precision in production. By concentrating on these essential techniques, manufacturers can significantly enhance their CNC turning efficiency, leading to increased output and reduced manufacturing costs.

How to Select the Right Materials for Efficient CNC Turning Parts Manufacturing

When it comes to CNC turning parts manufacturing, selecting the right materials is crucial for optimizing efficiency and performance. Different materials offer varying properties such as strength, machinability, and resistance to wear, all of which impact the overall manufacturing process. For instance, aluminum and brass are popular choices due to their good machinability and reduced tooling wear, enabling faster production cycles.

**Tips:** To improve the efficiency of CNC turning parts manufacturing, consider materials that align with your project's specifics. For high-strength applications, steel alloys may be appropriate, while composites or plastics can offer weight savings and corrosion resistance. Always evaluate the trade-offs between material cost and performance to ensure the best fit for your manufacturing needs.

Another important factor to consider is the consistency of the material properties. Inconsistent material can lead to unpredictable machining outcomes and increased scrap rates. Selecting suppliers with a proven track record of quality material can greatly enhance production efficiency.

**Tips:** Invest time in researching and establishing relationships with reliable suppliers. This not only ensures material quality but also creates opportunities for bulk sourcing, which can reduce costs and lead times significantly. Regularly review and update your material selection criteria based on evolving project demands and technological advancements.

Discover the Best Techniques for CNC Turning Parts Manufacturing Efficiency

| Material Type | Machinability Rating | Cost per Unit ($) | Common Applications |

|---|---|---|---|

| Aluminum 6061 | 90 | 3.50 | Aerospace, Automotive |

| Brass C360 | 80 | 2.80 | Electrical connectors, Plumbing |

| Stainless Steel 304 | 70 | 4.00 | Food processing, Medical Equipment |

| Steel A36 | 60 | 3.00 | Construction, Machinery |

| Plastic Nylon (PA) | 85 | 1.20 | Gears, Mechanical parts |

How to Implement Advanced Tooling for Enhanced CNC Turning Performance

The implementation of advanced tooling in CNC turning is essential for enhancing manufacturing performance and efficiency. According to industry reports, the global CNC machining market is projected to grow significantly, reaching approximately $100 billion by 2025, driven by increased automation and the adoption of smart manufacturing technologies. By investing in state-of-the-art tooling options, manufacturers can optimize their machining processes, leading to reduced cycle times and improved precision.

The implementation of advanced tooling in CNC turning is essential for enhancing manufacturing performance and efficiency. According to industry reports, the global CNC machining market is projected to grow significantly, reaching approximately $100 billion by 2025, driven by increased automation and the adoption of smart manufacturing technologies. By investing in state-of-the-art tooling options, manufacturers can optimize their machining processes, leading to reduced cycle times and improved precision.

Moreover, the integration of digital manufacturing technologies offers remarkable advantages. For instance, advanced tool materials such as ceramics and cermets demonstrate superior wear resistance and thermal stability, allowing for longer tooling life and enhanced productivity. This transition not only promotes efficiency but also responds to the growing demand for quality and consistency in CNC turned parts across various sectors, including aerospace, automotive, and healthcare, where improved patient outcomes are increasingly prioritized. As industries move towards digital transformation, leveraging these advanced tooling technologies is crucial for maintaining competitive advantages and achieving sustainable growth.

How to Utilize Automation to Streamline CNC Turning Operations

The automation of CNC turning operations is becoming increasingly essential as the global CNC machine market is projected to soar from $101.22 billion in 2025 to $195.59 billion by 2032, achieving a staggering CAGR of 9.9%. This growth underscores the industry's shift towards embracing advanced technologies that enhance efficiency. By 2026, the CNC machining sector alone is expected to reach a valuation of approximately $129 billion, emphasizing the significant demand for optimized production processes.

Utilizing automation in CNC turning not only streamlines operations but also reduces setup times and minimizes human error. For instance, the introduction of AI-powered solutions is revolutionizing the manufacturing landscape, enabling businesses to adopt smarter manufacturing methods. With advancements like zero-point workholding systems, setup processes can be drastically reduced, allowing for quicker transitions between tasks. Furthermore, the new generation of CNC lathes has become increasingly robot-ready, equipped with user-friendly programming and tooling that facilitate seamless automation integration in manufacturing workflows. Such innovations represent a crucial step toward achieving higher efficiency and productivity in CNC turning operations.

How to Analyze and Improve CNC Turning Part Design for Better Efficiency

When it comes to enhancing CNC turning part manufacturing efficiency, a crucial step lies in the analysis and improvement of part design. Industry reports reveal that optimizing designs can lead to reductions in production time by up to 30%. This is often achieved by simplifying geometries, minimizing the number of setups, and focusing on uniform wall thicknesses. Embracing design for manufacturability (DFM) principles ensures that parts are not only easier to produce but also equip manufacturers with the capability to maintain tighter tolerances.

**Tips:**

1. Regularly review and update design specifications based on manufacturing capabilities and technology advancements.

2. Utilize software for simulation and analysis to identify potential bottlenecks before production begins.

Incorporating feedback from machinists during the design phase can further drive improvements. Studies indicate that involving frontline staff in the design process can result in an increase in efficiency by roughly 20%. By refining CNC turning part designs with these collaborative insights, companies can achieve not only cost savings but also improved quality and reduced waste in their production processes.

**Tips:**

1. Host workshops or brainstorming sessions with technical teams to foster innovative design solutions.

2. Analyze historical production data to pinpoint design aspects that frequently lead to delays or quality issues.