How to Choose the Right CNC Machine for Your Business Needs

Choosing the right CNC machine for your business needs can be a daunting task. With a variety of models and features available, it’s crucial to understand not only the capabilities of these machines but also how they align with your specific operational requirements. According to industry expert John Doe, a renowned figure in the CNC machining field, “The right CNC machine can significantly enhance your production efficiency and overall business growth.” This statement underscores the importance of making an informed decision when investing in such technology.

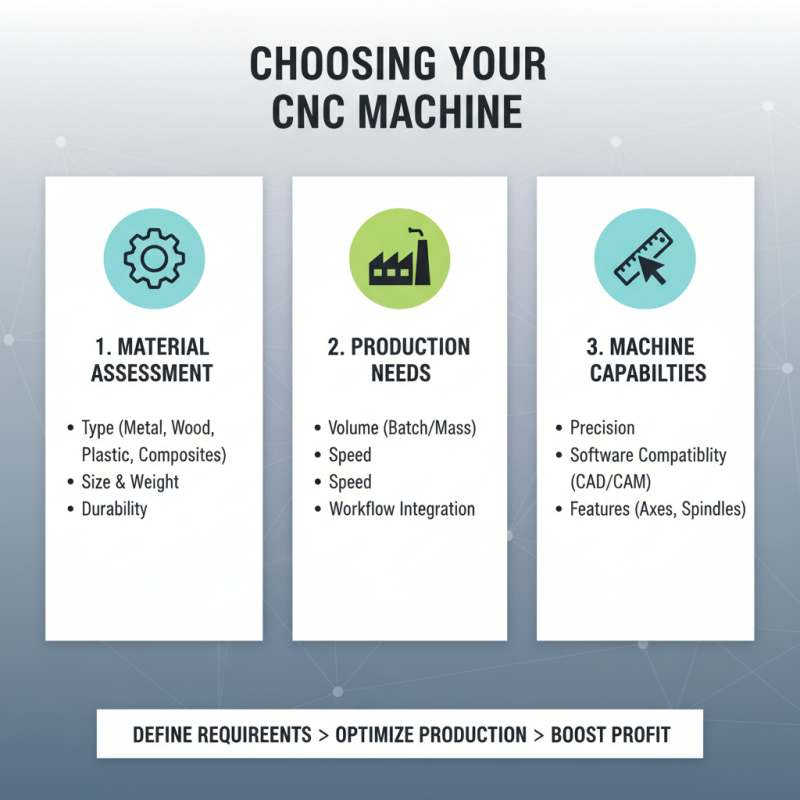

When evaluating which CNC machine best suits your needs, consider factors such as the type of materials you will be working with, the size and complexity of your projects, and your budget constraints. Whether your business is focused on prototyping, small-scale production, or high-volume runs, selecting the appropriate CNC machine can transform your workflow and boost productivity. By thoroughly assessing your requirements and obtaining reliable insights, you can identify the CNC machine that not only meets your current needs but also adapts to future demands in an evolving marketplace.

Understanding Your Business Requirements for CNC Machines

When choosing the right CNC machine for your business, it's crucial to have a clear understanding of your specific requirements. Begin by assessing the types of materials you’ll be working with, as this will influence the machine's capabilities. Consider factors such as size, weight, and durability of the materials, as well as the volume of production needed. A thorough evaluation of your business processes will help identify which features are essential, such as the machine's precision levels, speed, and the required software compatibility.

**Tips:** Analyze your current and future production needs to avoid purchasing a machine that may not scale with your business growth. It's advised to consult with experienced operators or industry experts to clarify any technical jargon and gain insights into the advantages and limitations of various CNC types.

Additionally, consider the operational environment where the machine will be placed. Factors such as space constraints, power supply, and maintenance access can significantly affect your choice. Always ensure you have the right support infrastructure in place—this includes not just the physical space but also trained personnel who can operate and maintain the machinery efficiently.

**Tips:** Invest time in training your staff properly to ensure they can maximize the machine's output. Engage in continuous learning about advancements in CNC technology, as this could open up new opportunities for enhancing your production processes.

Types of CNC Machines and Their Applications

When selecting a CNC machine, understanding the various types and their applications is crucial for making an informed decision. CNC milling machines are widely utilized in industries for tasks such as cutting, drilling, and shaping materials. These machines excel in creating complex parts and can handle a variety of materials, including metals and plastics, making them ideal for prototyping and high-volume production.

Another common type is the CNC lathe, which is perfect for producing cylindrical parts through rotational cutting. Lathes are particularly valuable in industries that require precision components, such as automotive and aerospace. Furthermore, CNC plasma and laser cutters are increasingly popular for their ability to slice through materials with high accuracy. These machines are particularly effective for sheet metal fabrication, allowing businesses to create intricate designs while minimizing waste.

Each type of CNC machine serves a unique purpose and offers distinct advantages, so businesses must consider their specific needs, materials, and production goals when choosing the right equipment. By aligning the type of CNC machine with their operational objectives, companies can enhance efficiency and improve the quality of their products.

Key Features to Consider When Selecting a CNC Machine

When selecting a CNC machine for your business, it’s essential to evaluate several key features that align with your production needs. First, consider the type of materials you will be working with. Different CNC machines are designed to handle specific materials, such as wood, metal, or plastics. Ensuring that the machine you choose is compatible with your desired substrates will enhance efficiency and reduce the likelihood of damage. Additionally, assess the machine's cutting capabilities, including the maximum speed and precision. Higher cutting speeds can translate to increased productivity, while precision is crucial for ensuring that your finished products meet stringent quality standards.

Another critical feature to examine is the machine’s workspace or bed size. The dimensions of your CNC machine should accommodate the largest parts you intend to manufacture. A larger workspace allows for the production of bigger components without the need for multiple setups, thereby saving time and improving workflow. Furthermore, explore the software compatibility of the CNC machine. An intuitive operating system with robust features can streamline the programming process and enhance productivity. Ultimately, a thorough understanding of these key characteristics will empower you to make an informed decision that best fits the unique needs of your business.

Budgeting and Cost Considerations for CNC Machines

When choosing the right CNC machine, budgeting and cost considerations play a critical role in the decision-making process. According to a recent report by the International Federation of Robotics, the global CNC machine market is expected to grow at a CAGR of 7.2% over the next five years, indicating a strong demand for automation in various industries. This surge in demand highlights the importance of making informed financial decisions when investing in CNC technology, as the initial purchase price can vary significantly based on machine type, complexity, and included features.

In general, entry-level CNC machines can start from around $5,000, while high-end models equipped with advanced capabilities may exceed $100,000. Businesses must consider not only the purchase price but also ongoing operating costs such as maintenance, tooling, software licenses, and training for personnel. A study from the Manufacturing Technology Association reveals that operational costs can account for up to 70% of a CNC machine's total cost over its lifespan, underscoring the need for a comprehensive budgeting approach that encompasses both initial spend and long-term operational expenditures. By carefully weighing these factors, companies can identify a CNC solution that aligns with their financial constraints and production goals, ultimately maximizing their return on investment.

Assessing Support and Training Options from Suppliers

When selecting the right CNC machine for your business needs, one critical factor to consider is the support and training options provided by suppliers. According to a 2022 report by the Association for Manufacturing Technology (AMT), nearly 65% of manufacturers indicated that inadequate training significantly affected the productivity and operational efficiency of their CNC machines. This statistic underscores the necessity of comprehensive training programs that equip your workforce with vital skills to operate and maintain the machinery effectively.

Moreover, the availability of ongoing support is equally important. A recent survey by the National Institute of Standards and Technology (NIST) found that companies with strong supplier support experienced a 30% decrease in downtime. Access to resources such as troubleshooting guides, on-site assistance, and online training modules can dramatically enhance your team's ability to respond to machine malfunctions. When evaluating suppliers, prioritize those who offer robust support and training, as this can ultimately lead to better performance and increased ROI for your CNC investment.

How to Choose the Right CNC Machine for Your Business Needs - Assessing Support and Training Options from Suppliers

| Machine Type | Support Offered | Training Options | Warranty Period | Technical Support Availability |

|---|---|---|---|---|

| Vertical CNC Milling Machine | 24/7 Online Support, On-site Assistance | In-person Training, Online Tutorials | 2 Years | Phone and Email Support |

| CNC Plasma Cutter | Live Chat Support, Remote Diagnostics | Webinars, Hands-on Workshops | 1 Year | Limited Hours Support |

| CNC Router | Email Support, Spare Parts Supply | Full-Day Training Sessions | 3 Years | 24/7 Phone Support |

| CNC Turning Center | In-person Technical Support, Help Desk | Self-paced E-learning | 2 Years | On-call Support |

Related Posts

-

Exploring the Future of Manufacturing: How CNC Machine Tools Revolutionize Precision Engineering

-

Discover the Best Techniques for CNC Turning Parts Manufacturing Efficiency

-

Unlocking Precision: How CNC Machining Parts are Revolutionizing Modern Manufacturing

-

Maximizing Efficiency and Precision in Manufacturing with CNC Lathe Technology Insights and Trends

-

2025 Top 10 CNC Machines: Unveiling the Future of Precision Engineering and Automation

-

Top 10 CNC Turning Parts Manufacturers for Precision Engineering Solutions