How to Choose the Right CNC Parts for Your Machining Projects

Choosing the right CNC parts for your machining projects is essential for achieving precision, efficiency, and productivity in manufacturing. As industry expert John Smith, a renowned CNC machining consultant, aptly puts it, "The quality of CNC parts can make or break your project; every detail counts towards the final output." With a plethora of options available, understanding the key factors that influence your selection process is crucial for both novice and experienced machinists alike.

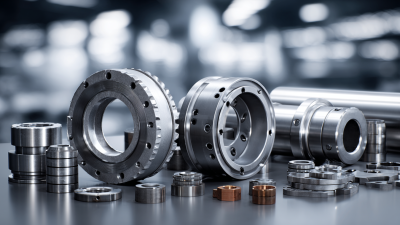

When selecting CNC parts, one must consider aspects such as material compatibility, durability, and design specifications. Different projects may require varying levels of precision, which directly affects the choice of components. Moreover, recognizing the distinct characteristics of various CNC parts can lead to informed decisions that enhance overall performance and reduce production downtime. By prioritizing quality and suitability, machinists can streamline their operations and ensure that their projects meet the highest industry standards.

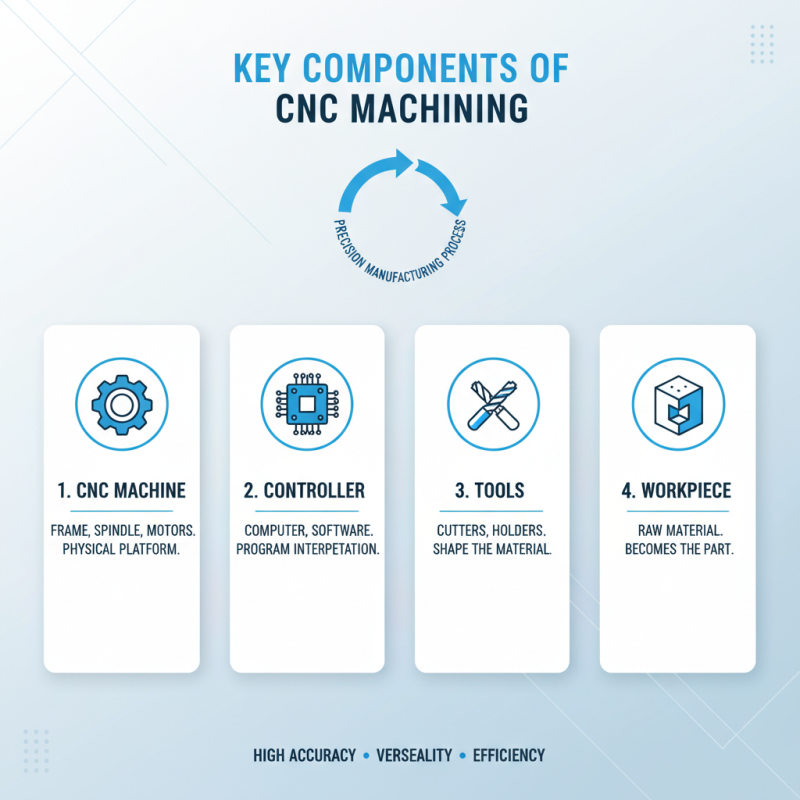

Understanding CNC Machining and Its Components

CNC machining is a highly precise manufacturing process that utilizes computer-controlled machinery to create parts and components across various industries. Understanding the key components of CNC machining is essential for selecting the right parts for your projects. The main components include the CNC machine itself, the controller, tools, and the workpiece. Each part plays a crucial role in ensuring the efficiency and accuracy of the machining process.

The CNC machine serves as the foundation, featuring moving parts like the spindle, axes, and worktable. The controller is the brain of the system, which interprets the design files and directs the machine’s movements. Selecting the right cutting tools is equally important, as they determine the quality of the finished product and the types of materials that can be processed. The workpiece, which is the material being machined, needs to be compatible with the chosen tools and machine to achieve the desired results. By understanding these components and their functions, you can make informed decisions about the CNC parts that best suit your specific machining requirements.

Identifying the Key Factors in CNC Parts Selection

When selecting CNC parts for machining projects, it's crucial to identify key factors that will ensure optimal performance and compatibility with your specific requirements. One of the primary considerations is the material of the CNC parts. Different materials offer varying strengths, thermal resistance, and machining characteristics. Understanding the operating conditions and loads your parts will encounter can help you choose the best material, whether it be aluminum for lightweight applications or steel for high-strength requirements.

Another vital factor is the precision and tolerance levels required for your project. CNC machining allows for high precision, but each part must be designed with specific tolerances in mind. Assessing the functional needs of your project will help determine the necessary tolerances, whether they are stringent for intricate designs or more lenient for larger components. Additionally, the geometry and design of the parts play a significant role in manufacturability. Ensuring that your CNC parts are designed for effective machining will not only improve production efficiency but also lead to better overall quality in the final product. By focusing on these key elements, you can make informed decisions that align with your machining objectives.

Key Factors in CNC Parts Selection

Evaluating Material Compatibility for CNC Machining Projects

When undertaking CNC machining projects, evaluating material compatibility is crucial for achieving optimal results. Different materials have distinct properties that affect machinability, strength, durability, and finishing. Aluminum, steel, plastics, and composites each require specific tools and techniques to work effectively. Understanding the mechanical properties of these materials will help you choose the right CNC parts and ensure seamless interactions during the machining process.

**Tips:** Always review the material specifications and select CNC parts that match the physical and chemical properties of your chosen material. For example, softer materials like plastics may require less robust tools, whereas harder metals necessitate specialized tooling for effective machining. Conducting tests on a small scale can also provide valuable insights into how material acts under machining conditions.

Another consideration is the compatibility of thermal properties. Materials respond differently to heat generated during CNC operations, which can lead to warping or changes in structural integrity. Selecting CNC parts designed to mitigate these effects will enhance overall performance.

**Tips:** Invest in cooling systems or lubrication strategies that complement your chosen material. This will not only extend the life of your CNC parts but improve the precision of your machining projects as well. Always keep in mind that the right combination of material and CNC parts can significantly enhance the outcome of your projects.

How to Choose the Right CNC Parts for Your Machining Projects - Evaluating Material Compatibility for CNC Machining Projects

| Material | CNC Machining Compatibility | Ideal Applications | Strengths | Considerations |

|---|---|---|---|---|

| Aluminum | Excellent | Aerospace, Automotive parts | Lightweight, Corrosion resistant | Thermal expansion and machining speed |

| Steel | Good | Construction, Tooling | High strength, Versatility | Weight and potential for rust |

| Titanium | Moderate | Medical, Aerospace | High strength-to-weight ratio, Corrosion resistance | Expensive, Difficult to machine |

| Copper | Excellent | Electrical components, Plumbing | Excellent conductivity, Ductility | Softness, Not very strong |

| Plastic (ABS) | Good | Consumer products, Prototyping | Lightweight, Cost-effective | Lower heat resistance |

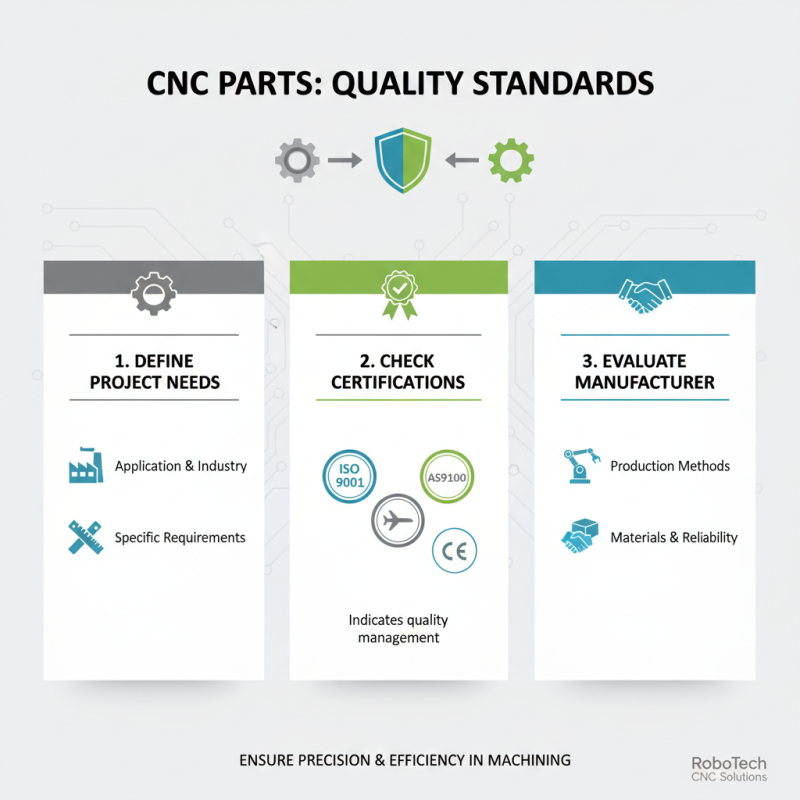

Assessing Quality Standards for CNC Components

When selecting CNC parts for your machining projects, assessing the quality standards of components is crucial to ensure efficiency and precision. Quality standards often vary by application and industry, making it essential to first understand the specific requirements of your project. Look for certifications such as ISO, AS9100, or similar quality management and manufacturing standards that indicate a commitment to excellence. These certifications often reflect the manufacturer’s production methods, materials used, and overall reliability of their CNC components.

In addition to certifications, consider the materials and manufacturing processes involved in the production of CNC parts. The use of high-grade materials not only contributes to the durability and longevity of parts but also impacts performance under various machining conditions. Investigating the tolerances and dimensional accuracy specified by the manufacturer can provide insight into how well the components will function in your specific environment. Always prioritize suppliers that offer transparency about their testing and quality assurance processes, as this can significantly influence the outcome of your machining projects.

Considerations for Budgeting and Sourcing CNC Parts

When budgeting for CNC parts, it’s essential to have a clear understanding of your project's specific requirements. Start by outlining the essential components needed for your machining task, considering the materials you’ll be working with and the precision required. Creating a detailed list allows you to estimate costs more accurately, making it easier to identify areas where you can allocate funds efficiently. Keep in mind that while it may be tempting to cut costs on components, investing in quality parts can significantly affect the overall performance and longevity of your machinery.

Sourcing CNC parts requires thorough research to find suppliers who offer reliable products without compromising your budget. Reach out to multiple vendors to compare prices, but also consider their reputation, customer service, and delivery times. It might be worthwhile to explore both local and international suppliers, as this can affect not only cost but also logistics and lead times. Additionally, check if suppliers have a track record of providing parts that meet industry standards. Balancing price with quality and reliability will ensure that your final machining projects are successful and cost-effective.

Related Posts

-

Exploring the Future of Precision Engineering with CNC Turning Machines

-

Unlocking Innovation: The Vital Role of Machined Parts in Modern Manufacturing Advances

-

Unlocking Precision: How CNC Machining Parts are Revolutionizing Modern Manufacturing

-

Top 10 Benefits of Using Prototype Machined Parts for Your Projects

-

Top Benefits of Using Machined Parts in Modern Manufacturing Processes

-

Exploring the Future of Manufacturing: How CNC Machine Tools Revolutionize Precision Engineering