How to Choose the Right Milling Machine Tools for Your Project

Choosing the right milling machine tools is crucial for project success. In the manufacturing industry, precision is key. According to a 2021 report by Grand View Research, the global milling machine market is expected to reach $8.04 billion by 2028. This highlights the growing demand for efficient tools.

Milling machine tools play a vital role in various applications, from automotive to aerospace. Proper selection can enhance productivity and reduce waste. However, many users often overlook critical factors like material compatibility and tool geometry. A wrong choice can lead to costly downtime and subpar results.

Investing time in research is essential. Many manufacturers offer a variety of milling machine tools, each suited for different tasks. An informed decision can make a significant difference. It's important to reflect on past experiences and consider how they shaped tool selections. In this dynamic industry, adapting to changes is necessary for success.

Understanding Milling Machine Types: Horizontal vs. Vertical Usage

Choosing the right milling machine type can drastically influence your project outcomes. Two prominent types are horizontal and vertical milling machines. Each has its unique benefits, yet their selection depends on the specific tasks at hand.

Vertical mills are known for their ease of use. You can approach your work from multiple angles without repositioning your workpiece.

Horizontal milling machines, on the other hand, excel at heavy and high-volume tasks. Their design allows for greater control over the cutting process, which is particularly useful for more complex tasks, but they can be tricky to set up. Many users find that transitioning from vertical to horizontal requires extra expertise.

It’s essential not to overlook the project requirements when making your choice. A common mistake is to choose based solely on the machine's capabilities. Sometimes, a simpler vertical mill will do the trick efficiently. Reflect on your specific needs and available resources. That way, you’ll select the right tool to achieve your project goals.

Key Factors in Selecting Milling Tool Materials: High-Speed Steel vs. Carbide

Selecting the right milling tool material is crucial for project outcomes. Two dominant choices are high-speed steel (HSS) and carbide. Each has distinct advantages and limitations. According to industry reports, HSS offers good flexibility and is less prone to chipping. However, it may wear out faster on tougher materials, leading to more frequent tool changes.

Conversely, carbide tools deliver superior hardness. They excel in high-speed applications and can withstand higher temperatures. A study indicates that carbide tools can last up to eight times longer than HSS in certain conditions. However, their brittleness makes them more susceptible to breakage during aggressive machining processes. This trade-off between durability and resilience is a key consideration in tool selection.

Furthermore, cost can be a determining factor. HSS is generally more affordable, making it attractive for smaller projects. Yet, the long-term savings from using carbide can offset initial costs. It's essential to evaluate the specific requirements of your project. An ill-chosen tool can lead to inefficiencies and quality issues. Balancing performance, cost, and project demands is an ongoing challenge for manufacturers.

Comparison of Milling Tool Materials: High-Speed Steel vs. Carbide

Assessing Project Requirements: Size, Complexity, and Precision Needs

Choosing the right milling machine tools hinges on assessing project requirements like size, complexity, and precision needs. Projects vary widely in dimensions and demands, often influencing tool selection. For example, a study by The Metalworking Industry Association reported that nearly 70% of manufacturers struggle with precision in smaller projects.

Complexity plays a vital role too. The same research found that projects requiring complex geometries might necessitate advanced tooling systems. These systems can add time and cost, with reports showing precision milling tools can be 30% more expensive than basic options. This difference can strain budgets if not planned properly.

Precision is essential in industries like aerospace and automotive, where tolerances can be as tight as ±0.005 inches. Yet, many companies find it challenging to meet these specifications consistently. A reflection on past projects can reveal gaps in tooling choices. As technology advances, so does the need to reevaluate equipment. Choosing the wrong tools can lead to costly errors, making it crucial to analyze project specifics with rigorous detail.

Analyzing Cutting Speed and Feed Rate: Industry Best Practices

When selecting milling machine tools, cutting speed and feed rate are crucial factors. The cutting speed refers to how fast the cutting tool moves relative to the workpiece. It significantly impacts the quality and efficiency of the machining process. A higher cutting speed can lead to quicker results but may cause overheating or tool wear. It's essential to find a balance that suits your material type and desired finish.

The feed rate is the distance the tool advances during each rotation. This rate influences chip thickness, surface finish, and tool life. If the feed rate is too high, it can lead to rough surfaces or tool failure. Yet, if it’s too low, production time increases unnecessarily. Monitoring these two elements requires careful thought and sometimes trial and error.

It's easy to overlook these factors. Beginners often rush or rely on instinct rather than data. A better approach involves measuring outcomes and adjusting parameters. Analyze results continuously. Reflecting on past projects can provide insight into improving efficiency and quality. Each decision shapes the overall success of your machining tasks.

How to Choose the Right Milling Machine Tools for Your Project

| Tool Type | Cutting Speed (RPM) | Feed Rate (IPM) | Material Compatibility | Ideal Application |

|---|---|---|---|---|

| End Mill | 1500 - 4000 | 5 - 20 | Aluminum, Steel, Plastics | General Milling and Contouring |

| Ball Nose Cutter | 1200 - 3500 | 4 - 15 | Wood, Plastics, Soft Metals | 3D Contouring and Surface Finish |

| Face Mill | 1000 - 3000 | 8 - 25 | Steel, Cast Iron | Flat Surface Machining |

| Slot Drill | 1400 - 3600 | 5 - 18 | Aluminum, Mild Steel | Keyways and Slots |

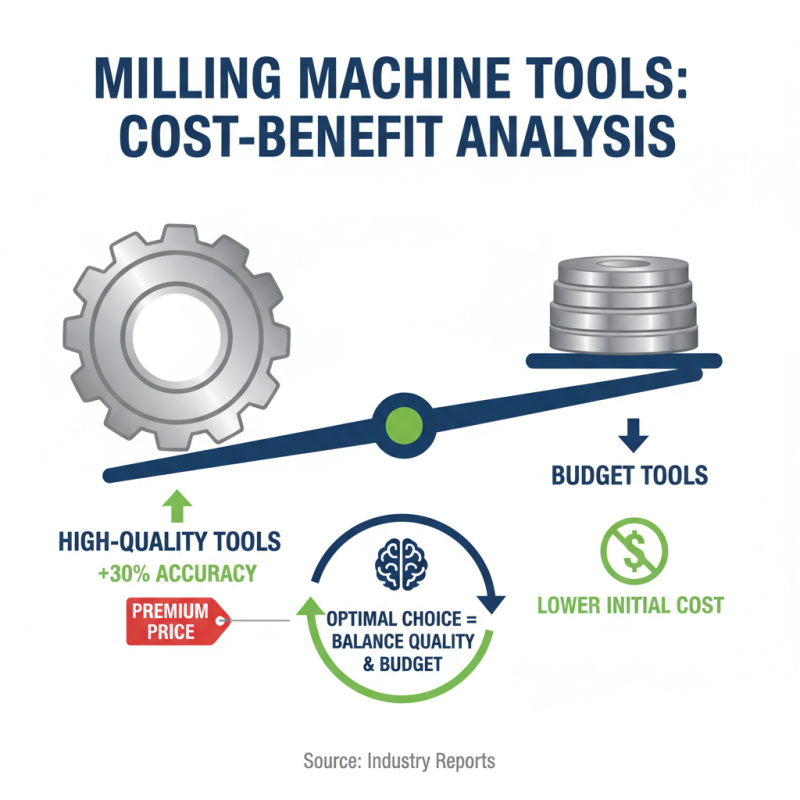

Cost-Benefit Analysis: Balancing Quality and Budget in Tool Selection

When selecting milling machine tools, balancing quality and budget is crucial. A good cost-benefit analysis can help. Reports suggest that high-quality tools can enhance accuracy by 30%. However, they often come with a premium price.

Consider your project requirements. Are you working with metals or softer materials? Softer materials may require less expensive tools. A recent study showed that using budget tools for simple tasks saves 15% on overall costs. But be careful; cheaper tools may wear out quickly, leading to more frequent replacements.

Tips: Look for tools with good warranties. This can mitigate risk. Spending more on durable tools may yield long-term savings. Examine tool life data before making purchases. Sometimes, investing upfront pays off faster than expected. Quality makes a difference but must align with budget constraints.

Related Posts

-

2025 Guide: How to Choose the Best Milling Machine Tools for Your Workshop

-

How to Choose the Right CNC Parts for Your Machining Projects

-

Top 10 CNC Milling Machines for Precision Machining in 2023

-

How to Choose the Best CNC Machining Prototyping Techniques for Your Project

-

Understanding the Benefits of Large Part CNC Machining for Precision Manufacturing

-

Unlocking Innovation: The Vital Role of Machined Parts in Modern Manufacturing Advances