Why Choosing the Right CNC Parts is Essential for Your Machinery Performance

In today's competitive manufacturing landscape, the significance of selecting the right CNC parts cannot be overstated. With the global CNC machine market projected to reach $100 billion by 2025, as reported by various industry analysts, it becomes imperative for manufacturers to ensure that each component of their machinery is optimized for performance. The efficiency, accuracy, and longevity of CNC machinery are heavily influenced by the quality of its parts; subpar components can lead to increased downtime and higher operational costs, which can ultimately hinder productivity and profitability.

Recent studies indicate that nearly 30% of production downtime in manufacturing environments is attributed to equipment failure, much of which can be traced back to inadequate or incompatible CNC parts. This highlights the critical need for manufacturers to invest in high-quality components that not only meet their rigorous operational demands but also enhance the overall reliability of their machinery. By prioritizing the acquisition of superior CNC parts, businesses can significantly improve their workflow, reduce maintenance costs, and accelerate their return on investment.

As the industry continues to evolve, with advancements in technology paving the way for more sophisticated CNC applications, the role of component selection becomes even more vital. Stakeholders must remain vigilant in sourcing the right CNC parts to stay ahead of the competition and meet the ever-increasing demands for efficiency and precision in manufacturing processes.

Understanding the Role of CNC Parts in Machinery Performance

The components used in CNC (Computer Numerical Control) machinery play a pivotal role in determining overall performance and efficiency. Each part, from the spindle and servo motors to the control software, contributes to the precise functionality that defines CNC systems. The accuracy of machining operations relies heavily on the quality and compatibility of these parts; even minor discrepancies can lead to significant deviations in production outcomes. Furthermore, the integration of high-quality components can enhance the durability and longevity of the machinery, reducing the likelihood of breakdowns and costly downtimes.

Understanding the intricacies of CNC parts is essential for optimizing performance. For instance, the choice of cutting tools can influence not only the speed of operation but also the finish quality of the machined parts. Similarly, precision drivers and robust power supplies ensure that machinery operates within specified tolerances, improving both accuracy and repeatability. As industries increasingly demand higher precision and faster turnaround times, recognizing the critical role that CNC parts play will enable manufacturers to achieve their production goals effectively and efficiently.

Why Choosing the Right CNC Parts is Essential for Your Machinery Performance

| CNC Part Type | Material | Precision Level | Typical Applications | Impact on Performance |

|---|---|---|---|---|

| Spindle | Steel | High Precision | Milling, Drilling | Critical for Accuracy |

| Ball Screw | Alloy Steel | Medium Precision | Positioning | Influences Movement Speed |

| Tool Holder | Aluminum | Standard Precision | Machining | Affects Tool Change Time |

| Linear Guideway | Carbon Steel | High Precision | Automated Cutting | Determines Movement Smoothness |

| Control System | Electronic Components | High Precision | All CNC Machinery | Controls Overall Performance |

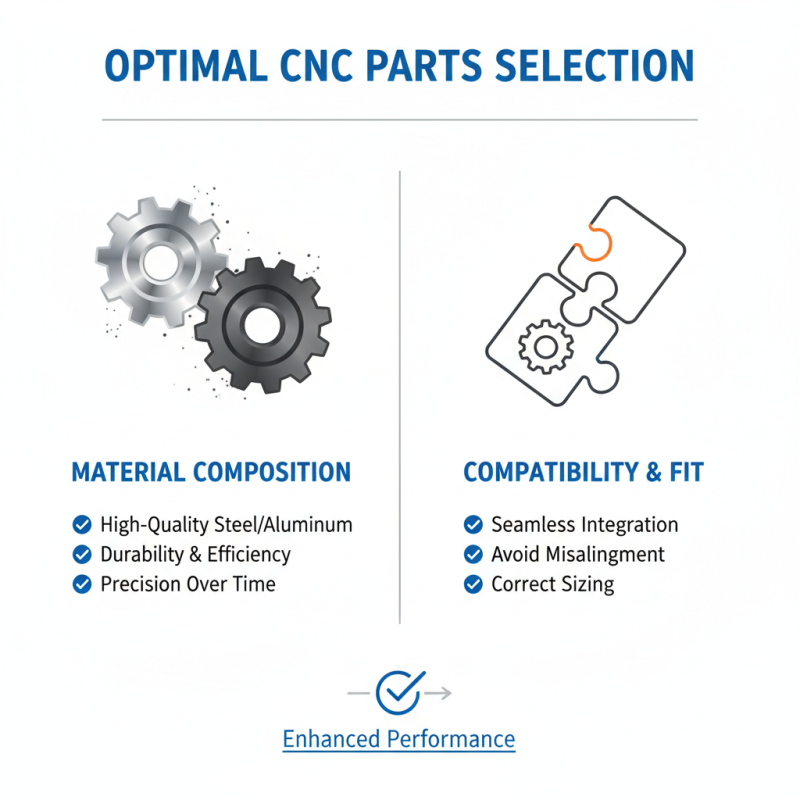

Key Factors to Consider When Selecting CNC Parts

When selecting CNC parts for your machinery, several key factors must be considered to ensure optimal performance. First and foremost, the material composition of the CNC parts plays a crucial role in their durability and efficiency. Parts made from high-quality materials such as steel or aluminum can withstand the stresses of machining while maintaining precision over time. Additionally, the compatibility of the CNC parts with your existing machinery cannot be overlooked; parts should be specifically designed to fit seamlessly to avoid issues that can arise from misalignment or incorrect sizing.

Another important factor is the level of customization available for CNC parts. Depending on the specific requirements of your projects, you may need parts that are tailored to perform specific functions or to operate under particular conditions. This customization might include adjustments in size, shape, or functionality. Furthermore, the reputation of the manufacturer and their commitment to quality assurance processes can significantly impact the reliability and performance of the components. Choosing parts from reputable sources ensures that you are investing in products that meet industry standards and can enhance the overall efficiency of your machinery.

The Impact of Quality CNC Parts on Operational Efficiency

The operational efficiency of CNC machinery is heavily influenced by the quality of its parts. A report from the Association for Manufacturing Technology (AMT) indicates that a mere 5% increase in the quality of machine components can result in up to a 15% increase in overall production efficiency. High-quality CNC parts not only ensure precision and accuracy in machining processes but also significantly enhance reliability and longevity. This minimizes downtime and maintenance costs, creating a more streamlined production environment.

Additionally, the economic impact of utilizing superior CNC parts cannot be overlooked. According to a study by the Manufacturing Institute, companies that invest in quality components experience a 20% reduction in scrap rates and up to a 25% increase in product quality, leading to improved customer satisfaction and retention. By prioritizing quality over cost in part selection, manufacturers can optimize their operations and ultimately drive profitability. Thus, investing in the right CNC parts is not merely a choice; it is a strategic decision that can substantially elevate a business’s operational performance.

Impact of CNC Parts Quality on Operational Efficiency

This chart highlights the correlation between the quality of CNC parts and the operational efficiency of machinery. As the quality of CNC parts increases, the operational efficiency also improves, leading to reduced downtime and higher productivity.

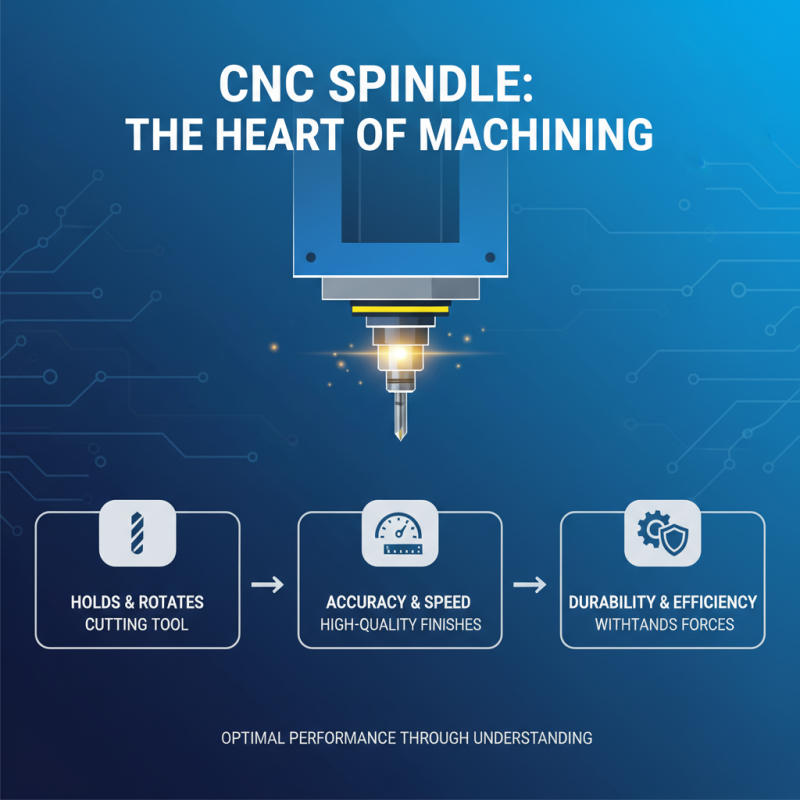

Common Types of CNC Parts and Their Functions

When selecting CNC parts for machinery, understanding the common types and their respective functions is crucial for optimal performance. One of the most fundamental components is the spindle, which holds and rotates the cutting tool. It directly influences the accuracy and speed of machining operations, making it essential for achieving high-quality finishes. The spindle's design and durability also play a significant role in the overall machining efficiency, as they must withstand various forces during operation.

Another vital part is the CNC control unit, which acts as the brain of the machinery. It interprets the CAD/CAM designs and translates them into precise movements. A high-quality control unit enhances synchronization and coordination among different machine parts, ensuring smooth operation. Additionally, the feed mechanisms are essential for moving the workpiece or tool into the correct position. These mechanisms can be linear or rotary, and their efficiency impacts the machining speed and precision significantly. Understanding the functions and types of these crucial CNC components can lead to informed choices that enhance equipment longevity and machining performance.

Maintenance Tips for Prolonging CNC Parts Lifespan

Proper maintenance of CNC parts is crucial to extending their lifespan and ensuring optimal machinery performance. One effective strategy is to implement a regular cleaning schedule. Dust, chips, and coolant residue can accumulate on machine parts, leading to rust and wear over time. Using appropriate cleaning solutions and tools, operators should wipe down surfaces regularly and ensure that any debris is removed, especially from critical areas such as rails, bearings, and spindles. Additionally, it is vital to periodically inspect these parts for any signs of wear or deterioration, allowing for early detection of potential issues.

Lubrication also plays a key role in prolonging the life of CNC components. Regularly applying the correct type and amount of lubricant helps reduce friction and wear, enhancing the functionality of moving parts. Operators should consult manufacturer recommendations on lubrication intervals and types, and keep detailed logs of maintenance activities. Furthermore, maintaining the right environmental conditions, such as controlling temperature and humidity, can significantly affect the longevity of CNC parts. By adhering to these maintenance tips, businesses can minimize downtime and repair costs while maximizing efficiency and productivity in their operations.

Related Posts

-

Top 10 CNC Milling Machines for Precision Machining in 2023

-

How to Choose the Right CNC Parts for Your Machining Projects

-

Exploring the Future of Manufacturing: How CNC Machine Tools Revolutionize Precision Engineering

-

Discover the Best Techniques for CNC Turning Parts Manufacturing Efficiency

-

Unlocking Precision: How CNC Machining Parts are Revolutionizing Modern Manufacturing

-

Maximizing Efficiency and Precision in Manufacturing with CNC Lathe Technology Insights and Trends