How to Choose the Right CNC Turning Center for Your Machining Needs

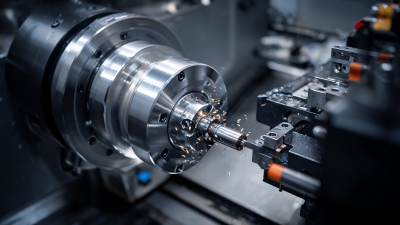

In the ever-evolving realm of precision machining, selecting the appropriate CNC turning center is crucial for optimizing production efficiency and product quality. As industry expert John Smith, a renowned CNC Machining Specialist, aptly states, "The right CNC turning center is not just a machine; it's an investment in precision and productivity that can significantly enhance your manufacturing capabilities." This sentiment resonates deeply within the manufacturing community, where the choice of machinery can profoundly affect operational success.

When evaluating CNC turning centers, it is essential to consider several factors, including the specific requirements of your projects, the materials you will be working with, and the desired level of automation. Understanding these elements allows manufacturers to select a turning center that aligns with their machining needs. The right CNC turning center not only improves efficiency but can also lead to innovations in design and production processes.

Ultimately, making an informed decision about a CNC turning center is critical for any machining operation aiming to stay competitive in today's market. By exploring the various options and understanding their capabilities, manufacturers can ensure they choose a machine that will deliver the best results for their specific applications.

Understanding Your Machining Requirements for CNC Turning Centers

Understanding your machining requirements is crucial when selecting the appropriate CNC turning center.

According to a report by Grand View Research, the global CNC machine market is projected to reach $100 billion by 2025, emphasizing the increasing reliance on precision engineering across numerous industries.

Identifying the specific needs for your projects—such as part complexity, material types, and production volume—will guide you toward a suitable CNC turning center.

For instance, if your operations primarily involve high-volume production of simple components, a high-speed, multi-axis CNC turning center may be the ideal choice.

On the other hand, for intricate parts requiring tight tolerances, a more advanced model with increased capabilities regarding tool exchange and cooling systems might be necessary.

A recent survey by the Automation Federation indicates that 70% of manufacturers reported improved efficiency after aligning their CNC equipment selection closely with their specific machining requirements.

Understanding these parameters not only enhances productivity but also maximizes return on investment in the long term.

Key Specifications to Consider in CNC Turning Centers

When selecting the right CNC turning center, it is crucial to focus on key specifications that align with your machining needs. One of the primary considerations is the size of the workpiece that the machine can accommodate. Understanding the maximum swing diameter and length of the component is essential to ensure that the turning center can handle your specific projects. Additionally, consider the machine’s chuck size and the stability gained from a larger chuck, which can enhance precision and reduce vibration during operation.

Another vital specification to evaluate is the spindle speed and power. A higher spindle speed allows for faster material removal rates, which can significantly improve productivity. Moreover, the power of the spindle affects the machine's ability to cut through various materials efficiently. It’s also important to assess the machine's tooling capability, such as the number of tool stations, which can impact versatility and overall efficiency in production. Opting for a CNC turning center with automatic tool changers can further streamline operations and reduce downtime when switching between different tasks.

Evaluating Control Systems and Software Options

When selecting a CNC turning center, the evaluation of control systems and software options is crucial for meeting specific machining needs. Modern CNC machines require sophisticated control systems that not only ensure precision but also enhance efficiency in production. A robust control system should offer intuitive interfaces, real-time monitoring capabilities, and flexible programming options to accommodate various machining tasks. Features such as error reporting and diagnostics can significantly streamline operations and reduce downtime.

Moreover, the software options available for CNC turning centers play a vital role in maximizing their capabilities. Users should consider software that supports advanced features like simulation, tool path optimization, and integration with existing enterprise resource planning (ERP) systems. Compatibility with various file formats and ease of use are essential for minimizing the learning curve for operators. By evaluating both control systems and software comprehensively, manufacturers can make informed decisions that align with their operational goals and improve overall productivity in their machining processes.

Budgeting and Cost Considerations for CNC Turning Centers

When considering the acquisition of a CNC turning center, budgeting and cost analysis are paramount. The market for CNC vertical machining centers is witnessing significant growth, with projections indicating an increase of approximately USD 1.09 billion by 2029, driven largely by the rising demand for CNC tools and advancements in artificial intelligence technologies. These factors suggest that investing in a CNC turning center can be a fruitful decision, provided one carefully assesses their financial capabilities and future operational needs.

Another crucial point is the cost of maintaining and operating CNC machinery. While the initial investment can be substantial, ongoing costs such as tooling, setup, and maintenance should be factored into the budget. Additionally, with the market's evolution towards AI-powered solutions, businesses must also consider the potential costs associated with integrating new technologies. By thoroughly evaluating these financial considerations, companies can make informed decisions that align with their growth strategy and operational capacity within the competitive machining landscape.

Assessing Brand Reputation and Support Services in CNC Machines

When selecting a CNC turning center, assessing brand reputation and support services is crucial for ensuring a seamless machining experience. A reputable brand often reflects years of innovation, reliability, and customer satisfaction. Before making a decision, research potential manufacturers and their market standing. Look for online reviews, case studies, and testimonials from other machinists to gauge how well each brand meets the needs of its users. A solid reputation often indicates not only quality machines but also adherence to safety standards and operational efficiency.

Equally important are the support services offered by these brands. A manufacturer that provides comprehensive after-sales support, including installation guidance, training, and ongoing customer service, can significantly enhance your operational capabilities. Determine if the brand offers readily available spare parts and technical assistance, as these factors can reduce downtime and improve productivity. By thoroughly evaluating both brand reputation and support services, you can select a CNC turning center that not only meets your machining needs but also ensures a reliable partnership for the long term.

Comparison of CNC Turning Center Features

Related Posts

-

2025 How to Choose the Best CNC Turning Center for Your Manufacturing Needs

-

Exploring the Future of Precision Engineering with CNC Turning Machines

-

2025 Top 10 CNC Machines: Unveiling the Future of Precision Engineering and Automation

-

Top 10 Benefits of Using Prototype Machined Parts for Your Project Success

-

Maximizing Efficiency and Precision in Manufacturing with CNC Lathe Technology Insights and Trends

-

The Future of Brass CNC Machining Innovations and Trends in Precision Engineering