Why is CNC Lathe Essential for Modern Manufacturing?

In today's fast-paced manufacturing landscape, the CNC lathe stands out as a cornerstone of efficiency and precision. As John Smith, a leading expert in CNC technology, once stated, "The CNC lathe transforms ideas into reality, driving innovation in manufacturing." This powerful tool not only enhances productivity but also allows for intricate designs that were once impossible.

With its ability to automate complex tasks, the CNC lathe minimizes human error and improves consistency. This means manufacturers can produce high-quality components at an unprecedented speed. Nevertheless, there are challenges to consider. For instance, the initial cost of a CNC lathe can be substantial. Companies must weigh this investment against potential returns. Moreover, training staff to operate this technology effectively is essential but often overlooked.

The versatility of a CNC lathe is remarkable. It can handle various materials, creating everything from simple parts to intricate designs. However, reliance on technology also invites scrutiny. Manufacturers must continually adapt to changes in the industry. Staying updated with the latest trends in CNC lathe technology is crucial. The balance between innovation and tradition remains a topic of discussion among professionals.

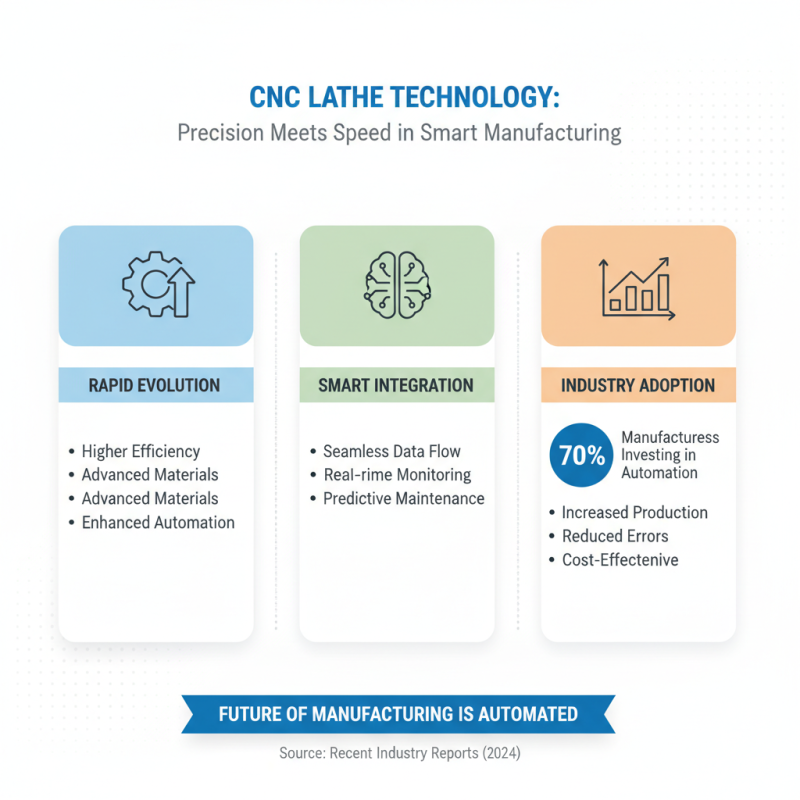

Evolution of CNC Lathe Technology in Manufacturing

CNC lathe technology has come a long way. In the past, manual lathes required significant skill and time. Operators used their hands to shape metal, often leading to inconsistencies. This method was slow and limited. Today, CNC lathes automate this process, providing precision and speed. They can produce complex shapes with minimal human intervention.

The evolution of CNC lathes reflects a blend of innovation and advancement. In early models, the programming was basic, often relying on punch tapes. Now, sophisticated software allows for detailed designs and quick adjustments. However, even modern systems are not flawless. Errors can occur in setups or programming. This requires continuous learning and adaptation by operators. The technology is powerful, yet mastering it remains a challenge.

Recent developments focus on increasing efficiency and reducing waste. New materials and tools improve durability and accuracy. Yet, with this growth comes a need for skilled technicians. As technology advances, some operators may struggle to keep pace. Embracing change is essential but may take time. Understanding both the capabilities and limitations of CNC lathe technology is crucial for success.

Key Advantages of CNC Lathes Over Traditional Machining Methods

CNC lathes are transforming modern manufacturing. They offer precision that traditional methods often lack. With a CNC lathe, parts can be produced with minimal human intervention. This automation reduces errors and increases efficiency. Speed is another key factor. A CNC lathe can operate 24/7, driving productivity like never before.

Cost-effectiveness is noteworthy too. While the initial investment may be high, the long-term savings are significant. Lower labor costs and reduced material waste contribute to this. However, transitioning to CNC technology requires training. Operators need to adapt to new controls and software. This shift can be challenging but is integral for growth.

One must consider maintenance. CNC lathes need regular upkeep to maintain performance. Neglecting this can lead to costly downtime. Although CNC lathes excel in precision, they also present a learning curve. Understanding programming and setup takes time. These factors are crucial for maximizing the advantages of CNC technology in manufacturing.

Applications of CNC Lathes in Various Industries

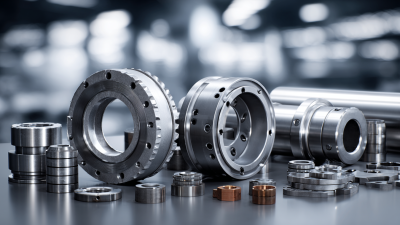

CNC lathes play a critical role in many industries today. They are used in automotive manufacturing to create precise components like gears and shafts. These machines ensure standardization and high accuracy. This leads to better performance in vehicles.

In aerospace, CNC lathes produce intricate parts for engines and wings. These parts must withstand extreme conditions, so precision is crucial. Even slight deviations can have significant consequences. The technology also extends to the medical field for creating surgical instruments. Each instrument requires specific dimensions and finishes.

Despite their importance, operators of CNC lathes face challenges. Programming errors can lead to waste and increased costs. Maintenance is another concern; poorly maintained machines can produce flawed products. Continuous training is essential to minimize mistakes. A regular review of processes can enhance efficiency and reduce issues, ensuring sustainability in modern manufacturing.

Applications of CNC Lathes in Various Industries

The Impact of CNC Lathes on Production Efficiency and Quality

CNC lathes play a pivotal role in boosting production efficiency. According to a report by the International Journal of Advanced Manufacturing Technology, companies can increase productivity by up to 30% when implementing CNC technology. This is because CNC lathes automate precision machining. They deliver consistent results, reducing the time spent on setup and operation.

Quality control is another strong point for CNC lathes. A study from the Society of Manufacturing Engineers indicates that CNC equipment reduces machining errors by over 50%. Achieving tight tolerances becomes much easier. However, reliance on CNC technology can also lead to complacency. If operators don’t actively monitor machines, unnoticed faults can affect production quality.

Moreover, integrating CNC lathes requires skilled personnel. Training staff takes time and resources. Studies show that 70% of companies face challenges in upskilling their workforce. The potential for inefficiencies exists where new users struggle to harness the machine's full capabilities. Thus, while CNC lathes significantly enhance efficiency and quality, organizations must remain vigilant in managing these changes.

Future Trends in CNC Lathe Technology and Manufacturing Integration

CNC lathe technology is rapidly evolving. As industries seek higher efficiency, integration with smart manufacturing systems becomes crucial. According to recent reports, over 70% of manufacturers are investing in CNC automation. This shift reflects a significant transformation in production methods, where precision meets speed.

Currently, CNC lathes are not just isolated machines. They are part of a larger digital ecosystem. Industry experts predict that by 2025, about 30% of all CNC machines will be linked to the Internet of Things (IoT). This connectivity allows for real-time data sharing, improving maintenance and reducing downtime. However, many manufacturers still struggle with implementation. The transition to smart manufacturing can be daunting. Not all factories are equipped for this leap.

Furthermore, training is another challenge. Skilled operators are essential for effectively utilizing advanced CNC technology. A study revealed that 40% of companies face a skill gap in their workforce. Investments in training programs are vital. Without them, the full benefits of CNC lathes remain untapped. Embracing these future trends is not just optional; it's necessary. The path forward requires a commitment to technology and workforce development.

Related Posts

-

Exploring the Future of Precision Engineering with CNC Turning Machines

-

Discover the Best Techniques for CNC Turning Parts Manufacturing Efficiency

-

Unlocking Innovation: The Vital Role of Machined Parts in Modern Manufacturing Advances

-

Maximizing Efficiency and Precision in Manufacturing with CNC Lathe Technology Insights and Trends

-

2025 Top 5 Essential Lathe Machine Parts You Need for Optimal Performance

-

Top 10 Benefits of Using Prototype Machined Parts for Your Projects