Top 10 CNC Lathe Machines for Precision Engineering in 2023

In the fast-evolving landscape of precision engineering, the importance of selecting the right CNC lathe machine cannot be overstated. As we delve into the top 10 CNC lathe machines for 2023, we recognize the critical role these machines play in achieving accuracy and efficiency in manufacturing. According to Dr. Emily Carter, a renowned expert in CNC machinery, "The right CNC lathe machine can transform not only the productivity of a shop but also the quality of the finished products." Her insight highlights the need for professionals in the industry to stay informed about the latest advancements and technologies in CNC lathes.

The selection of a CNC lathe machine directly influences operational success. These machines not only enhance the precision of component fabrication but also reduce waste and lead times, making them invaluable tools for engineers and manufacturers alike. As we explore the cutting-edge models available this year, we will consider various factors such as control systems, tooling options, and user-friendliness, ensuring that industry professionals can make informed decisions that align with their specific needs and capabilities. The landscape of CNC lathe technology is rapidly advancing, and understanding these developments is key to maintaining a competitive edge in precision engineering.

Overview of CNC Lathe Machines and Their Importance in Precision Engineering

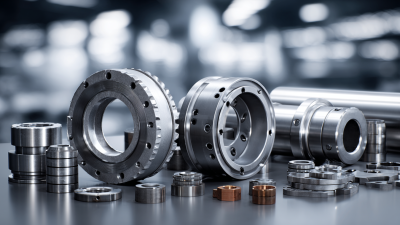

CNC lathe machines have become vital tools in precision engineering, offering unparalleled accuracy and efficiency for various manufacturing applications. These automated machines use computer numerical control technology to precisely cut, shape, and finish material, enabling engineers and manufacturers to produce intricate components with tight tolerances. The significance of CNC lathes lies not only in their ability to handle complex geometries but also in their capacity to streamline production processes, reduce waste, and enhance overall productivity.

When selecting a CNC lathe machine, it’s essential to consider the specific requirements of your projects. Factors such as the size of the workpiece, material type, and desired finish must be evaluated to ensure you choose the right machine for the job. Additionally, keeping up with software updates and maintenance schedules can significantly affect the machine's performance and longevity.

Tip: Always assess the features and capabilities of a CNC lathe in relation to your engineering needs before making a purchase. Investing time in research can yield better long-term results and save unnecessary costs.

Moreover, as industries push the envelope for more complex designs, incorporating automation and advanced programming techniques in CNC lathes can significantly enhance production capabilities. Engaging in continuous training for operators can also maximize machine usage and minimize errors during the manufacturing process.

Tip: Explore available training resources, both online and offline, to empower your team with the knowledge needed to leverage CNC technology effectively.

Key Features to Consider When Choosing a CNC Lathe Machine

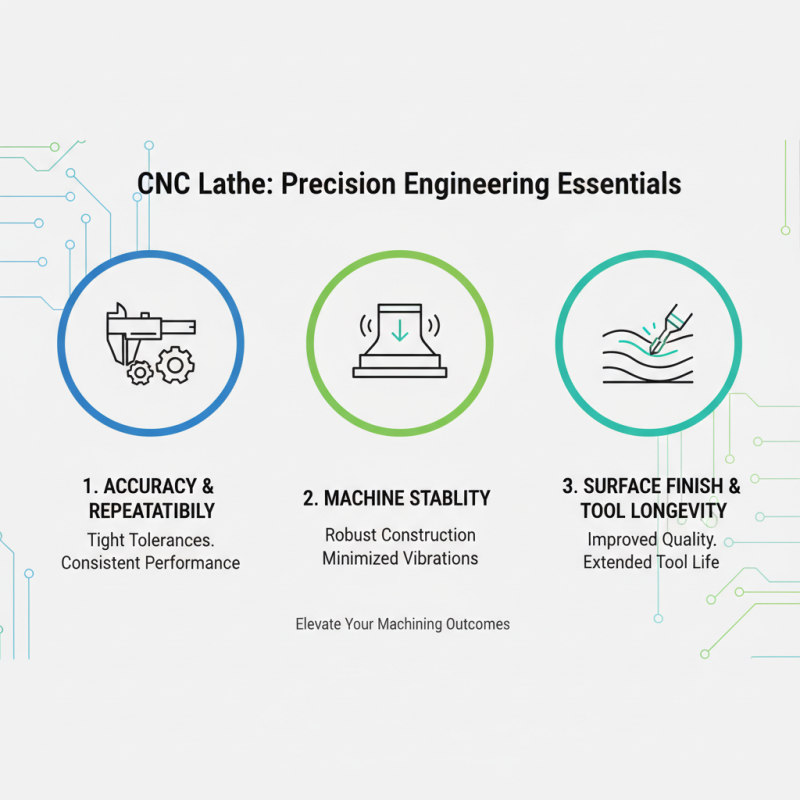

When choosing a CNC lathe machine for precision engineering, it's essential to consider several key features that can significantly influence your machining outcomes. First and foremost, accuracy and repeatability are crucial. Look for machines that offer tight tolerances and have been tested for consistent performance. The stability of the machine is also vital; a robust construction minimizes vibrations during operation, leading to improved surface finish and longevity of the tools.

Another important feature is the control system. Modern CNC lathes often come equipped with advanced control software that enhances user experience and allows for more complex operations. Consider the ease of programming, display quality, and the ability to integrate with other digital systems. Additionally, tooling options and the size of the machine’s spindle should align with your specific machining needs for optimal performance.

**Tip 1:** Before purchasing, check for compatibility with existing tools and software to avoid additional costs and learning curves.

**Tip 2:** Evaluate the level of technical support and training that comes with the machine, as this can be vital in maximizing productivity.

Taking the time to assess these features will not only help you make an informed decision but also ensure that your investment pays off in efficiency and quality output.

Top 10 CNC Lathe Machines for Precision Engineering in 2023

The landscape of precision engineering is rapidly evolving, particularly with the incorporation of advanced CNC (Computer Numerical Control) lathe machines. In 2023, these machines play a critical role in enhancing manufacturing efficiency and accuracy. According to a recent market research report by Grand View Research, the global CNC lathe market is projected to reach over $4 billion by 2025, driven by increasing demand for precision components across various industries, including aerospace, automotive, and medical.

A significant advantage of modern CNC lathe machines lies in their ability to perform complex operations with high precision. With advancements in technology, these machines now come equipped with features such as multi-axis capabilities, real-time monitoring systems, and powerful CAD/CAM integration. For instance, industry data shows that companies employing advanced CNC lathe technology report up to 20% increases in operational efficiency. The precise control over machining processes also leads to reduced waste and improved product quality, critical in sectors where tolerance levels are stringent.

Furthermore, the shift towards automation in precision engineering is more pronounced than ever. Data from the International Federation of Robotics indicates that the global installation of industrial robots, which closely complements the use of CNC machines, reached an all-time high in 2022. This trend indicates a growing reliance on automated systems to meet the rising demands for precision and production volume, ultimately positioning CNC lathe machines as vital tools for manufacturers aiming to maintain a competitive edge in 2023 and beyond.

Comparative Analysis of Performance and Price of Selected CNC Lathes

In the realm of precision engineering, selecting the right CNC lathe machine is crucial for enhancing productivity and accuracy in manufacturing processes. A comparative analysis of performance and price among various CNC lathes reveals significant variations that affect operational efficiency. Factors such as spindle speed, maximum machining diameter, and tooling configurations are pivotal in determining the performance output of these machines. Higher-end models typically offer superior capabilities, enabling faster processing times and greater precision, which can justify a higher price point for organizations committed to quality.

When evaluating CNC lathes, cost must also be weighed against the expected return on investment. While some lower-priced options may seem attractive, they often come with trade-offs in terms of build quality, durability, and technical support. Conversely, investing in a more expensive model may lead to long-term savings due to reduced maintenance costs and higher production rates. By systematically comparing these elements across a range of machines, manufacturers can make informed decisions that align with their specific engineering needs and budgetary constraints, fostering a successful integration of technology in their production lines.

Top 10 CNC Lathe Machines for Precision Engineering in 2023

| Model | Max Swing Diameter (inches) | Distance Between Centers (inches) | Spindle Speed (RPM) | Price ($) | Precision (mm) |

|---|---|---|---|---|---|

| CNC Lathe A | 12 | 30 | 3000 | 25,000 | 0.01 |

| CNC Lathe B | 14 | 36 | 2500 | 30,000 | 0.015 |

| CNC Lathe C | 10 | 24 | 3500 | 22,000 | 0.02 |

| CNC Lathe D | 16 | 40 | 2000 | 35,000 | 0.005 |

| CNC Lathe E | 18 | 50 | 1800 | 40,000 | 0.03 |

| CNC Lathe F | 20 | 60 | 1500 | 45,000 | 0.01 |

| CNC Lathe G | 22 | 70 | 1200 | 50,000 | 0.02 |

| CNC Lathe H | 24 | 80 | 1000 | 55,000 | 0.008 |

| CNC Lathe I | 26 | 90 | 800 | 60,000 | 0.005 |

| CNC Lathe J | 30 | 100 | 600 | 70,000 | 0.003 |

Future Trends in CNC Lathe Technology for Precision Engineering

As we look towards the future of CNC lathe technology, several trends are emerging that promise to enhance precision engineering significantly. One of the most notable trends is the integration of artificial intelligence and machine learning algorithms into CNC systems. These advancements enable lathes to not only execute complex machining tasks with higher accuracy but also to learn from past operations, reducing errors and optimizing workflows over time. This shift towards intelligent automation is set to redefine how precision engineering is approached, maximizing efficiency and productivity.

In addition, the rise of additive manufacturing is influencing CNC lathe technology. Manufacturers are increasingly exploring hybrid machine tools that combine additive and subtractive methods, allowing for greater flexibility and capability in creating complex geometries. This integration facilitates more innovative designs and reduces material waste, addressing the sustainability concerns of modern engineering practices.

Tips for optimizing your CNC lathe operations include regularly updating software and firmware to leverage the latest technological advancements, training operators on new features, and employing predictive maintenance strategies to minimize downtime. Investing in training programs for staff will also foster a culture of continuous improvement, ensuring that your team stays ahead in a rapidly evolving industry.

Related Posts

-

Exploring the Future of Precision Engineering with CNC Turning Machines

-

Unlocking Innovation: The Vital Role of Machined Parts in Modern Manufacturing Advances

-

Top 10 Benefits of Using Prototype Machined Parts for Your Projects

-

How to Choose the Right CNC Machine for Your Business Needs

-

Top Benefits of Using Machined Parts in Modern Manufacturing Processes

-

How to Choose the Right CNC Parts for Your Machining Projects