Understanding the Importance of CNC Lathe Parts in Precision Machining

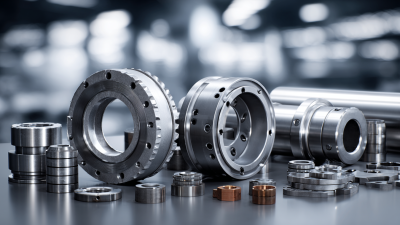

In the realm of precision machining, the significance of CNC lathe parts cannot be overstated. These components serve as the backbone of CNC lathes, facilitating the intricate processes required to produce high-quality, precise components in various industries. The role of CNC lathe parts extends beyond mere functionality; they also determine the efficiency and effectiveness of machining operations. As manufacturers strive for excellence, understanding the intricacies of these parts becomes essential for optimizing performance and achieving desired tolerances.

The precision and reliability of CNC lathe parts directly influence the accuracy of the machined products. With advancements in technology, these components have evolved to offer enhanced durability and precision, ensuring that they can withstand the demanding environments of modern manufacturing. By investing time in understanding the various types of CNC lathe parts, engineers and machinists can make informed choices about their machining processes, ultimately leading to improved productivity and reduced wastage.

As industries increasingly pivot towards automation and smart manufacturing solutions, the importance of high-quality CNC lathe parts becomes even more pronounced. These components not only contribute to the overall operational excellence but also play a crucial role in meeting the ever-growing market demands for precision-engineered products. Therefore, a comprehensive understanding of CNC lathe parts is vital for anyone involved in precision machining, ensuring that they remain competitive in an ever-evolving landscape.

The Role of CNC Lathe Parts in Precision Machining Efficiency

CNC lathe parts play a crucial role in enhancing the efficiency of precision machining, a field that increasingly relies on automation and precision to meet the demands of modern manufacturing. According to a report by the International Federation of Robotics, the global market for CNC machining is projected to grow by over 7% annually, primarily driven by advancements in automation technologies and precision engineering. CNC lathes, equipped with high-quality parts, ensure that machining operations are executed with the utmost accuracy, significantly reducing the time and costs associated with manual machining methods.

Key components of CNC lathe systems, such as spindles, tool holders, and clamping mechanisms, directly influence machining performance and output quality. High-precision parts minimize vibration and thermal deformation, which are significant factors that can compromise the accuracy of machined components. A study by the American National Standards Institute indicates that optimizing CNC lathe parts can improve operational efficiency by up to 25%, enabling manufacturers to produce parts faster while maintaining tighter tolerances.

Such enhancements not only boost productivity but also extend the lifespan of the machinery, leading to a lower total cost of ownership for manufacturers engaged in high-volume production.

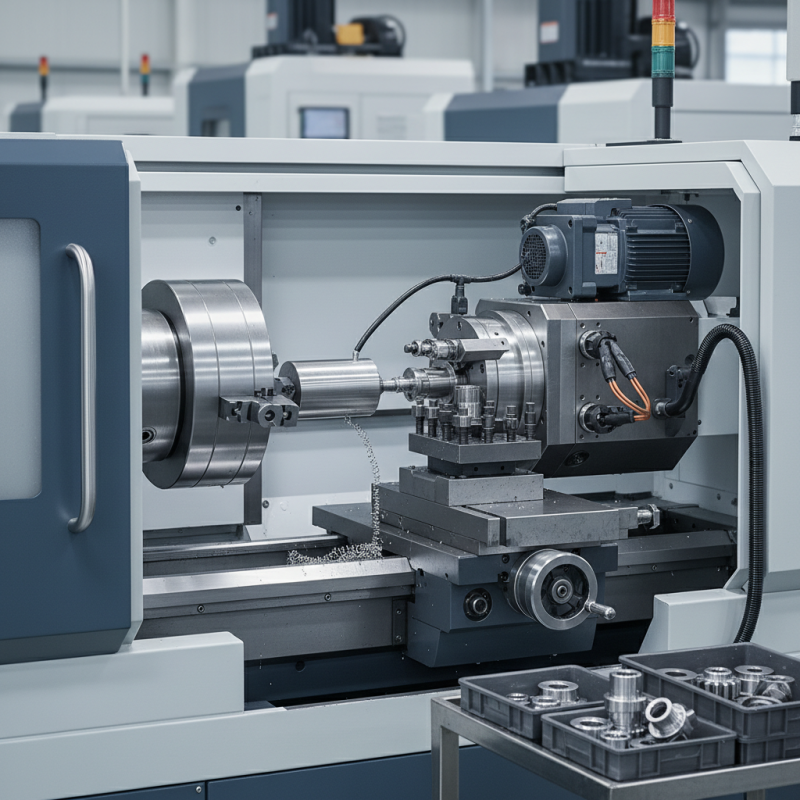

Key Components of CNC Lathe: Anatomy and Functionality Explained

CNC lathes play a crucial role in precision machining, with their key components meticulously designed to enhance efficiency and accuracy. The main parts of a CNC lathe include the spindle, turret, tailstock, and bed. The spindle is the heart of the machine, providing rotation and stability, while the turret allows for quick tool changes, which is essential for multi-step operations. The tailstock provides additional support and can hold tools for operations that require more rigidity, such as drilling or reaming. According to a report by the International Federation of Robotics, the CNC machining sector has experienced a growth rate of 8% per year, indicating the essential role of these components in boosting production capabilities.

Understanding these components' anatomy and functionality is vital for optimizing machining processes. For instance, ensuring the proper alignment of the spindle can significantly reduce wear and tear on the lathe, ultimately increasing machine life and precision. Similarly, regular inspections of the turret can lead to enhanced tool selection efficiency, resulting in higher quality outputs. A study by the Machine Tool Manufacturers' Association found that effective maintenance practices can decrease downtime by up to 25%, underscoring the importance of monitoring these key components closely.

Tips: When operating a CNC lathe, always maintain a clean work environment to prevent contamination of components, which can lead to misalignment. Additionally, regularly calibrating your tools will ensure precision and reduce inaccuracies during machining.

Understanding the Importance of CNC Lathe Parts in Precision Machining

| Component | Functionality | Material | Importance |

|---|---|---|---|

| Spindle | Holds and rotates the workpiece at high speeds. | Steel or Aluminum | Critical for precision and stability during machining. |

| Chuck | Secures the workpiece in the spindle. | Steel | Ensures workpiece alignment and stability during cutting. |

| Tool Post | Holds the cutting tool in place. | Cast Iron or Steel | Essential for precise tool positioning and adjustment. |

| Cross Slide | Allows for lateral movement of the tool. | Steel | Increases machining flexibility and precision. |

| Tailstock | Supports the end of the workpiece. | Cast Iron | Enhances support and reduces vibration during cutting. |

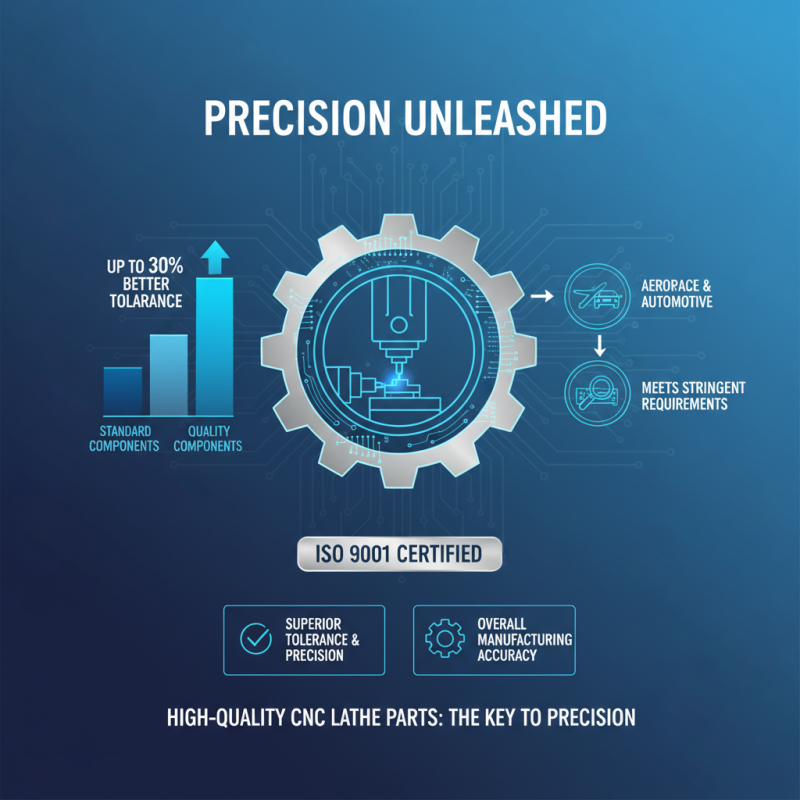

Impact of High-Quality CNC Lathe Parts on Tolerance and Precision

High-quality CNC lathe parts are integral to achieving superior tolerance and precision in precision machining. According to a recent report by the International Organization for Standardization (ISO 9001), the quality of machined components significantly influences the overall accuracy of manufacturing processes. Research indicates that using premium components can enhance tolerance levels by as much as 30%, enabling manufacturers to meet the stringent requirements of various industries, such as aerospace and automotive.

The impact of precision in machining cannot be overstated, as tight tolerances are essential for the functionality and safety of components. A study published in the Journal of Manufacturing Science and Engineering reveals that manufacturers who invest in high-quality CNC lathe parts report a 40% reduction in production errors and rework costs. This not only improves operational efficiency but also supports the long-term sustainability of production practices, as lower waste translates to reduced environmental impact. Thus, the choice of lathe parts plays a crucial role in enhancing the precision of machining operations, making it a key consideration for any manufacturer aiming for excellence in their output.

Trends in CNC Lathe Parts Manufacturing: Innovations and Technologies

The field of CNC lathe parts manufacturing is continually evolving, driven by advancements in technology and the demand for increased precision in machining processes. Innovations such as additive manufacturing and advanced materials are reshaping how CNC parts are designed and produced. For instance, integrating lightweight yet durable materials can enhance the performance of CNC lathes, allowing for faster machining speeds while maintaining accuracy. Furthermore, the use of automation and intelligent manufacturing systems enables manufacturers to optimize their production processes, reducing lead times and minimizing waste.

Tips: When selecting CNC lathe parts, consider the material compatibility to ensure longevity and performance. Additionally, staying abreast of industry trends can help you leverage new technologies in your operations, leading to more efficient machining results.

Another notable trend is the development of smart CNC machines equipped with IoT capabilities. These innovations allow for real-time monitoring and data analysis, which can facilitate predictive maintenance and enhance overall machine uptime. As manufacturers seek to improve efficiency, the implementation of such technology in CNC lathe systems will likely become more prevalent, further establishing the importance of these parts in the precision machining landscape.

Tips: To maximize the benefits of smart CNC machines, invest in training for your team to effectively use the data collected from your operations. This can lead to timely decisions and improved machining processes.

Maintenance and Care: Ensuring Longevity of CNC Lathe Parts in Production

The maintenance and care of CNC lathe parts is crucial for ensuring the longevity and optimal performance of precision machining operations. These components are subjected to considerable stress and wear during the machining process, which can lead to diminished accuracy and potential downtime if not properly maintained. Regular inspection and cleaning of these parts are essential practices that help identify wear and tear at early stages, allowing for timely repairs or replacements. Implementing a routine maintenance schedule can significantly reduce the risk of unexpected equipment failures and improve overall productivity.

In addition to regular inspections, proper lubrication is key to extending the life of CNC lathe parts. Lubricants reduce friction between moving parts, helping to prevent overheating and excessive wear. Selecting the appropriate type of lubricant for specific applications and ensuring it is applied in the right amounts can greatly enhance the efficiency and lifespan of the machine. Furthermore, operators should be educated about the importance of maintaining cleanliness around the machine, as debris and contaminants can compromise the integrity of precision components. By prioritizing maintenance and care, manufacturers can keep their CNC lathes operating smoothly, ensuring high-quality production outputs.

Importance of CNC Lathe Parts in Precision Machining

Related Posts

-

Discover the Best Techniques for CNC Turning Parts Manufacturing Efficiency

-

Top 10 CNC Turning Parts Manufacturers for Precision Engineering Solutions

-

Unlocking Innovation: The Vital Role of Machined Parts in Modern Manufacturing Advances

-

Top 10 CNC Milling Machines for Precision Machining in 2023

-

Understanding the Benefits of Large Part CNC Machining for Precision Manufacturing

-

How to Choose the Right CNC Machine for Your Business Needs