Unlocking Precision: How CNC Machining Parts are Revolutionizing Modern Manufacturing

In today's rapidly evolving manufacturing landscape, the integration of advanced technologies has become essential for maintaining competitiveness and efficiency. One such innovation is the adoption of CNC machining parts, which are transforming production processes across various industries. According to a report by Markets and Markets, the global CNC machine market is expected to reach $100 billion by 2025, highlighting a significant shift towards automated manufacturing solutions.

CNC machining parts not only enhance precision and reduce human error but also enable the production of complex geometries that were previously impractical. Furthermore, a study from Technavio projected that the increasing demand for customization in manufacturing will drive the growth of CNC technology, positioning it as a cornerstone of modern production strategies.

As businesses strive to optimize their operations, the role of CNC machining parts in revolutionizing processes and improving scalability cannot be overstated.

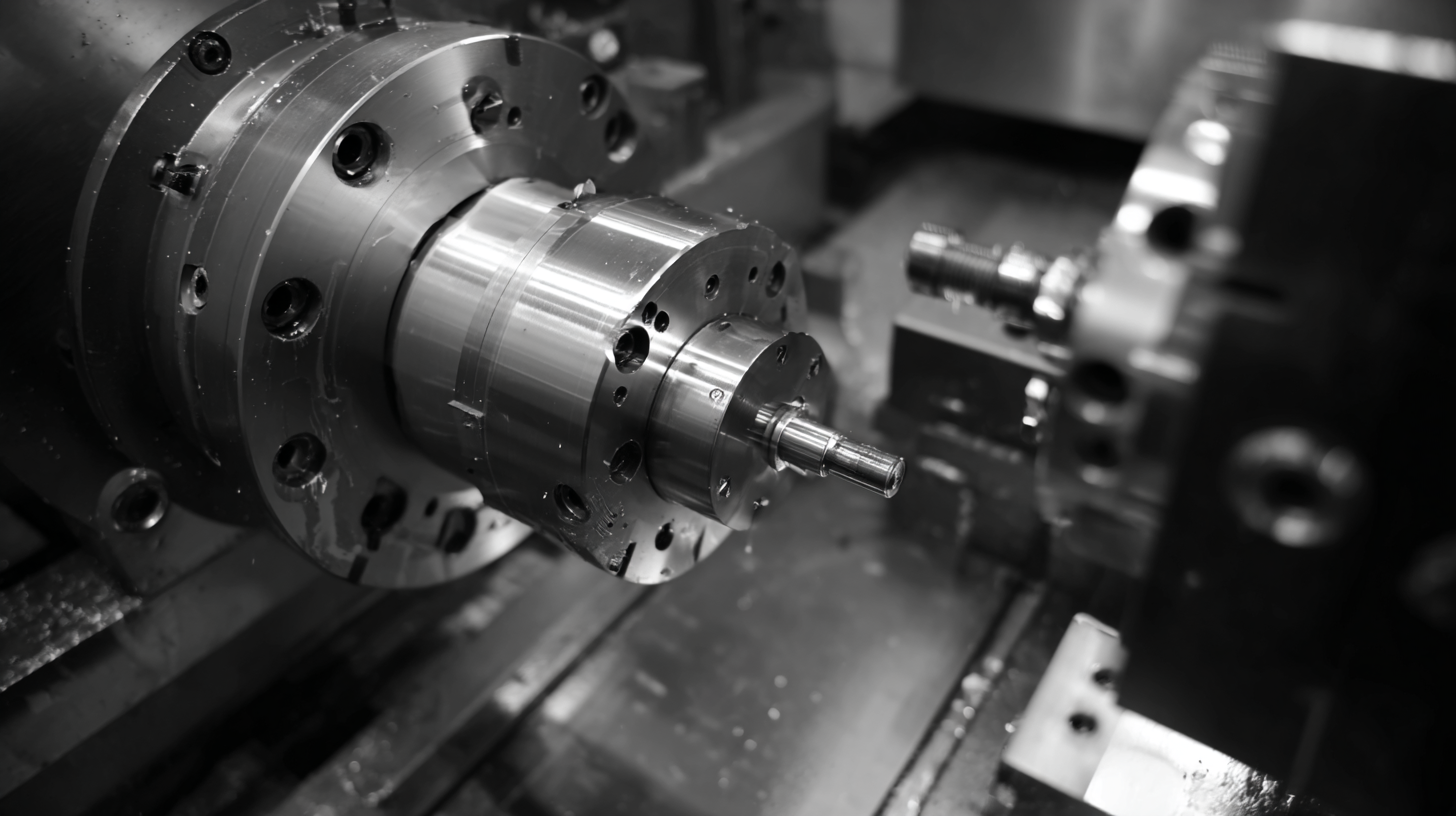

Emergence of CNC Machining: A Game Changer in Manufacturing Precision

CNC machining has emerged as a transformative force in modern manufacturing, redefining the standards of precision and efficiency. With the global CNC machining market projected to reach USD 100 billion by 2025, according to a report by MarketsandMarkets, industries are increasingly adopting this technology to meet the growing demands for accuracy and productivity. CNC (Computer Numerical Control) machines operate through computer programming, allowing manufacturers to create complex components with remarkable consistency and reduced human error. This level of precision is vital in sectors such as aerospace, automotive, and healthcare, where even the slightest deviation can lead to significant repercussions.

Tips: To ensure optimal performance with CNC machining, manufacturers should invest in regular maintenance and calibration of their machines. This not only prolongs the lifespan of the equipment but also enhances production quality. Additionally, integrating advanced software solutions can streamline the design and simulation processes, allowing for quicker adjustments and modifications.

Moreover, the ability to produce custom parts at scale is what truly sets CNC machining apart. As businesses strive for differentiation in their products, CNC technology enables them to innovate without the limitations of traditional manufacturing processes. Estimates show that CNC machining can reduce lead times by up to 75%, providing companies with a critical edge in highly competitive markets. By embracing these advancements, manufacturers can unlock new potentials and drive growth in their operations.

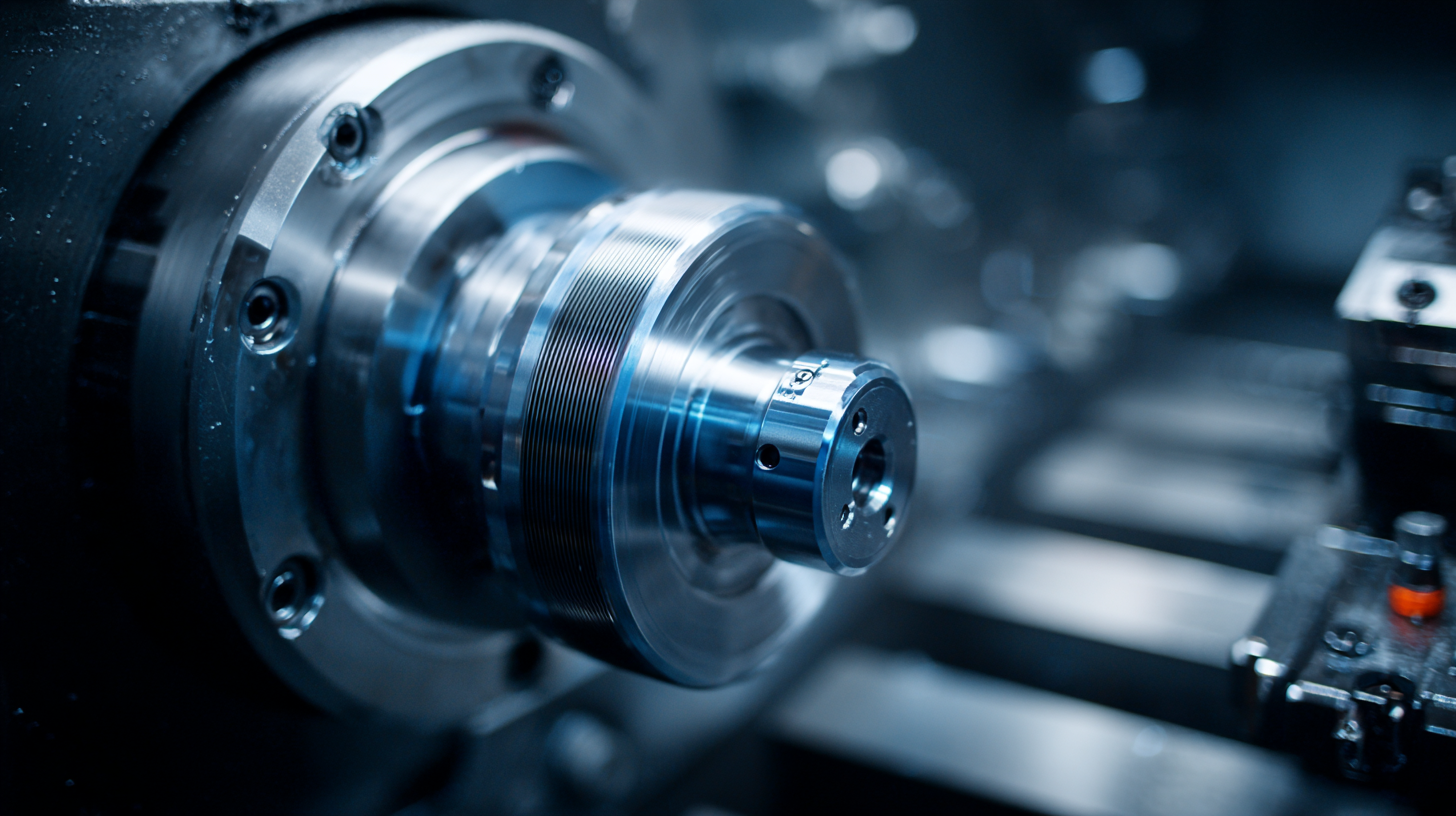

The Impact of CNC Machining on Production Efficiency and Cost Reduction

The impact of CNC machining on production efficiency and cost reduction cannot be overstated. With its ability to produce complex parts with high precision at scale, CNC machining has transformed traditional manufacturing processes. This technology minimizes human error and significantly reduces material waste, ensuring that manufacturers can deliver products faster and cheaper. By streamlining workflows and optimizing machining processes, companies can increase their output while maintaining quality.

Tips for integrating CNC machining into your production line include starting with a clear understanding of your manufacturing goals. Evaluate the parts you produce to identify which can benefit most from CNC technology. Additionally, invest in training for your staff to ensure they are well-equipped to handle the advanced machinery. Emphasizing collaboration between design and manufacturing teams can also lead to more efficient processes, as it allows for quick adjustments and innovations.

Another crucial tip is to maintain your CNC machines regularly. A well-maintained machine not only operates more efficiently but also has a longer lifespan, which further contributes to cost savings. Ensure that you establish a routine maintenance schedule to avoid unexpected downtime that can disrupt production and incur additional costs. Implementing these strategies can help you fully leverage the advantages of CNC machining in achieving operational efficiency.

Unlocking Precision: The Impact of CNC Machining on Production Efficiency and Cost Reduction

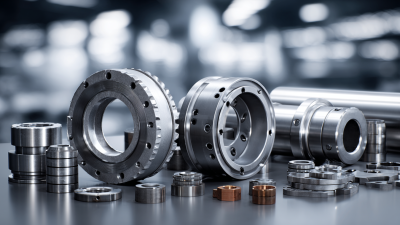

Key Industries Benefiting from CNC Machining Innovations

CNC machining has emerged as a pivotal technology in various key industries, transforming manufacturing processes with unparalleled efficiency and precision. The aerospace industry, for instance, benefits immensely from CNC machining's ability to produce complex components with strict tolerances. These components, such as turbine blades and structural frames, require a level of accuracy that traditional manufacturing methods often struggle to achieve. The reduction in human error and increased repeatability not only enhances safety but also optimizes performance in high-stakes applications.

Another sector reaping the rewards of CNC machining innovations is the medical industry. Custom implants and surgical instruments must meet exact specifications to ensure patient safety and successful outcomes. CNC machines allow for rapid prototyping and production of these critical devices, enabling manufacturers to respond swiftly to evolving needs and design improvements. As technology advances, the integration of materials like titanium and advanced polymers in CNC machining continues to push the boundaries, allowing for lighter, stronger, and biocompatible products. This responsiveness to industry demands and design complexities exemplifies how CNC machining is revolutionizing modern manufacturing across various fields.

Understanding the Role of CNC Machining in Industry 4.0 Transformation

CNC machining plays a pivotal role in the transformation of manufacturing within the framework of Industry 4.0. By integrating advanced digital manufacturing technologies, CNC machining enhances productivity across a multitude of sectors. This evolution is characterized by the seamless adoption of automation, IoT, and AI, which collectively streamline operations and produce high-quality outputs with unprecedented precision. The rise of smart manufacturing software further accelerates factory processes, making it easier for manufacturers to adapt to changing demands and optimize their workflows.

As industries increasingly shift towards digital solutions, the CNC slitting lathes and milling machine markets are set to experience significant growth. Projected to reach USD 2.8 billion and USD 116,722.7 million respectively by the mid-2030s, these markets highlight the demand for advanced machining tools that facilitate efficient production. The convergence of CNC technology with smart automation not only drives economic growth but also lays the foundation for sustainable manufacturing practices that meet the evolving challenges of today's industrial landscape.

Future Trends in CNC Machining Technology: Data-Driven Insights and Projections

As CNC machining technology continues to evolve, the integration of data-driven insights is becoming increasingly pivotal. One of the most promising future trends is the implementation of artificial intelligence and machine learning algorithms that can predict equipment failures before they occur. By analyzing historical and real-time data, manufacturers can optimize maintenance schedules, reduce downtime, and enhance the overall efficiency of the production process. This proactive approach not only saves costs but also improves the quality of machined parts, ensuring they meet stringent specifications consistently.

Another significant trend is the rise of additive manufacturing techniques alongside traditional CNC processes. This hybrid approach allows for greater design freedom and material efficiency, which is particularly beneficial in industries like aerospace and medical devices where precision and weight are critical. Moreover, advancements in IoT (Internet of Things) technologies are facilitating better connectivity between machines, leading to smarter factories. This interconnectedness allows for real-time monitoring and adjustments in the machining process, further pushing the boundaries of precision and customization in modern manufacturing.

Unlocking Precision: How CNC Machining Parts are Revolutionizing Modern Manufacturing

| Dimension | Metric (mm) | Futuristic Trends |

|---|---|---|

| Speed of Machining | 1000 - 10000 RPM | Increased automation and AI integration |

| Material Variety | Aluminium, Steel, Plastic | Emerging materials like composites and titanium alloys |

| Accuracy | ±0.01 mm | Advancements in sensor technology for real-time monitoring |

| Cost Efficiency | $$ per part | Adoption of cloud computing to reduce operational costs |

| Production Volume | 100 - 10000 units | Shift towards small-batch production to cater to customization |

Related Posts

-

Discover the Best Techniques for CNC Turning Parts Manufacturing Efficiency

-

Exploring the Future of Manufacturing: How CNC Machine Tools Revolutionize Precision Engineering

-

Exploring the Future of Precision Engineering with CNC Turning Machines

-

Unlocking Innovation: The Vital Role of Machined Parts in Modern Manufacturing Advances

-

Understanding the Benefits of Large Part CNC Machining for Precision Manufacturing