Top 10 CNC Turning Center Benefits Your Business Should Know?

In today's competitive landscape, businesses must leverage advanced manufacturing technologies. A CNC turning center stands out among these innovations. It enhances precision, speed, and efficiency, driving profitability. According to a report by the International Federation of Robotics, CNC machine tools are projected to grow significantly, reflecting their importance in the industry.

Experts emphasize the value of CNC turning centers. "These machines enable companies to streamline operations and maintain quality," says Dr. Jane Smith, a leading expert in CNC technology. This statement highlights a critical point: while businesses recognize the benefits, many still overlook potential pitfalls. Companies may struggle with initial costs or the learning curve. This is not uncommon in an evolving market.

The reality is that adopting a CNC turning center requires careful consideration. It's essential to evaluate your production needs and workforce readiness. Despite the challenges, the long-term advantages are compelling. Embracing this technology can redefine a business's operational capabilities. Understanding these aspects is crucial for making informed decisions.

Benefits of Enhanced Precision in CNC Turning Centers

CNC turning centers are transforming manufacturing with enhanced precision. This technology allows for tight tolerances, ensuring parts fit perfectly. For industries like aerospace and automotive, this precision is crucial. A small error can lead to significant failures.

Tip: Regular training for operators can improve the quality of output. Well-trained staff understand how to set up the machines correctly. They can troubleshoot unexpected issues effectively. Enhanced skills lead to better accuracy and fewer errors.

Investing in CNC turning centers can save costs in the long run. Reduced material waste is a significant advantage. However, not all shops may see immediate results. It takes time to adapt and refine processes. Continuous improvement should be a key focus for businesses.

Tip: Review production data regularly. Analyze areas that need improvement. Identify trends that could point to precision issues. Engaging operators in these reviews can bring fresh perspectives. Collaboration often sparks innovative solutions.

Top 10 CNC Turning Center Benefits Your Business Should Know

| Benefit | Description | Impact on Business |

|---|---|---|

| Enhanced Precision | CNC turning centers provide high accuracy in creating complex parts. | Reduces waste and rework costs. |

| Increased Efficiency | Automated processes minimize handling time. | Higher production rates improve ROI. |

| Cost-Effectiveness | Reduction in labor costs due to automation. | Lowered overall production expenses. |

| Flexibility in Design | Allows for rapid changes in design with ease. | Enables quick adaptation to market demands. |

| Improved Safety | Automating dangerous or repetitive tasks enhances worker safety. | Lowers risk of workplace accidents. |

| Reduced Lead Times | Faster production cycles lead to quicker delivery. | Improves customer satisfaction and retention. |

| Increased Scalability | Easily scale up production to meet demand. | Supports business growth effectively. |

| Enhanced Product Quality | Consistent production quality results from precise machining. | Builds brand reliability and trust. |

| Data Collection | Integration with software for tracking production metrics. | Facilitates informed decision-making. |

| Sustainability | Optimized processes lead to less scrap and energy consumption. | Supports eco-friendly business practices. |

Increased Efficiency and Production Speed with CNC Turning Centers

CNC turning centers greatly enhance efficiency in manufacturing processes. These machines can precisely shape materials into complex designs. Set up times are often reduced significantly. This allows for quicker transitions between different production runs. As a result, businesses can respond quickly to market demands.

Moreover, CNC turning centers boost production speed. High-speed operations mean that more parts are produced in less time. However, the learning curve for operating these machines can be steep. Operators must have a solid understanding of programming. Otherwise, errors can lead to wasted materials and time. Training is essential to mitigate these risks.

Increased production capabilities can also have some drawbacks. Relying solely on automation may limit creativity in design processes. Human intuition can provide unique insights that machines might miss. So, while CNC turning centers offer significant benefits, it’s important to balance their use with human oversight. Finding the right mix can lead to the best outcomes for any manufacturing business.

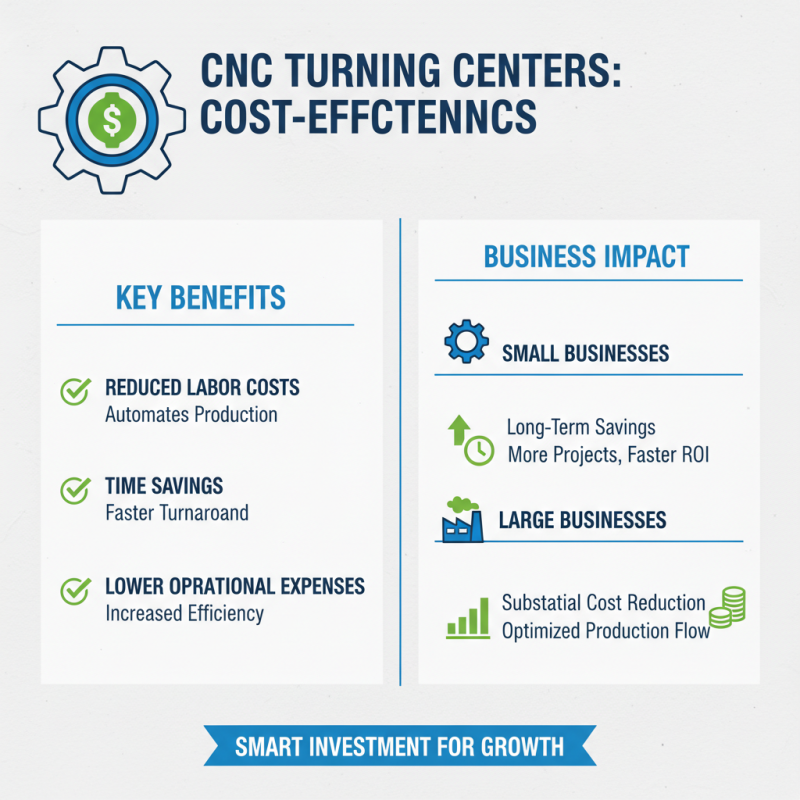

Cost-Effectiveness of CNC Turning for Small and Large Businesses

CNC turning centers provide significant cost-effectiveness for both small and large businesses. These machines reduce labor costs by automating production processes. This efficiency saves time, which translates to lower operational expenses. For small enterprises, the initial investment may seem daunting, but the long-term savings can be substantial. Many small shops report faster turnaround times, allowing them to take on more projects.

Large businesses also see benefits. High-volume production demands precision and consistency, which CNC turning centers deliver. They minimize material waste, further enhancing cost-efficiency. However, not every business may need such advanced machinery. Some may find it hard to justify the cost. It’s crucial to assess whether the production scale justifies the investment.

Over-reliance on automation can lead to issues. Skills may become outdated, as employees might not engage with manual processes. Businesses should evaluate their workforce's adaptability. Balancing automation with traditional methods could lead to a more robust operation. Think carefully about how your business can harness the power of CNC turning while maintaining a versatile skill set among staff.

Versatility of CNC Turning Centers in Different Industries

CNC turning centers are transforming industries. Their versatility is unmatched. In the automotive sector, they produce precise components. From shafts to gears, accuracy is critical. CNC machines can adapt quickly to different designs. This leads to faster production times.

In aerospace, precision is life or death. CNC turning centers create complex parts like turbine housings. Their flexibility allows for different materials. This includes aluminum and titanium. However, the skill gap remains a concern. Not all operators can maximize this technology's potential.

Medical manufacturing benefits as well. Custom implants require exact specifications. CNC turning achieves this with ease. The customization options are vast, catering to specific patient needs. Still, quality control must be a continuous focus. Mistakes can lead to dire consequences. Companies must invest in training and testing processes.

Streamlined Workflow and Reduced Labor Costs with Automation

Automation in CNC turning centers significantly streamlines workflows and reduces labor costs. Reports indicate that implementing automation can enhance productivity by up to 30%. This improvement is crucial for businesses seeking competitive advantages. Automated systems operate with minimal downtime, allowing for continuous production.

Labor costs account for a significant percentage of manufacturing overhead. By adopting CNC turning centers, companies can reduce their reliance on manual labor. A study found that automation can decrease employee workload by 50% in specific tasks. This shift often leads to employees focusing on more strategic roles, rather than repetitive tasks. However, some companies hesitate to embrace this change fully, possibly due to the initial investment required.

Moreover, while automated systems improve efficiency, they may also introduce complexities. Some operators might struggle with programming and maintenance. The learning curve can lead to temporary disruptions during transition periods. Companies must be prepared to invest in training programs to overcome these challenges. Proper support and training can help mitigate these potential drawbacks, ensuring that operations run smoothly in the long term.

Top 10 Benefits of CNC Turning Centers

Related Posts

-

Top 10 CNC Turning Parts Manufacturers for Precision Engineering Solutions

-

Exploring the Future of Manufacturing: How CNC Machine Tools Revolutionize Precision Engineering

-

Top Benefits of Fast CNC Machining for Your Manufacturing Needs

-

Why Choose a CNC Machine for Your Manufacturing Needs?

-

Why Choosing the Right CNC Parts is Essential for Your Machinery Performance

-

Top 2025 CNC Mill Models: What to Consider for Precision Machining