Ultimate Guide to CNC Turning Machine Benefits and Applications for Beginners

In the ever-evolving landscape of manufacturing, the CNC turning machine stands out as a pivotal technology that significantly enhances productivity and precision. Renowned industry expert John Smith, who has over two decades of experience in the field, emphasizes the importance of this machinery, stating, "The CNC turning machine isn’t just a tool; it’s the backbone of modern manufacturing processes." This guide aims to illuminate the myriad benefits and versatile applications of CNC turning machines for beginners, providing essential insights into why they are indispensable in various industries.

CNC turning machines offer remarkable efficiency, enabling manufacturers to produce complex parts with high accuracy and minimal waste. As they rapidly become the preferred choice for precision machining, understanding their functionalities and advantages is crucial for newcomers entering the field. From automotive components to intricate medical devices, the applications of CNC turning technology are vast and varied, making it a critical area of knowledge for those aspiring to thrive in today’s manufacturing world.

As we delve deeper into this ultimate guide, we will explore both the technological benefits and practical applications of CNC turning machines. By doing so, we aim to equip beginners with the foundational knowledge necessary to harness this powerful technology effectively.

Understanding CNC Turning Machines: Key Features and Functions

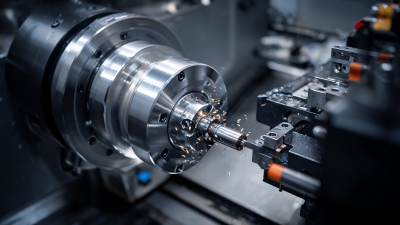

CNC turning machines play a crucial role in modern manufacturing, offering precision and efficiency that traditional machining methods cannot match. At the heart of these machines is the ability to rotate the workpiece against a stationary cutting tool. This unique feature allows for the creation of complex cylindrical shapes, making CNC turning ideal for producing parts like shafts, bushings, and fittings. The computer-numerical control (CNC) aspect automates these processes, enabling high repeatability and minimizing human error, which is essential for industries requiring stringent tolerances.

Key features of CNC turning machines include their advanced programming capabilities, which allow manufacturers to create intricate designs with ease. Operators can input specifications directly into the machine, and the CNC system adjusts the movements accordingly, thus improving productivity. Moreover, many CNC turning machines are equipped with multi-axis capabilities, enabling the machining of more complex geometries in a single setup. This reduces the need for multiple machines or setups and streamlines the manufacturing process, ultimately saving time and resources. With their numerous functions and adaptability, CNC turning machines are an invaluable asset for any manufacturing operation looking to enhance its capabilities and output quality.

Benefits of CNC Turning Machines in Modern Manufacturing Industries

CNC turning machines have become a cornerstone of modern manufacturing industries, offering numerous advantages that enhance production efficiency and accuracy. One of the primary benefits of these machines is their ability to produce complex geometries with high precision. This capability is vital in industries such as aerospace and automotive, where even the slightest deviation can result in significant performance issues. Additionally, CNC turning machines can operate continuously with minimal human intervention, reducing labor costs and increasing productivity.

Tips for beginners looking to implement CNC turning machines include investing in quality training for operators to fully leverage the technology’s capabilities. Proper programming and tool selection are crucial to achieving the desired outcomes while minimizing material wastage. Understanding the components and features of CNC turning machines can also empower manufacturers to make informed decisions about their production processes.

Furthermore, the versatility of CNC turning machines makes them suitable for a variety of applications, from prototyping to high-volume production runs. They are capable of working with diverse materials, such as metals, plastics, and composites, making them essential tools across multiple sectors. By embracing CNC turning technology, manufacturers can not only increase their competitiveness but also innovate and adapt to the ever-evolving market demands.

Exploring the Applications of CNC Turning: From Aerospace to Medical

CNC turning machines have revolutionized various industries due to their precision and efficiency. One of the most notable applications is in the aerospace sector, where components require exact specifications to meet stringent safety and performance standards. According to a report from the Aerospace Industries Association, advanced CNC machining techniques have increased the production speed by up to 30%, allowing manufacturers to keep pace with rising demand while maintaining high safety regulations. The intricate nature of aerospace parts, including turbine blades and structural components, benefits immensely from the capability of CNC turning to produce complex geometries with tight tolerances.

In the medical field, CNC turning machines contribute significantly to the production of surgical instruments and implants. A study published in the Journal of Biomedical Engineering highlights that the precision of CNC turning reduces the risk of post-operative complications, as medical devices must not only fit perfectly but also perform reliably under stress. The report indicates that the use of CNC technology in medical manufacturing has grown by 15% annually, driven by increasing advancements in personalized medicine and the rising need for custom implants. The ability of CNC turning machines to consistently deliver high-quality parts means they are an essential tool in enhancing patient outcomes and advancing medical technology.

Applications of CNC Turning Machines Across Various Industries

Comparative Analysis: CNC Turning vs. Traditional Machining Techniques

CNC turning and traditional machining techniques serve essential roles in the manufacturing industry, yet they differ significantly in efficiency, precision, and versatility. According to a report by the International Federation of Robotics, CNC machines can enhance production rates by up to 30% compared to manual machining methods. This is primarily due to the automation and computer control in CNC turning, which allows for consistent quality and reduced human error. Traditional machining, while effective for certain applications, often relies heavily on operator skills and can lead to variability in machined parts.

When considering the materials utilized, CNC turning is adept at handling various materials ranging from metals to plastics, enabling manufacturers to expand their capabilities. A study by the American Society of Mechanical Engineers highlights that CNC turning can achieve tolerances as tight as ±0.001 inches, a feat challenging for traditional techniques, which may not offer the same precision. This allows CNC turning to accommodate a wider range of complex geometries and intricate designs, giving it a distinct advantage in competitive manufacturing landscapes.

Tips: For beginners opting for CNC turning, it's crucial to invest time in understanding the programming languages used, as this knowledge underpins the operation efficiency of the machines. Additionally, familiarity with 3D CAD modeling tools can significantly streamline the transition from design to machining. Lastly, always prioritize regular maintenance schedules for your CNC machines to ensure long-term operational reliability and safety.

Industry Statistics: Impact of CNC Technology on Production Efficiency

CNC technology has significantly transformed the manufacturing sector, improving production efficiency across various industries. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach USD 100.96 billion by 2026, with a compound annual growth rate (CAGR) of 6.5% from 2021 to 2026. This growth is largely driven by the increasing demand for automation and precision in manufacturing processes. CNC turning machines, in particular, enhance production efficiency by automating repetitive tasks, reducing human error, and ensuring consistent quality in parts manufacturing.

In addition to efficiency, CNC technology positively impacts production timelines. A study by Deloitte indicates that manufacturers utilizing CNC systems can achieve production rates that exceed traditional machining methods by up to 50%. This improvement allows businesses to meet tight deadlines and respond swiftly to market demands while maintaining high levels of precision. Furthermore, integrating CNC technology results in lower material wastage, as machines can perform more intricate tasks with a higher degree of accuracy, which aligns with sustainability goals within the industry. These statistics underscore the profound influence of CNC turning machines on modern manufacturing practices, particularly for those looking to enhance operational capabilities and reduce costs.

Related Posts

-

Top Benefits of Fast CNC Machining for Your Manufacturing Needs

-

Discover the Best Techniques for CNC Turning Parts Manufacturing Efficiency

-

Exploring the Future of Precision Engineering with CNC Turning Machines

-

2025 Top 10 CNC Machines: Unveiling the Future of Precision Engineering and Automation

-

2025 How to Choose the Best CNC Turning Center for Your Manufacturing Needs

-

2025 How to Choose the Best CNC Turning Center for Your Machining Needs