Top 10 Essential CNC Lathe Parts You Need for Optimal Machining Performance

In the world of manufacturing, the efficiency and precision of machining processes heavily rely on the quality and functionality of CNC lathe parts. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach $100 billion by 2025, indicating a robust demand for high-quality machining tools and components. As CNC technology continues to evolve, the specific parts utilized in CNC lathes play a crucial role in enhancing productivity, accuracy, and overall performance in machining applications.

Proper selection and maintenance of CNC lathe parts not only extend the lifespan of the equipment but also significantly contribute to the reduction of production costs. A study published in the Journal of Manufacturing Processes highlights that optimized CNC systems can improve manufacturing efficiency by up to 30%. Therefore, understanding the essential components that comprise an effective CNC lathe—such as spindles, tool holders, and drive motors—becomes invaluable for operators aiming to achieve operational excellence in their machining endeavors.

This article will explore the top 10 essential CNC lathe parts you need for optimal machining performance, providing insight into their functions and the impact they have on productivity. By focusing on the fundamental components that drive CNC lathe operations, manufacturers can make informed decisions to enhance their machining capabilities and remain competitive in an ever-evolving market.

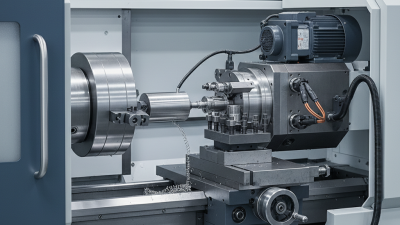

Key Components of CNC Lathes for Enhanced Machining Efficiency

CNC lathes are pivotal in achieving high precision and efficiency in machining processes. Among the essential components that contribute to enhanced machining performance are the spindle, tool turret, and tailstock. The spindle provides the rotational motion necessary for the workpiece, ensuring stability and speed, which are crucial for intricate machining tasks. A well-designed spindle minimizes vibrations, allowing for smoother operations and superior surface finishes.

The tool turret is another key component that significantly enhances productivity. With the ability to hold multiple tools and rapidly switch between them, the turret reduces downtime associated with tool changes. This capability not only streamlines the machining process but also allows for more complex part geometries to be produced in a single setup. Additionally, the tailstock plays a vital role in supporting long workpieces during machining, enabling better accuracy and reducing the risk of deformation.

Together, these components, along with others such as the CNC controller and bed, create a synergistic system that maximizes machining efficiency. By selecting high-quality parts and maintaining them, operators can ensure optimal performance from their CNC lathes, leading to improved output and reduced production costs.

Top 10 Essential CNC Lathe Parts for Optimal Machining Performance

Understanding the Role of the Spindle in CNC Lathe Operations

The spindle is a crucial component in CNC lathe operations, serving as the primary interface between the machine and the workpiece. It is responsible for rotating the workpiece at precise speeds, enabling clean and accurate cuts. The spindle's speed and torque can significantly affect the machining performance, influencing the quality of the finished product. An optimal spindle setup ensures that your lathe can handle different materials and cutting techniques, allowing for versatility in production processes.

Tips: Regular maintenance of the spindle is essential to enhance its performance and longevity. Ensure proper lubrication to minimize friction and wear. Inspect the spindle bearings periodically for any signs of damage or irregular noise, which could indicate potential issues that might affect machining accuracy.

Moreover, considering the correct spindle speed for the material being machined is pivotal. Each material has specific cutting speeds that optimize efficiency and prevent overheating or tool wear. Adjusting the spindle speed according to the type of operation, whether drilling, turning, or facing, will lead to better surface finishes and longer tool life. By paying attention to these key aspects, you can maximize the benefits your CNC lathe provides.

Importance of Tool Holders in CNC Machining Performance

In the realm of CNC machining, tool holders play a crucial role in ensuring optimal performance. They serve as the interface between the cutting tools and the machine itself, providing stability and precision during operations. A well-designed tool holder can significantly reduce vibration, enhance cutting efficiency, and improve the overall accuracy of the machining process. By maintaining the correct alignment and rigidity, tool holders enable consistent results, which are vital for meeting quality standards in production.

When choosing tool holders, consider the type of operations you frequently perform. For example, collet chucks are excellent for providing a firm grip on tools, while quick-change systems can boost productivity by allowing rapid tool swaps. It’s essential to regularly inspect and maintain your tool holders to prevent wear and ensure they remain in optimal condition. Keeping them clean and well-lubricated can enhance their longevity and performance.

Tips: Always match the tool holder with the specific type of cutting tool to maximize efficiency. Additionally, using the correct torque specifications when securing tools in place can prevent slippage and ensure safety during machining. Finally, invest in high-quality materials for tool holders to withstand the rigorous demands of CNC machining processes.

The Functionality of the Chuck and Its Impact on Workpieces

The chuck is a vital component of any CNC lathe, serving as the mechanism that holds and secures workpieces during the machining process. Its design and functionality directly influence the precision and quality of the final product. A well-functioning chuck ensures that the workpiece remains stable, minimizing vibrations and allowing for more accurate cuts. This stability is crucial, as even minor movements can lead to dimensional inaccuracies, compromising the integrity of the finished part.

Different types of chucks, such as three-jaw and four-jaw designs, offer varying levels of gripping force and versatility. The choice of chuck will depend on the shape and size of the workpiece being machined. A three-jaw chuck, for example, is ideal for symmetrical components, quickly providing a firm grip. In contrast, a four-jaw chuck allows for more flexibility in securing irregularly shaped workpieces, enabling precise adjustments for centering. Ultimately, the impact of the chuck on machining performance cannot be overstated, as it plays a crucial role in achieving the desired tolerances and surface finishes critical in various manufacturing applications.

Top 10 Essential CNC Lathe Parts You Need for Optimal Machining Performance

| Part Name | Functionality | Impact on Workpieces | Material | Maintenance Tips |

|---|---|---|---|---|

| Chuck | Holds the workpiece securely | Directly affects precision and stability | Steel or Aluminum | Regular cleaning and lubrication |

| Tailstock | Provides support and alignment | Enhances accuracy and reduces deflection | Cast Iron | Check for wear regularly |

| Tool Post | Holds and positions cutting tools | Affects cutting tool stability | High Carbon Steel | Lubricate to prevent rust |

| Spindle | Houses the rotating mechanism | Influences rotational accuracy | Steel | Ensure proper bearing lubrication |

| Bed | Provides stability and strength | Directly affects overall machine rigidity | Casting Iron | Keep clean to avoid rust |

| Slideways | Guides the movement of the carriage | Affects precision of cutting motions | Cast Iron | Regular lubrication to prevent wear |

| Carriage | Moves tools and supports them | Impacts tool path and accuracy | Steel | Maintain adjustable components |

| Lead Screw | Drives the carriage linearly | Affects linear positioning accuracy | Acme Threaded Steel | Keep free of debris and lubricate |

| Power Switch | Controls machine power | Essential for safe operation | Plastic Composite | Test functionality regularly |

| Coolant System | Keeps tools and workpieces cool | Reduces thermal distortion | Metal & Plastic | Check fluid levels and cleanliness |

Maintaining Precision with CNC Lathe Guides and Ways

When it comes to CNC lathe machining, the precision of the guides and ways plays a crucial role in achieving optimal performance. These components support the movement of the tooling and workpiece, directly influencing the accuracy of the cuts and the overall quality of the finished product.

The guides, designed to maintain a consistent path for the cutting tools, must be robust and precisely manufactured to reduce any potential for movement or vibration. A well-maintained guide system ensures that even the most intricate designs can be replicated with minimal deviation, making precision a hallmark of successful machining.

Moreover, the ways of the CNC lathe are equally significant in maintaining overall machine performance. These linear surfaces allow for the smooth sliding of components, significantly affecting machine efficiency and lifespan.

Regular inspection and maintenance of the ways can prevent wear and tear, which would otherwise lead to increased friction and reduced accuracy over time. Implementing proper lubrication, adjusting alignment, and cleaning the ways are essential practices for keeping the machining process running at its peak. By paying close attention to these vital elements, machinists can ensure that their CNC lathes deliver high-quality results consistently, minimizing downtime and maximizing productivity.

Related Posts

-

Understanding the Importance of CNC Lathe Parts in Precision Machining

-

Top 5 Advantages of Using Prototype Machined Parts for Efficient Production

-

2025 How to Choose the Best CNC Turning Center for Your Machining Needs

-

Exploring the Future of Manufacturing: How CNC Machine Tools Revolutionize Precision Engineering

-

Exploring the Future of Precision Engineering with CNC Turning Machines

-

Top 10 CNC Milling Machines for Precision Machining in 2023