Top Lathe Machine Parts Essential Components for Precision Engineering?

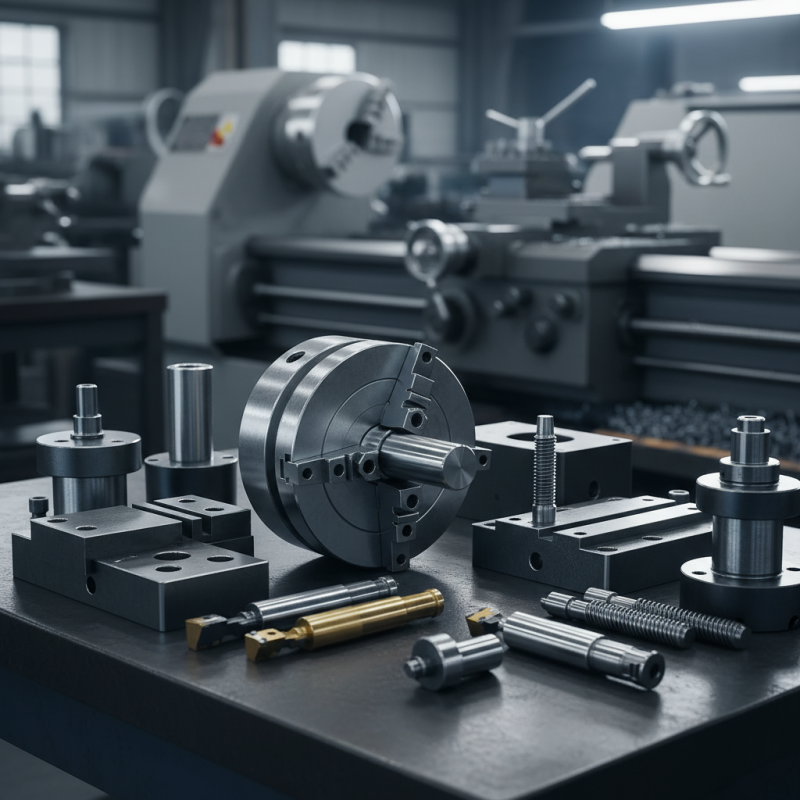

In the realm of precision engineering, "lathe machine parts" play a pivotal role. These components are crucial for the operation of modern lathes, which are essential in various industries such as automotive and aerospace. According to a recent industry report by Global Market Insights, the lathe machine market is expected to reach $5 billion by 2026, highlighting the growing demand for precision in manufacturing.

Renowned expert Dr. Andrew Smith emphasizes, "Quality lathe machine parts are vital for achieving the highest level of accuracy." This statement underlines the importance of selecting the right components to enhance performance. However, many engineers often overlook the impact of wear and tear on these parts. Regular maintenance is crucial. Even minor degradation can lead to significant errors in production.

As precision in engineering becomes increasingly critical, the focus should intensify on the integrity of lathe machine parts. Investing in high-quality components may pose a financial challenge, yet it is essential for ensuring long-term operational efficiency. Balancing cost and quality is an ongoing struggle that demands careful consideration.

Understanding the Basics of Lathe Machines in Precision Engineering

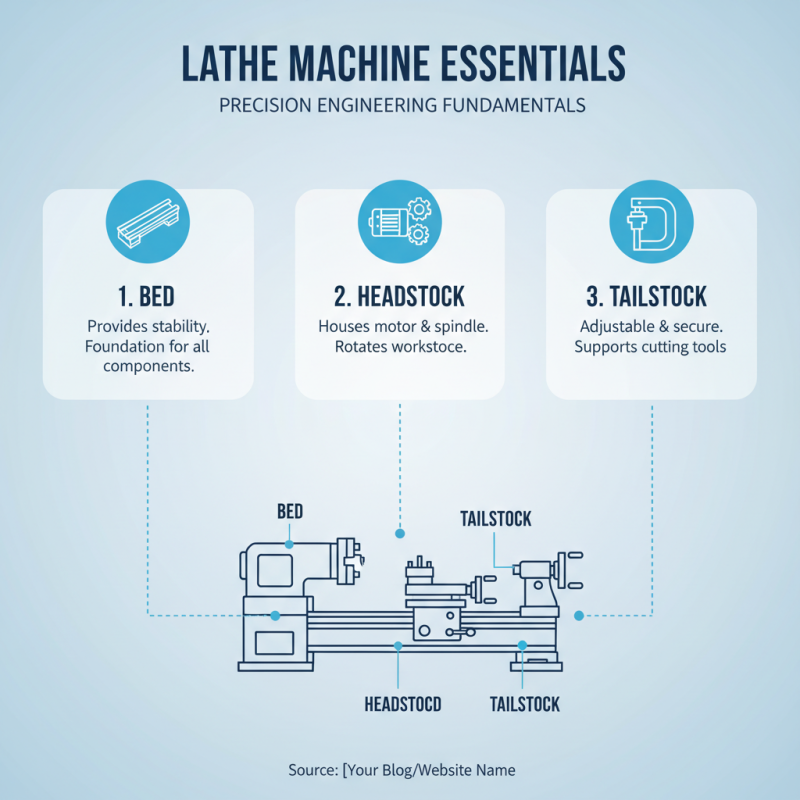

Lathe machines play a crucial role in precision engineering. They shape materials into desired forms with accuracy. Understanding their basic components is essential for effective use. The three main parts of a lathe machine include the bed, headstock, and tailstock. The bed offers stability while the headstock houses the motor and spindle. The tailstock is adjustable and holds tools securely.

Tip: Regular maintenance of these components ensures longevity. Check for wear and tear frequently. This habit can prevent unexpected breakdowns.

Precision machining relies heavily on tool selection. Each tool serves a specific purpose, from cutting to sanding. A dull tool can lead to inaccuracies. Always assess the sharpness before starting a project. Having a range of tools is beneficial, too.

Tip: Invest in quality tools. They might be costlier upfront but will be more efficient in the long run. Don’t overlook the importance of proper alignment. Misalignment can result in defects and wasted material. Always take time to set up correctly.

Key Components of a Lathe Machine and Their Functions

The lathe machine is a fundamental tool in precision engineering. Understanding its key components is crucial for achieving quality results.

The bed provides stability, ensuring accurate machining. It supports all other parts and absorbs vibrations during operation.

Another vital component is the spindle. It holds the workpiece securely in place while it rotates. A well-functioning spindle influences the precision of the cut.

The tailstock is also essential, offering support and alignment for longer pieces. However, it can sometimes cause misalignment if not properly adjusted.

The carriage houses the cutting tools. It slides along the bed, allowing for intricate movements. Users often face challenges with the drive belt, as wear can affect torque delivery.

Regular maintenance is necessary to keep all parts in working order. Each element plays a role in the overall functionality of the machine.

Reflecting on the setup can reveal areas needing improvement.

The Importance of Precision in Lathe Machine Operations

Precision is critical in lathe machine operations. Each component, from the spindle to the tailstock, must work seamlessly. The alignment of these parts determines the overall outcome of the machining process. Minor errors can lead to significant deviations in the final product, affecting quality and performance. Ensuring each part is calibrated properly is vital, yet often overlooked.

Tips for improving precision include regularly checking your tools and maintaining the machine. Dirty or worn-out components can impact their functionality. Additionally, always use the right settings for each material you work with. Experimenting with feed rates and speeds can yield better results. Even so, don’t hesitate to reevaluate your techniques if you notice consistent inaccuracies.

Another common mistake is neglecting to measure frequently during the machining process. It’s tempting to rush through tasks, but taking time to measure can save hours later on. Small adjustments during production are far easier than making corrections to finished products. Pay attention to detail. Investing in precision not only enhances quality but also boosts your reputation as a skilled machinist. Remember, perfection is a journey, not a destination.

Top Lathe Machine Parts Essential Components for Precision Engineering

| Component | Function | Material | Importance in Precision |

|---|---|---|---|

| Spindle | Holds and rotates the workpiece | High-carbon steel | Critical for maintaining axial alignment |

| Tool Post | Secures the cutting tool | Aluminum alloy | Ensures precise tool positioning |

| Tailstock | Supports the opposite end of the workpiece | Cast iron | Stabilizes work for better accuracy |

| Carriage | Moves the tool across the workpiece | Steel | Essential for precise linear movements |

| Lead Screw | Controls the lateral movement of the carriage | Brass | Determines accuracy of movements |

Maintenance Tips for Essential Lathe Machine Parts

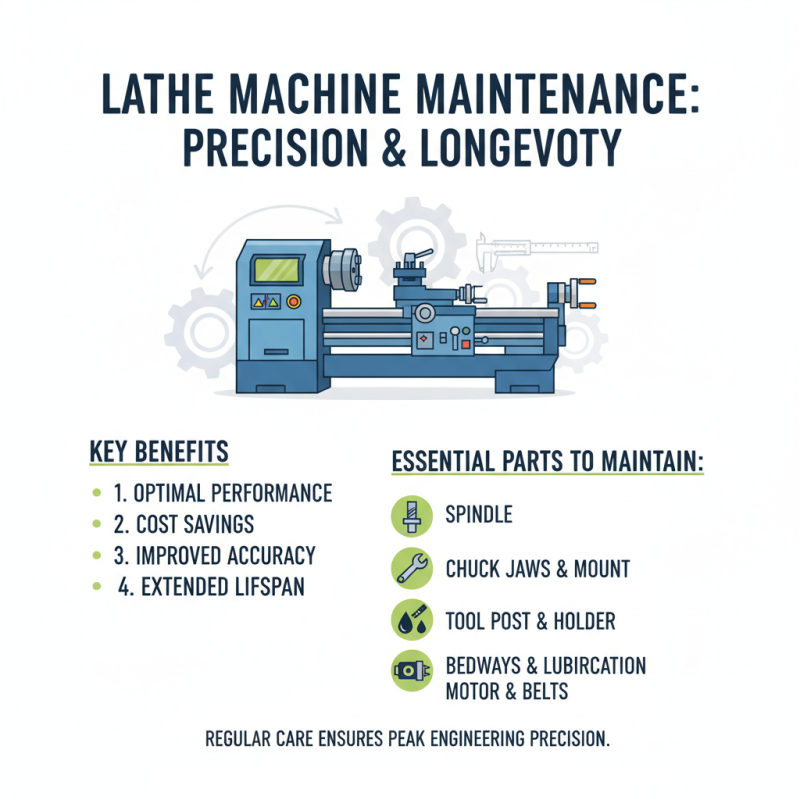

Lathe machines are crucial for precision engineering. Maintaining their essential parts is vital for optimal performance. Regular maintenance can save costs and improve accuracy.

To keep your lathe running smoothly, check the spindle regularly. A worn spindle can lead to vibrations. These vibrations affect the quality of your work. Ensure it is properly lubricated with the right oil.

The bed should also be inspected often. Look for any signs of wear or chips. These imperfections can cause inaccuracies in your projects. Additionally, clean the bed routinely to prevent debris buildup.

Lastly, keep an eye on the tailstock. Adjust it correctly to ensure proper alignment. Misalignment can lead to significant errors. Remember to consult the user manual if you’re unsure about any procedures. Each component needs attention for the best results.

Upgrading and Customizing Lathe Machine Components for Efficiency

Upgrading lathe machine components can greatly enhance efficiency. When considering improvements, focus on precision components. Tools like high-quality chucks and cutting tools can make a significant difference. These parts allow better grip and stability, leading to superior accuracy in machining operations.

Customizing components like tailstocks and tool posts also proves beneficial. Adjustable features help in achieving the required tool position. However, choosing the right materials for upgrades can be tricky. Sometimes, what seems best on paper does not perform as expected in real applications. Testing is essential, as results may vary.

Consider also the importance of regular maintenance. Even upgraded components need care to perform optimally. Dust and debris can accumulate, causing parts to wear out faster. Seek methods to streamline cleaning and maintenance routines. Small adjustments in these areas may lead to significant gains in overall productivity.

Top Lathe Machine Parts: Essential Components for Precision Engineering

Related Posts

-

2025 Top 5 Essential Lathe Machine Parts You Need for Optimal Performance

-

2025 Top 10 CNC Machines: Unveiling the Future of Precision Engineering and Automation

-

How to Choose the Right CNC Parts for Your Machining Projects

-

What is VMC Machine and How Does it Work?

-

What is a CNC Mill and How Does It Work?

-

Top 10 Benefits of Using Prototype Machined Parts for Your Project Success