10 Essential Tips for Operating a Lathe Machine Efficiently?

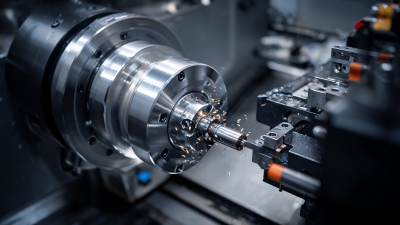

Operating a lathe machine efficiently requires skill and attention to detail. The lathe machine is an essential tool in many workshops. It shapes materials by rotating them against cutting tools. This process, while effective, can lead to mistakes if not approached carefully.

Many operators struggle with basic adjustments. Proper setup is vital but often overlooked. A small error can result in wasted materials and time. Additionally, understanding the machine's speed and feeds is crucial for optimal results. Taking a moment to reflect on these aspects can prevent frustration.

Moreover, safety should always be a priority. Even experienced operators must remain aware of their surroundings. A moment of distraction can lead to accidents. Improving efficiency is an ongoing journey that requires constant learning and adaptation. By embracing these challenges, operators can master the lathe machine and produce quality work.

Understanding the Basics of Lathe Machine Operation

Operating a lathe machine requires a clear understanding of its basic components and functions. The lathe holds the workpiece securely while the cutting tool shapes it. Knowing how to adjust the speed and feed rate is crucial. Each material may require different settings. A wood piece will behave differently than metal.

Proper safety measures are essential. Always wear safety goggles and keep your hands clear of the rotating parts. Many beginners neglect these precautions. It's vital to maintain focus on the workpiece. Distractions can lead to accidents or mistakes. Regularly inspecting the machine for any wear and tear is equally important.

Mistakes are part of the learning process. Occasionally, a part may not turn out as expected. This can be frustrating but offers valuable lessons. Analyzing what went wrong helps improve future operations. Reflecting on those errors fosters growth and skill enhancement. Embrace the journey of mastering lathe operations.

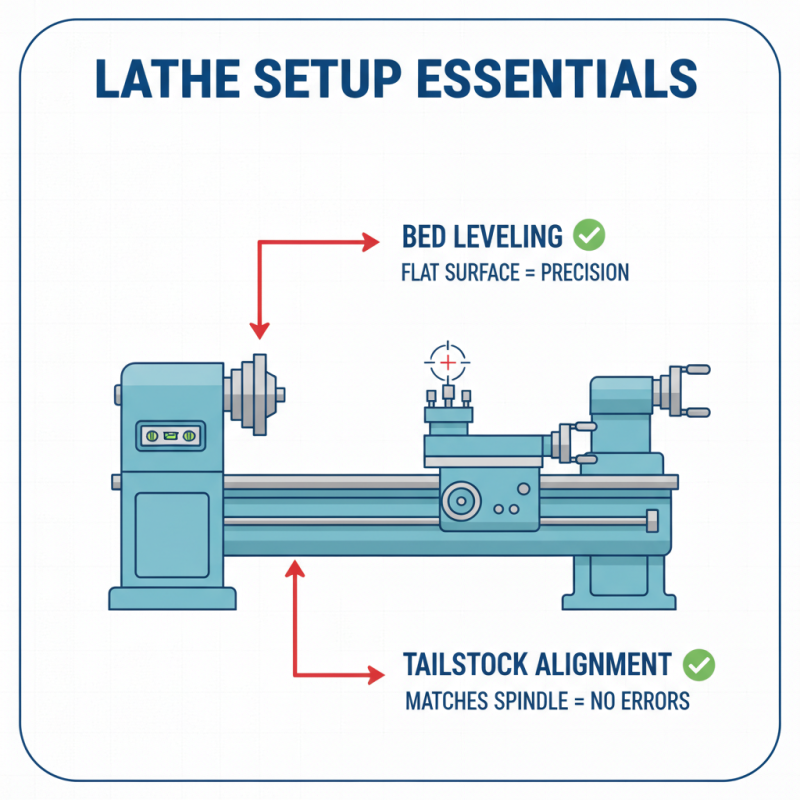

Setting Up the Lathe: Key Components and Adjustments

Setting up a lathe machine requires careful attention to key components. Start by ensuring that the bed is level. A flat surface helps in achieving precision. Adjust the tailstock and ensure it aligns perfectly with the spindle. Misalignment can lead to significant errors in your workpiece.

Check the tool holder for proper fit. It should hold tools securely without wobble. Loose tools can compromise the quality of your cuts. Pay attention to spindle speed settings as well. Too high a speed can result in overheating, while too low may cause chatter. You may need to experiment to find the optimal speed for different materials.

Having the right cutting tool is just as important. Dull tools can make operations difficult. You may not achieve the desired finish. Regularly inspect and sharpen your tools for the best results. Consider your setup regularly, as even a small adjustment can have a big impact on your lathe's performance.

Selecting the Right Materials and Tools for Lathe Work

Selecting the right materials and tools for lathe work is crucial for efficiency and precision. Common materials include metals, woods, and plastics. Each material requires specific tools to achieve desired results. For instance, choosing high-speed steel (HSS) or carbide tools can drastically affect performance. According to a report from the Manufacturing Technologies Association, the right tool can increase cutting speed by 25%.

Tool wear is another crucial factor. It influences the finish quality and precision. Regularly monitoring tool conditions can prevent issues. Experts suggest that a worn tool can lead to dimensional inaccuracies. These can cost time and materials. Lathe operators should inspect their tools routinely. It's not just about selecting tools; knowing when to replace them is vital.

Material choice also impacts machine settings. Machinists often face challenges with varying densities and hardness. A softer material may require higher speeds, while harder materials need more torque. According to a survey by the National Institute of Standards and Technology, improper settings can reduce productivity by 30%. Operators must adjust their techniques based on material properties. When overlooked, this aspect can cause unnecessary setbacks.

Implementing Safety Measures During Lathe Operation

Operating a lathe machine requires a strong focus on safety. Before starting, always wear appropriate personal protective equipment (PPE). Safety glasses prevent eye injuries from flying debris. Hearing protection keeps noise levels manageable. Ensure that long hair and loose clothing are secured. This reduces the risk of entanglement in the machinery.

Take time to examine the lathe before use. Inspect the work area for potential hazards. Clean up any clutter or spills that may cause accidents. Familiarize yourself with the machine's emergency stop features. A quick response can prevent serious injuries. Maintain a safe distance from moving parts. Remember, it only takes a moment for an accident to happen.

Practice good ergonomic habits. Position your body correctly while working. This avoids strain and reduces fatigue. Pay attention to your surroundings and stay alert. Sometimes, distractions can lead to mistakes. Reflect on past experiences to improve your safety measures. Identify any close calls and address their causes. Safety is an ongoing process that requires vigilance and commitment.

Maintaining Your Lathe for Optimal Performance and Longevity

Maintaining your lathe machine is crucial for ensuring optimal performance and longevity. Regular maintenance not only enhances precision but also reduces downtime. According to industry reports, a well-maintained lathe can increase productivity by 15-20%. This highlights the importance of consistent upkeep.

Inspect the lathe regularly for wear and tear. Pay attention to the drive belt and spindle bearings, as they are common failure points. Replace worn components promptly to avoid costly breakdowns. Clean the machine after each use. Chips and debris can affect accuracy and lead to more significant issues over time.

Lubrication is key. Use the manufacturer's recommended oils to reduce friction and wear. A well-lubricated lathe operates smoother and lasts longer. Remember, though, that over-lubrication can attract more dust. This interplay of maintenance requires careful observation and adjustment. Make it a habit to document maintenance activities. This will help identify patterns or recurring problems. Overall, thoughtful care of your lathe can significantly prolong its life and enhance performance.

Related Posts

-

Exploring the Future of Precision Engineering with CNC Turning Machines

-

2025 How to Choose the Best CNC Turning Center for Your Manufacturing Needs

-

How to Choose the Right CNC Turning Center for Your Machining Needs

-

Ultimate Guide to CNC Turning Machine Benefits and Applications for Beginners

-

Top 10 CNC Lathe Machines for Precision Engineering in 2023

-

What is a CNC Mill and How Does It Work?