2025 How to Choose the Best CNC Turning Center for Your Manufacturing Needs

As manufacturing technology continues to evolve, the demand for precision and efficiency has never been higher. In 2025, choosing the right CNC turning center becomes crucial for businesses aiming to optimize their production processes. According to a recent industry report by Market Research Future, the global CNC turning centers market is projected to reach $5 billion by 2025, showcasing a compound annual growth rate of 8.7%. This growth is fueled by the increasing adoption of automation and precision machining across various sectors, including aerospace, automotive, and metalworking.

Industry expert Dr. Emily Chen, a leading figure in CNC technology, states, “Selecting the appropriate CNC turning center can significantly enhance manufacturing efficiency and product quality.” With advancements in technology, manufacturers now have access to a variety of CNC turning center options that can cater to specific production needs. Factors such as spindle speed, tooling capabilities, and software integration play critical roles in this selection process. As businesses navigate their options, understanding the latest trends and technologies in CNC turning centers will be vital for maintaining a competitive edge in the marketplace.

Key Features to Consider When Selecting a CNC Turning Center

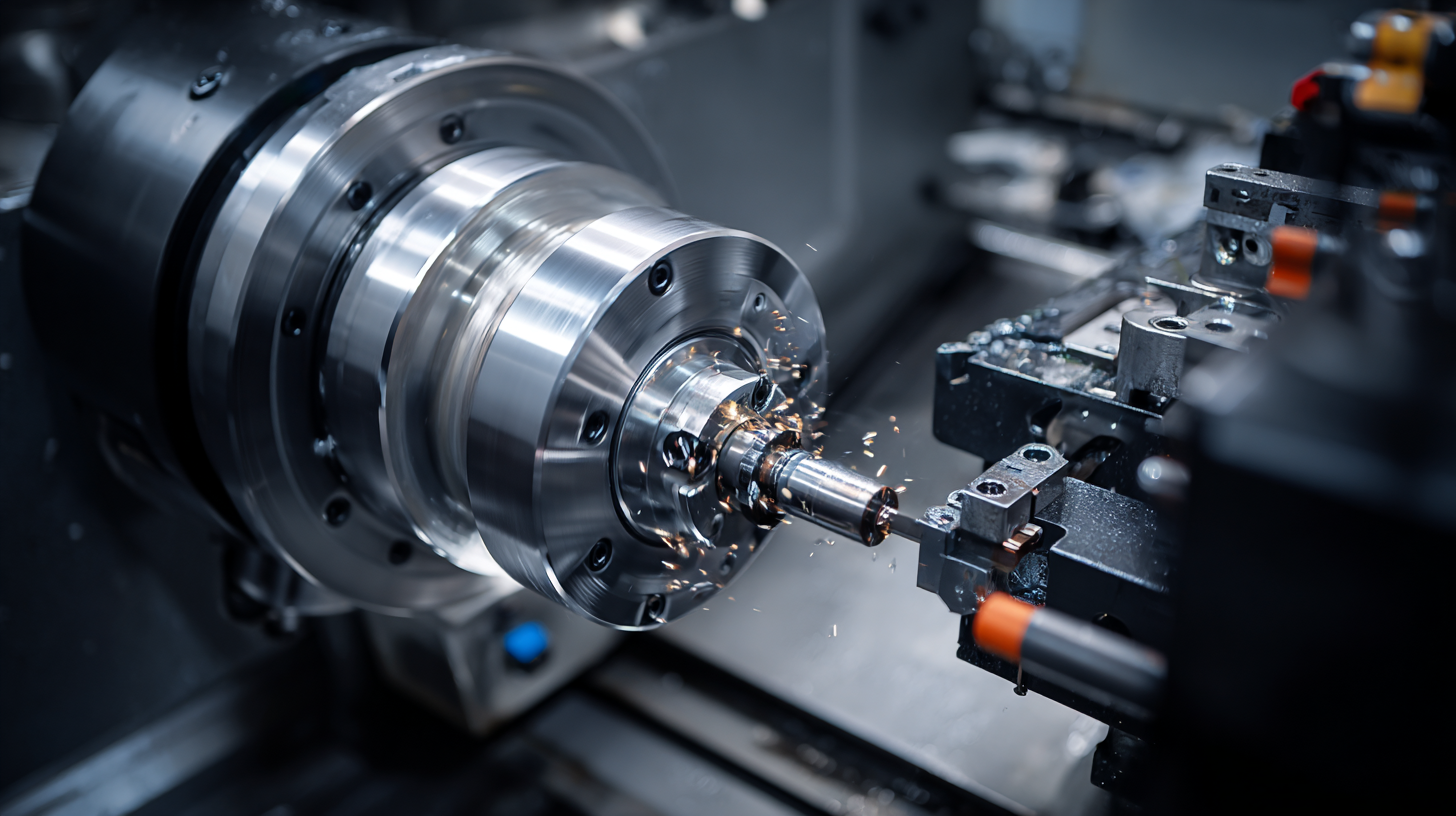

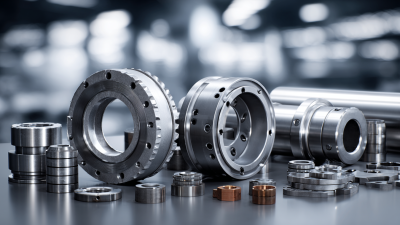

When selecting a CNC turning center for your manufacturing needs, it is essential to consider several key features that can significantly impact productivity and precision. One of the primary factors is the machine's torque and spindle speed, which determines its ability to handle various materials and complex shapes. A turning center with a higher torque allows for better performance on tougher materials, while an optimal spindle speed will ensure quality finishes and reduced cycle times. Additionally, the size and capacity of the turning center should match your production requirements, including the maximum diameter and length of the workpieces.

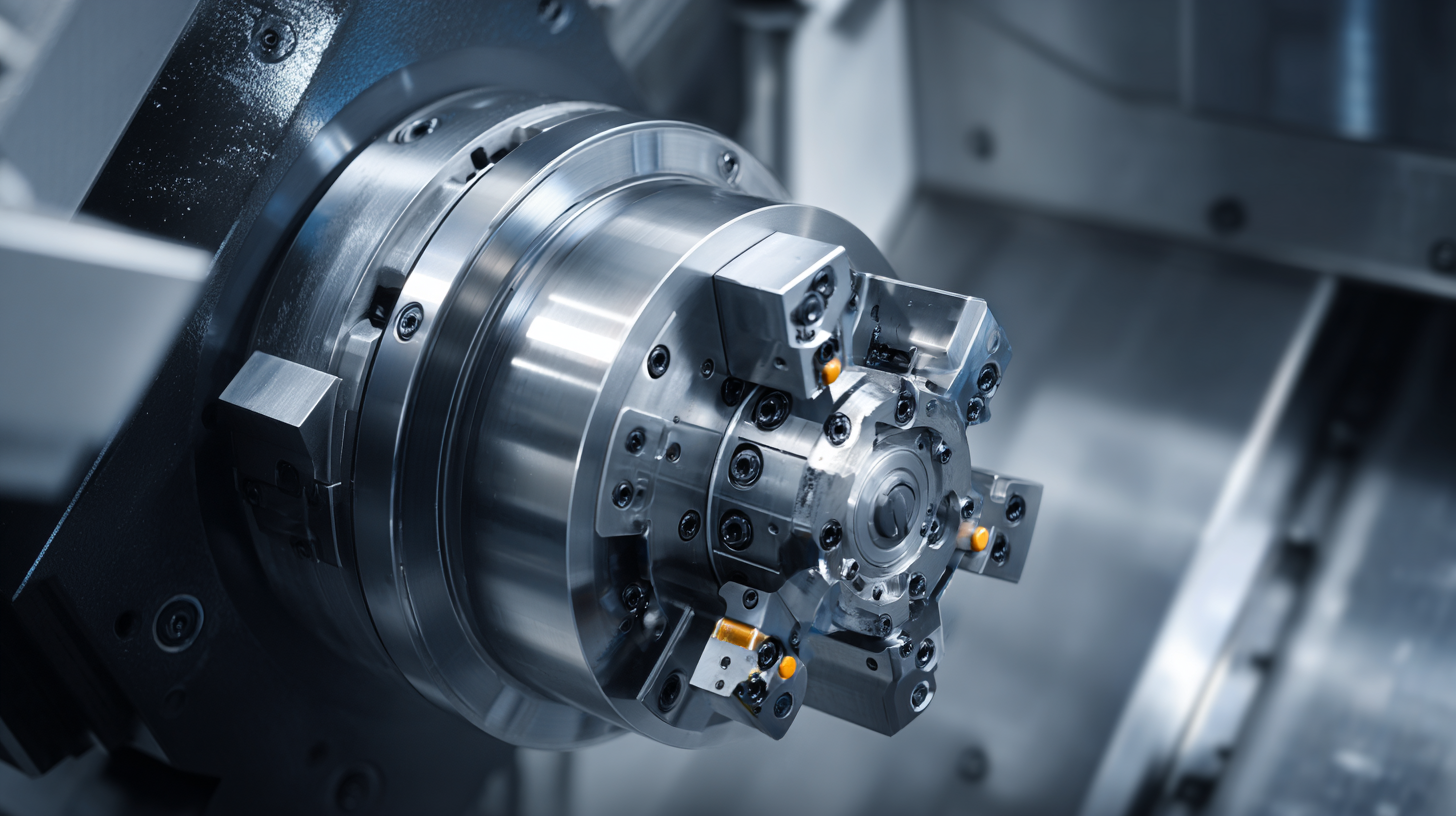

Another important feature to look for is the control system and software capabilities. A user-friendly interface and advanced programming options can greatly enhance operational efficiency. It's crucial to ensure that the CNC turning center is compatible with your existing systems and can support the necessary CAD/CAM software. Furthermore, consider the tool changer capacity and type, as this will impact the machine's versatility and speed in executing various tasks. By focusing on these features, you can select a CNC turning center that aligns perfectly with your specific manufacturing needs.

Understanding Different Types of CNC Turning Centers Available

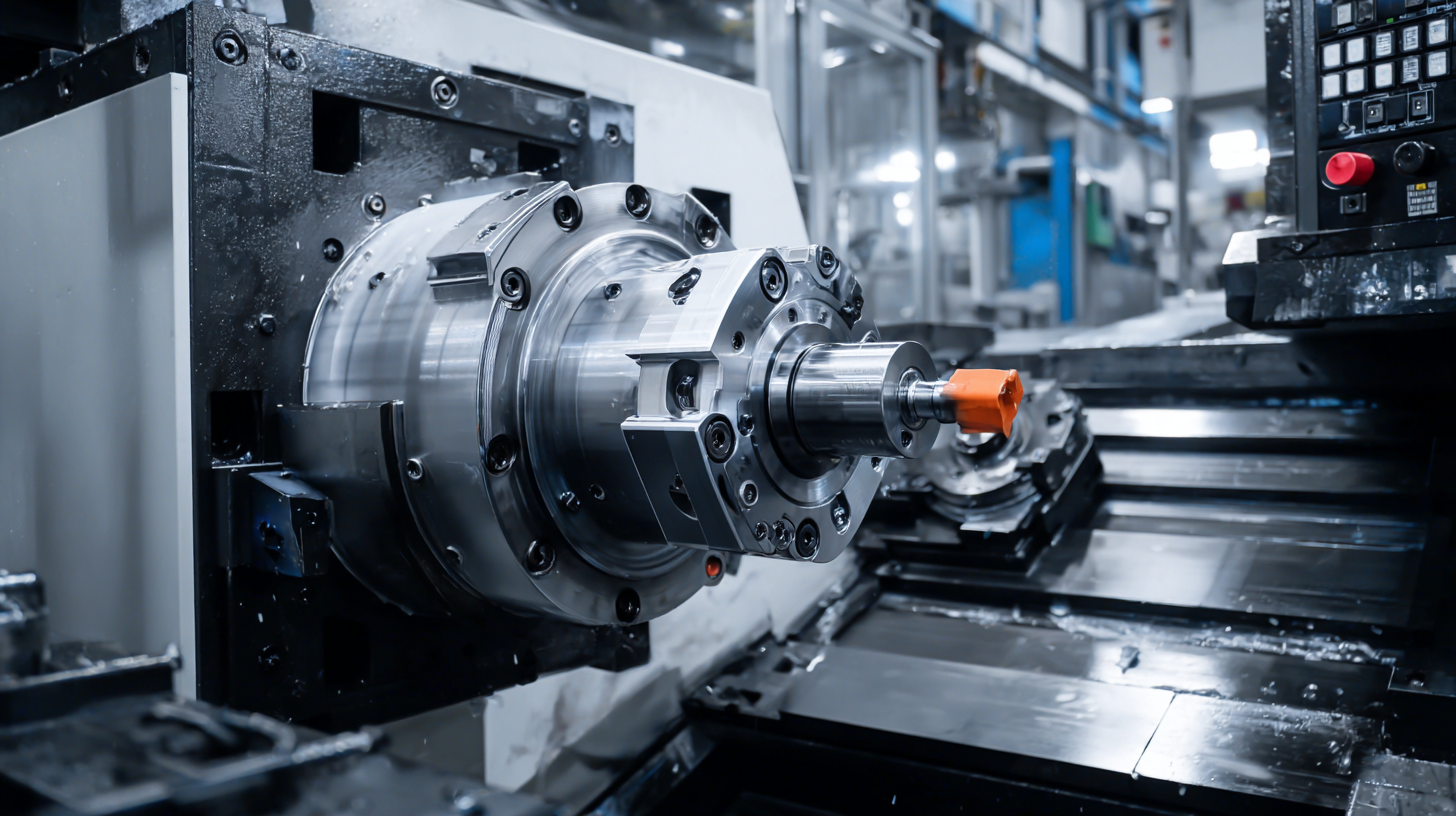

When selecting a CNC turning center for your manufacturing needs, it’s essential to understand the various types available in the market. CNC turning centers can be broadly categorized into two types: horizontal and vertical. Horizontal CNC turning centers are typically used for larger workpieces, providing better stability and ease of accessibility. On the other hand, vertical CNC turning centers are suitable for smaller parts and often occupy less floor space, making them ideal for facilities with limited room.

Tips: Consider the size and weight of the components you will produce when choosing between horizontal and vertical turning centers. If flexibility and quick setup are crucial, look for a center that offers quick-change tools and adaptive work holding options.

Another vital aspect to consider is the control system. Some CNC turning centers come with advanced control technology offering features like programmable logic control (PLC) and user-friendly interfaces. These systems can significantly enhance productivity and precision in your machining operations.

Tips: Evaluate your team’s expertise with specific control systems, as a familiar interface can reduce training time and improve efficiency. Ensure that the CNC turning center you choose supports the software and protocols you’re accustomed to utilizing in your workshop.

Evaluating Cost vs. Performance in CNC Turning Machine Selection

When selecting a CNC turning center for your manufacturing needs, evaluating the balance between cost and performance is crucial. According to the 2022 Global CNC Machine Market Report, the market is projected to grow at a CAGR of 5.8% from 2023 to 2028. This increase in demand emphasizes the need for businesses to invest wisely in CNC machinery that not only fits within budget constraints but also meets production efficiency requirements.

To make a sound choice, consider the total cost of ownership (TCO) which includes initial purchase price, maintenance, and operational costs. A report by Deloitte highlights that high-performance CNC machines, while potentially more expensive upfront, often result in lower operational costs due to increased reliability and efficiency. It's essential to analyze your specific production processes to determine which features are necessary, such as spindle speeds and tooling versatility, to ensure you get the best return on investment.

**Tips:** Focus on selecting a CNC turning center that offers scalability. As your production demands grow, your machinery should be capable of adapting to increased workloads without a complete overhaul. Additionally, invest in training for your operators; reports indicate that well-trained personnel can enhance machine performance by up to 20%. Finally, always assess the availability of customer support and spare parts when choosing a supplier to minimize downtime in production.

Assessing Space and Setup Requirements for Your Turning Center

When selecting a CNC turning center, understanding the spatial and setup requirements is crucial to optimize efficiency and productivity. Manufacturers must first evaluate the dimensions of the turning center itself. This includes checking the footprint and ensuring that there is adequate clearance around the machine for maintenance and operation. Additionally, the configuration of the production floor must accommodate not just the turning center but also ancillary equipment, such as tool changers and workstations.

Another key aspect is the infrastructure supporting the CNC turning center. This encompasses the availability of power supply, air requirements, and cooling systems, which are essential for the optimal performance of high-speed machinery. Manufacturers should also consider the accessibility of the machine for loading and unloading materials, which plays a significant role in overall workflow efficiency. By carefully assessing these factors, companies can ensure a seamless integration of the CNC turning center within their existing operations, ultimately leading to enhanced productivity and reduced downtime.

Importance of After-Sales Support and Training for CNC Machines

When investing in a CNC turning center, the importance of after-sales support and training cannot be overstated. A comprehensive report by MarketsandMarkets indicates that the global CNC machine market is expected to grow from $81.56 billion in 2020 to $117.37 billion by 2025, highlighting the increasing reliance on advanced machinery. However, having the machinery alone is not enough; effective after-sales support is essential to maximize operational efficiency and minimize downtime. Manufacturers with robust after-sales services experience up to 20% less machine downtime, allowing for increased productivity.

Moreover, adequate training for staff ensures that the technology is utilized to its fullest potential. According to a study by Deloitte, companies that invest in employee skill development enjoy a 34% higher retention rate, which significantly contributes to better performance and quality output. Training programs not only encompass machine operation but also maintenance, ensuring that operators are well-equipped to handle issues proactively. Ultimately, the right blend of after-sales support and comprehensive training can lead to a more sustainable and profitable manufacturing environment, making it a priority for businesses when choosing their CNC turning center.

Related Posts

-

Exploring the Future of Precision Engineering with CNC Turning Machines

-

Unlocking Innovation: The Vital Role of Machined Parts in Modern Manufacturing Advances

-

2025 Top 10 CNC Machines: Unveiling the Future of Precision Engineering and Automation

-

The Future of Brass CNC Machining Innovations and Trends in Precision Engineering

-

2025 Top 5 Essential Lathe Machine Parts You Need for Optimal Performance

-

Exploring the Future of Manufacturing: How CNC Machine Tools Revolutionize Precision Engineering