Unlocking Innovation: The Vital Role of Machined Parts in Modern Manufacturing Advances

In today's rapidly evolving manufacturing landscape, machined parts play a pivotal role in driving innovation and efficiency across various industries. According to a report by MarketsandMarkets, the global machined components market is projected to reach USD 1.5 trillion by 2025, reflecting a compound annual growth rate (CAGR) of 7.9%. This growth underscores the critical importance of machined parts in modern production processes, which enable manufacturers to enhance precision, optimize performance, and reduce production costs. As industries increasingly adopt advanced technologies like automation and additive manufacturing, the demand for high-quality machined parts has surged, demonstrating their essential role in supporting innovative solutions and meeting the challenges of the future. In this context, understanding the significance of machined parts is crucial for businesses aiming to stay competitive and meet the ever-evolving demands of the market.

The Evolution of Machined Parts in Modern Manufacturing Practices

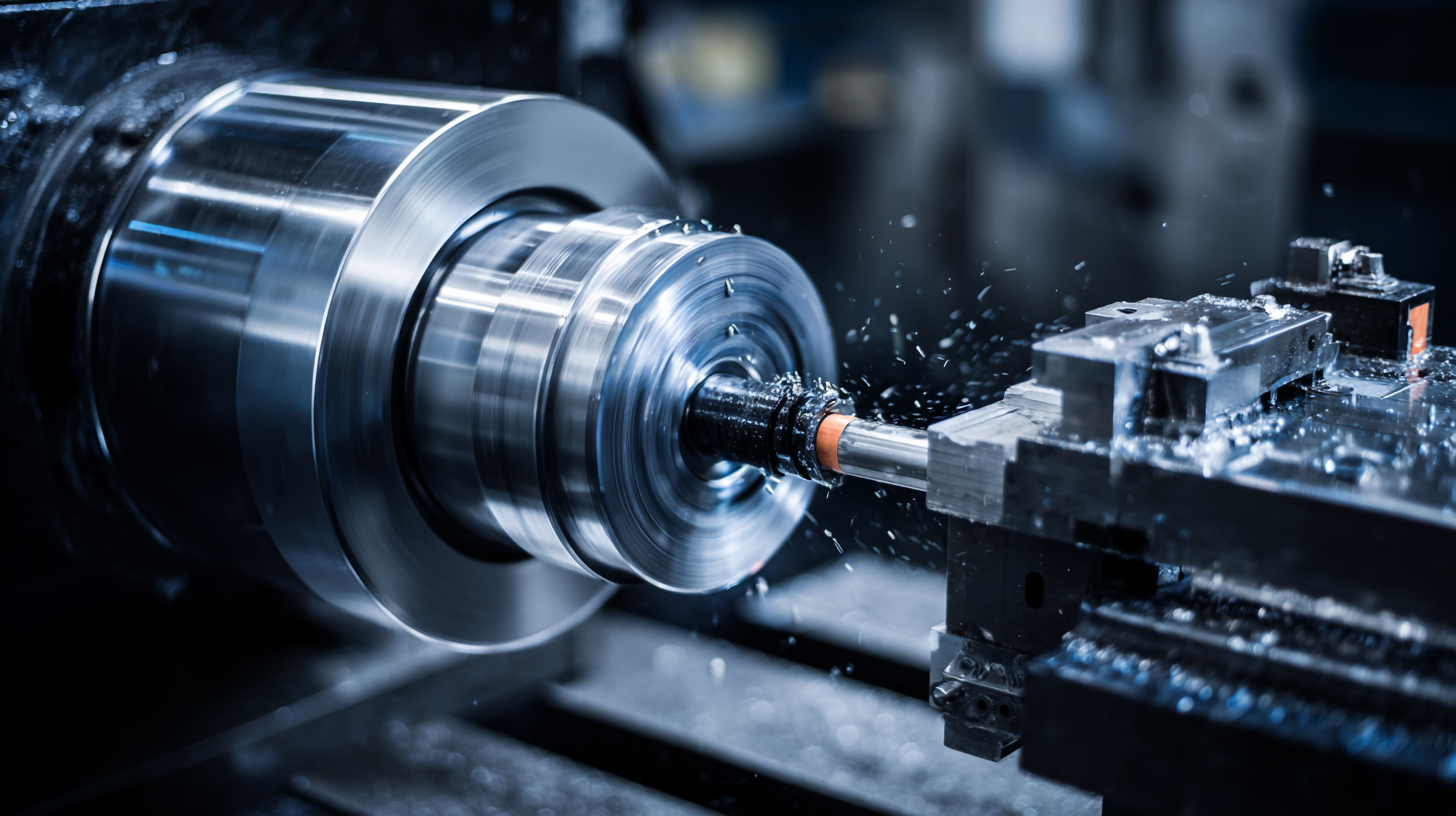

The evolution of machined parts in modern manufacturing practices has been driven by the adoption of advanced digital technologies, which have significantly enhanced productivity across various industries. These innovations, including CNC machining, automated wire-cutting, and machine vision systems, are transforming traditional manufacturing processes into highly efficient, precision-focused operations. Companies are leveraging state-of-the-art techniques to produce components with unparalleled accuracy and consistency, addressing the growing demand for high-quality products in competitive markets.

As industries strive for sustainability and efficiency, advancements in machining technology, such as low-pressure injection molding, are redefining manufacturing standards. These innovations not only promote environmentally-friendly practices but also ensure that manufacturers can meet the rigorous demands of modern consumers. Furthermore, the integration of AI and real-time analytics into manufacturing workflows is enhancing decision-making processes and improving overall operational efficiency. This ongoing evolution signifies a crucial shift in how the manufacturing sector approaches production, ultimately paving the way for future innovations that will further revolutionize the field.

Unlocking Innovation: The Vital Role of Machined Parts in Modern Manufacturing Advances

Key Statistics Reflecting the Impact of Machined Parts on Efficiency and Quality

Machined parts play an essential role in enhancing efficiency and quality within modern manufacturing processes. According to a report by the National Association of Manufacturers (NAM), companies that invest in advanced machining technologies can experience up to a 25% increase in operational efficiency. This substantial improvement is attributed to precision and reduced waste, showcasing how machined components are critical in meeting the demands of a competitive market.

Machined parts play an essential role in enhancing efficiency and quality within modern manufacturing processes. According to a report by the National Association of Manufacturers (NAM), companies that invest in advanced machining technologies can experience up to a 25% increase in operational efficiency. This substantial improvement is attributed to precision and reduced waste, showcasing how machined components are critical in meeting the demands of a competitive market.

Moreover, in a recent industry analysis conducted by Deloitte, it was found that 70% of manufacturers reported improved product quality after integrating advanced machining methods into their workflows. This statistic underscores the impact of precision machining in reducing error rates and ensuring tighter tolerances—key factors that lead to higher customer satisfaction. As the manufacturing landscape continues to evolve, the data clearly indicates that machined parts are vital not only for operational improvements but also for achieving superior product standards.

Innovative Materials and Technologies Driving Machined Part Advancements

In the rapidly evolving landscape of modern manufacturing, innovative materials and technologies are pivotal in driving advances in machined parts. According to a report by the American Manufacturing Association, the machinable materials market is projected to reach $150 billion by 2025, underscoring the crucial role that advanced materials play in enhancing productivity and efficiency. High-performance alloys, such as titanium and nickel-based superalloys, are increasingly utilized for their superior strength-to-weight ratios, enabling the production of lightweight components without compromising structural integrity.

Moreover, emerging technologies such as additive manufacturing and CNC machining are revolutionizing how machined parts are produced. A study by Deloitte estimates that the adoption of these technologies could improve productivity by as much as 40% in some sectors within the next five years. For instance, 3D printing allows for complex geometries that traditional machining methods cannot achieve, resulting in reduced material waste and shorter lead times. As industries continuously seek competitive advantages, the integration of innovative materials and cutting-edge machining technologies will undoubtedly shape the future of manufacturing, ultimately fostering unprecedented levels of innovation and efficiency.

Case Studies: Successful Integration of Machined Parts in Industry 4.0 Initiatives

In the realm of Industry 4.0, the integration of machined parts has proven to be a game changer for various sectors. One notable case study is the automotive industry, where companies are utilizing advanced machining techniques to produce lighter and more durable components. By employing additive manufacturing alongside traditional machining, manufacturers can optimize design complexity while reducing material waste. This synergy not only enhances product performance but also accelerates the production process, allowing for a more agile response to market demands.

Another compelling example can be found in the aerospace sector, where precision and reliability are paramount. Leading aerospace companies are integrating machined parts with IoT technology to enable predictive maintenance of engines and components. By equipping machined parts with sensors, manufacturers can gather real-time data, streamlining operations and minimizing downtime. This proactive approach not only improves operational efficiency but also significantly enhances safety, positioning these companies as frontrunners in the adoption of smart manufacturing practices.

Future Trends: The Role of Machined Parts in Sustainable Manufacturing Solutions

In recent years, the manufacturing industry has increasingly recognized the importance of sustainability, and machined parts play a critical role in this transition. When designed with eco-friendly materials and advanced manufacturing techniques, machined components can significantly reduce waste and energy consumption. By optimizing machining processes, manufacturers can achieve higher precision while minimizing the environmental impact, thereby aligning production methods with sustainable practices.

Future trends indicate a growing reliance on additive manufacturing and computer numerical control (CNC) technologies to enhance the efficiency of machined parts. These innovations allow for the creation of complex geometries that traditional methods cannot achieve, leading to lighter and more functional components. As industries strive for circular economy initiatives, the ability to recycle and remanufacture machined parts will further contribute to sustainability efforts. This shift not only supports environmental goals but also drives economic benefits, creating a compelling case for integrating advanced machined parts into modern manufacturing solutions.

Related Posts

-

Exploring the Future of Precision Engineering with CNC Turning Machines

-

Discover the Best Techniques for CNC Turning Parts Manufacturing Efficiency

-

Exploring the Future of Manufacturing: How CNC Machine Tools Revolutionize Precision Engineering

-

Understanding the Benefits of Large Part CNC Machining for Precision Manufacturing