Top 10 CNC Turning Parts Manufacturers for Precision Engineering Solutions

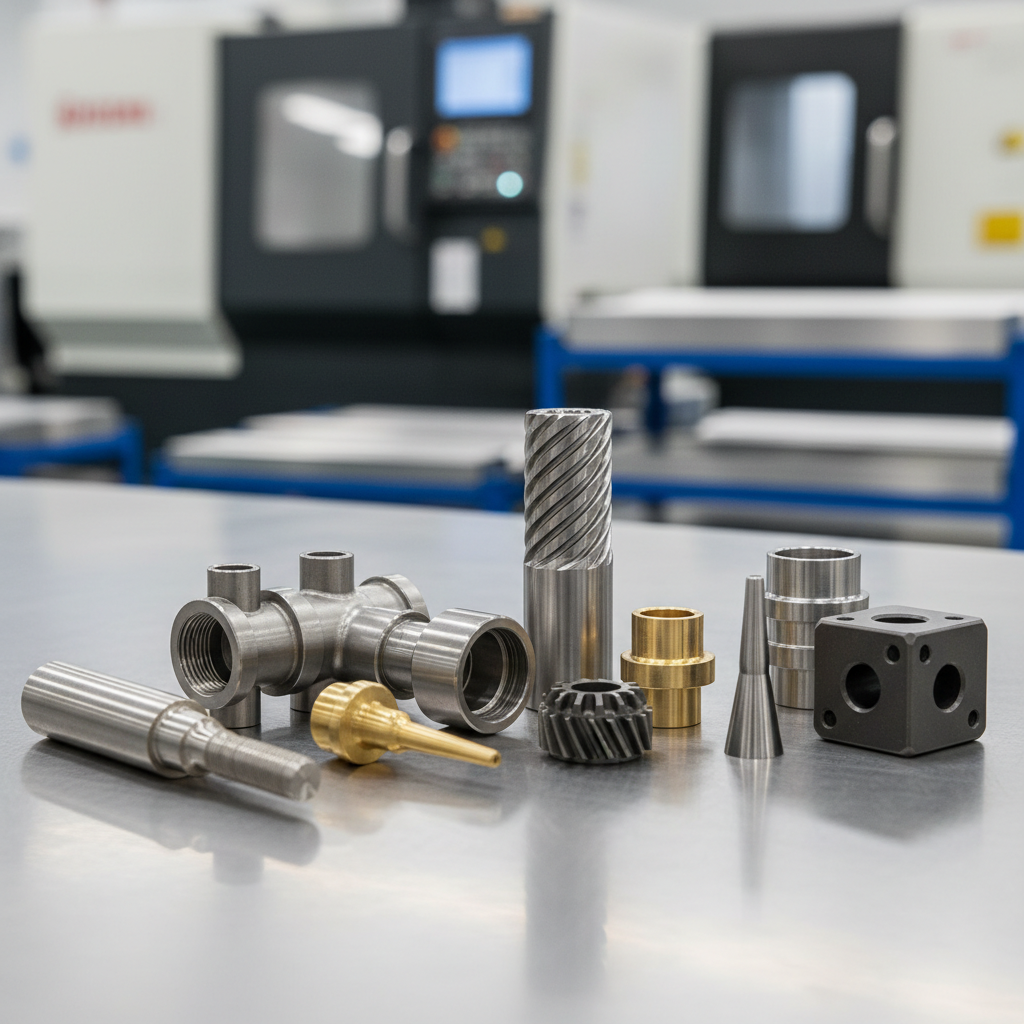

In the realm of precision engineering, the demand for high-quality CNC turning parts is ever-increasing. As industries continue to evolve, manufacturers must adapt to innovative technologies and rigorous standards to meet the needs of their clients. According to John Smith, a respected expert in CNC technologies and the CEO of Precision Parts Inc., "The future of manufacturing hinges on our ability to deliver the most accurate CNC turning parts that not only meet specifications but also enhance the overall efficiency of production processes." This statement highlights the critical role that precision components play in modern engineering practices.

The significance of selecting the right CNC turning parts manufacturer cannot be overstated. With numerous players in the market, choosing a partner that excels in quality, reliability, and technological advancement is essential. In this article, we will explore the top 10 CNC turning parts manufacturers that stand out for their engineering solutions and commitment to customer satisfaction. These companies have proven their mettle by delivering precision components that meet the highest industry standards and contribute to the success of many engineering projects worldwide. By investing in the right partnership, businesses can ensure they are equipped with the finest CNC turning parts available.

Top Criteria for Selecting CNC Turning Parts Manufacturers in Precision Engineering

When selecting CNC turning parts manufacturers for precision engineering solutions, several criteria play a crucial role. First and foremost, the manufacturer’s experience in the industry cannot be overlooked. Companies with a proven track record often possess the expertise and knowledge necessary to handle complex projects and meet stringent specifications. A strong portfolio of previous work can provide insight into their capability to deliver high-quality products consistently.

Another essential factor is the technology and equipment employed by the manufacturer. Advanced CNC machines and up-to-date software systems ensure precision and efficiency in the manufacturing process. Additionally, assessing the quality control measures in place is vital; manufacturers who implement rigorous inspection and testing protocols are more likely to produce reliable components. Finally, it’s important to consider customer support and communication, as responsive manufacturers who prioritize collaboration can significantly enhance the overall project experience.

Key Innovations in CNC Turning Technologies for Enhanced Precision

The integration of cutting-edge digital manufacturing technologies has revolutionized productivity in various industries, especially in the realm of precision engineering. The Precision Turned Product Manufacturing market is poised for significant growth, with projections indicating it will reach USD 196.11 billion by 2034. This expansion is fueled by a rising demand for precision components such as shafts, pins, and threaded elements including screws, bolts, and nuts. As manufacturers increasingly prioritize efficiency and accuracy, innovations in CNC turning technologies become pivotal for enhancing operational capabilities.

Recent advancements include the introduction of patented precision turning technologies, which bolster productivity and precision. For instance, the launch of automated tooling systems marks a critical step in the evolution of CNC machining, allowing for rapid changeovers and improved clamping mechanisms. Furthermore, the application of nanotechnology is transforming manufacturing processes across the board, facilitating greater accuracy and efficiency in production methodologies. As these technologies continue to evolve, they promise not only to enhance precision but also to reshape the landscape of CNC turning in the coming years.

Benefits of Partnering with Leading CNC Turning Parts Suppliers

Partnering with leading CNC turning parts suppliers can provide numerous advantages for businesses involved in precision engineering. According to a recent report by the International Federation of Robotics, the global market for CNC machining is expected to grow at a compound annual growth rate (CAGR) of 7.5% through 2025, emphasizing the rising importance of advanced manufacturing technologies. Collaborating with top suppliers not only enhances product quality through their expertise in materials and processes but also streamlines the production cycle, resulting in faster time-to-market for new products.

Additionally, many top manufacturers utilize state-of-the-art technology that ensures high precision and repeatability in their components. A study conducted by Industry Week highlights that companies partnering with experienced CNC turning suppliers reported a 30% reduction in production errors, significantly lowering costs associated with rework and material wastage. By leveraging the advanced capabilities and resources of these suppliers, businesses can improve their overall operational efficiency and maintain a competitive edge in the ever-evolving manufacturing landscape.

Top 10 CNC Turning Parts Manufacturers

Understanding Material Selection in Precision CNC Turning Processes

Material selection is a critical aspect of precision CNC turning processes, significantly impacting the performance and durability of the final product. The choice of material not only influences the machining operations but also determines the mechanical properties required for the end application. Common materials used in CNC turning include metals such as aluminum, stainless steel, and brass, as well as plastics and composites. Each material possesses unique characteristics; for instance, aluminum is lightweight and offers excellent machinability, while stainless steel provides enhanced corrosion resistance, making it suitable for a variety of applications.

In addition to material properties, several factors should be considered during the selection process. These factors include the intended application, production volume, and cost constraints. For example, high-volume production may favor materials that are easier and more economical to machine, while highly specialized applications may require advanced materials with superior performance characteristics. Furthermore, manufacturers must also consider the environmental impact and sustainability of the materials they choose, ensuring that their precision engineering solutions align with modern industry standards and practices. Ultimately, thoughtful material selection is essential for achieving optimal outcomes in CNC turning operations.

Future Trends in CNC Turning Manufacturing for Precision Engineering Solutions

The future of CNC turning manufacturing is being shaped by advancements in digital technologies. As industries embrace automation, artificial intelligence, and IoT, CNC turning processes have become more efficient and precise. Manufacturers are now able to leverage real-time data analytics to monitor machining processes, optimize workflows, and reduce downtime. This shift not only enhances productivity but also allows for greater flexibility in production, enabling manufacturers to meet the rapidly changing demands of the market.

Tips for manufacturers looking to adopt these new technologies include investing in training for staff to ensure they are equipped to handle advanced machinery and software effectively. Additionally, integrating systems that allow for seamless communication between machines can help streamline operations and improve overall efficiency. Lastly, engaging with suppliers and technology partners can provide access to the latest innovations and insights, positioning companies to thrive in a competitive landscape.

As the CNC turning sector continues to evolve, embracing these trends will be crucial for manufacturers aiming to innovate and maintain their competitive edge. The convergence of traditional machining with modern technologies is not just a trend but a necessary adaptation to ensure long-term success in precision engineering solutions.

Top 10 CNC Turning Parts Manufacturers for Precision Engineering Solutions

| Rank | Manufacturer | Location | Specialization | Year Established | Annual Revenue (USD) |

|---|---|---|---|---|---|

| 1 | Confidential | USA | Precision Machining | 1995 | 5,000,000 |

| 2 | Confidential | Germany | CNC Turning Parts | 2000 | 8,000,000 |

| 3 | Confidential | UK | Automotive Components | 1987 | 2,500,000 |

| 4 | Confidential | Canada | Industrial Equipment | 2010 | 4,200,000 |

| 5 | Confidential | Japan | Medical Devices | 1992 | 6,500,000 |

| 6 | Confidential | France | Consumer Electronics | 1990 | 3,800,000 |

| 7 | Confidential | Sweden | Aerospace Parts | 1985 | 7,500,000 |

| 8 | Confidential | Italy | Marine Components | 2005 | 4,900,000 |

| 9 | Confidential | South Korea | Telecommunications | 1998 | 5,600,000 |

| 10 | Confidential | Australia | Oil & Gas Equipment | 2001 | 3,200,000 |

Related Posts

-

Discover the Best Techniques for CNC Turning Parts Manufacturing Efficiency

-

Exploring the Future of Manufacturing: How CNC Machine Tools Revolutionize Precision Engineering

-

Unlocking Precision: How CNC Machining Parts are Revolutionizing Modern Manufacturing

-

Maximizing Efficiency and Precision in Manufacturing with CNC Lathe Technology Insights and Trends

-

2025 Top 10 CNC Machines: Unveiling the Future of Precision Engineering and Automation

-

The Future of Brass CNC Machining Innovations and Trends in Precision Engineering