2025 Top 5 Essential Lathe Machine Parts You Need for Optimal Performance

In the realm of precision engineering, the significance of lathe machine parts cannot be overstated. As manufacturing processes continue to evolve, the demand for high-performance lathe machines has surged, making it essential to equip them with the right parts to ensure optimal functionality. John Smith, a recognized expert in the machining field, aptly noted, "The right lathe machine parts not only enhance efficiency but also prolong the life of the machine."

As we approach 2025, it's crucial for machinists and manufacturers alike to stay informed about which lathe machine parts are essential for peak performance. Not only do these components play a vital role in achieving precision and accuracy, but they also contribute significantly to overall productivity. By understanding the top parts that must be prioritized, operators can make informed decisions that lead to improved operational outcomes.

In this article, we will explore the top five essential lathe machine parts that are a must-have for anyone serious about maximizing their machinery's performance. From tool holders to drive belts, we will delve into the specifics of each component and how they can impact your machining capabilities in the ever-competitive landscape of 2025.

Understanding the Crucial Role of Lathe Machine Parts in Precision Engineering

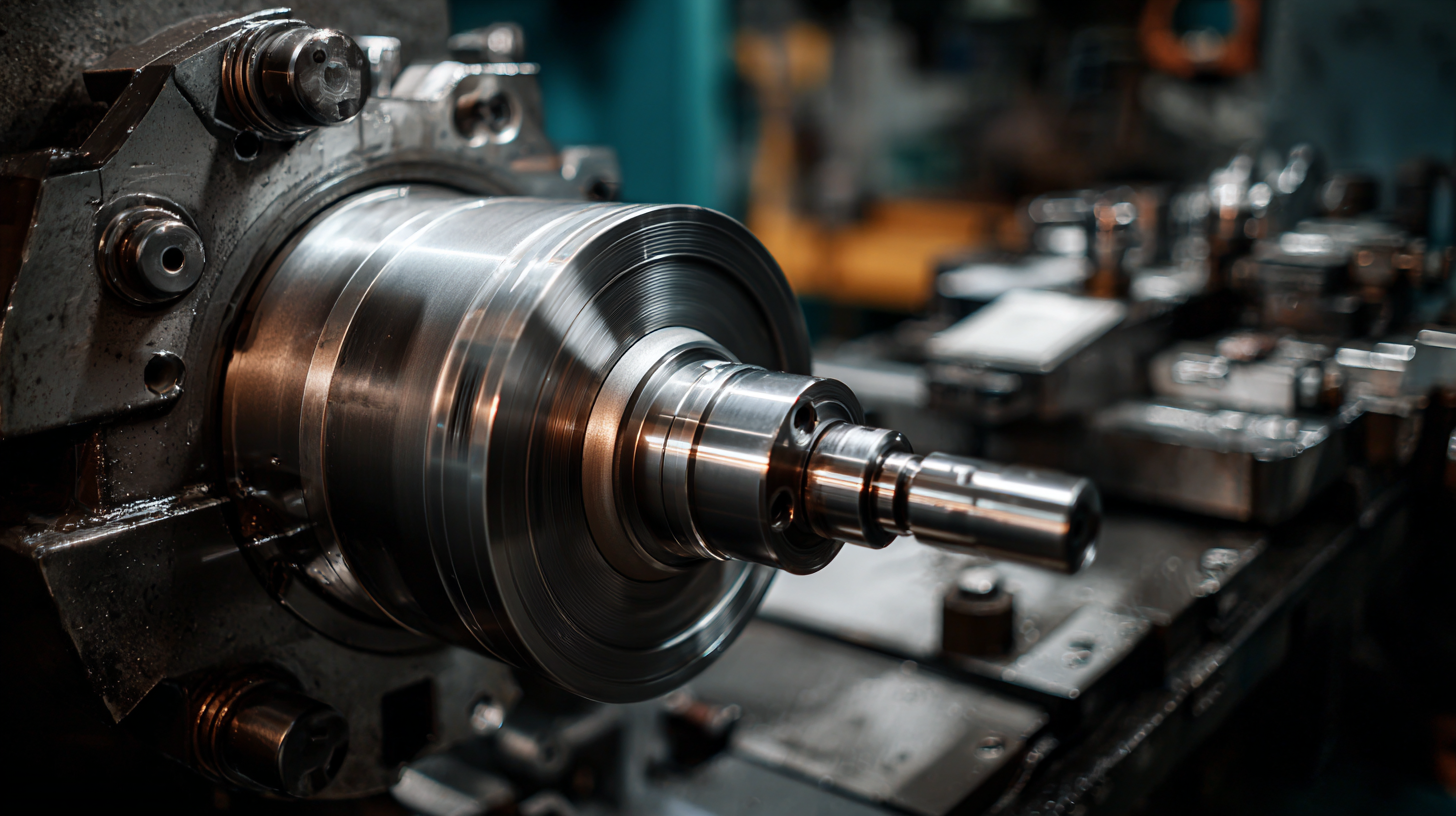

The role of lathe machine parts in precision engineering cannot be overstated, especially as the global CNC machine market is set to grow from $101.22 billion in 2025 to $195.59 billion by 2032, reflecting a compound annual growth rate (CAGR) of 9.9%. Each component—from spindles and tool holders to gear drives—plays a critical part in enhancing machine performance and precision, making it vital for manufacturers to invest in quality parts that ensure durability and accuracy in their operations.

Tips for maintaining optimal lathe performance include regular inspections and timely replacement of worn-out parts. For instance, ensuring that tool holders are aligned correctly can significantly affect machining precision. Additionally, using high-grade lubricants can reduce friction and wear on moving parts, ultimately extending the lifespan of the machine.

Moreover, embracing advanced technologies and automation in the lathe's operational framework not only enhances efficiency but also aligns with the precision engineering ethos. This shift not only fosters innovation within manufacturing but also contributes to productivity gains across various industries.

Key Features to Look For in Essential Lathe Machine Components

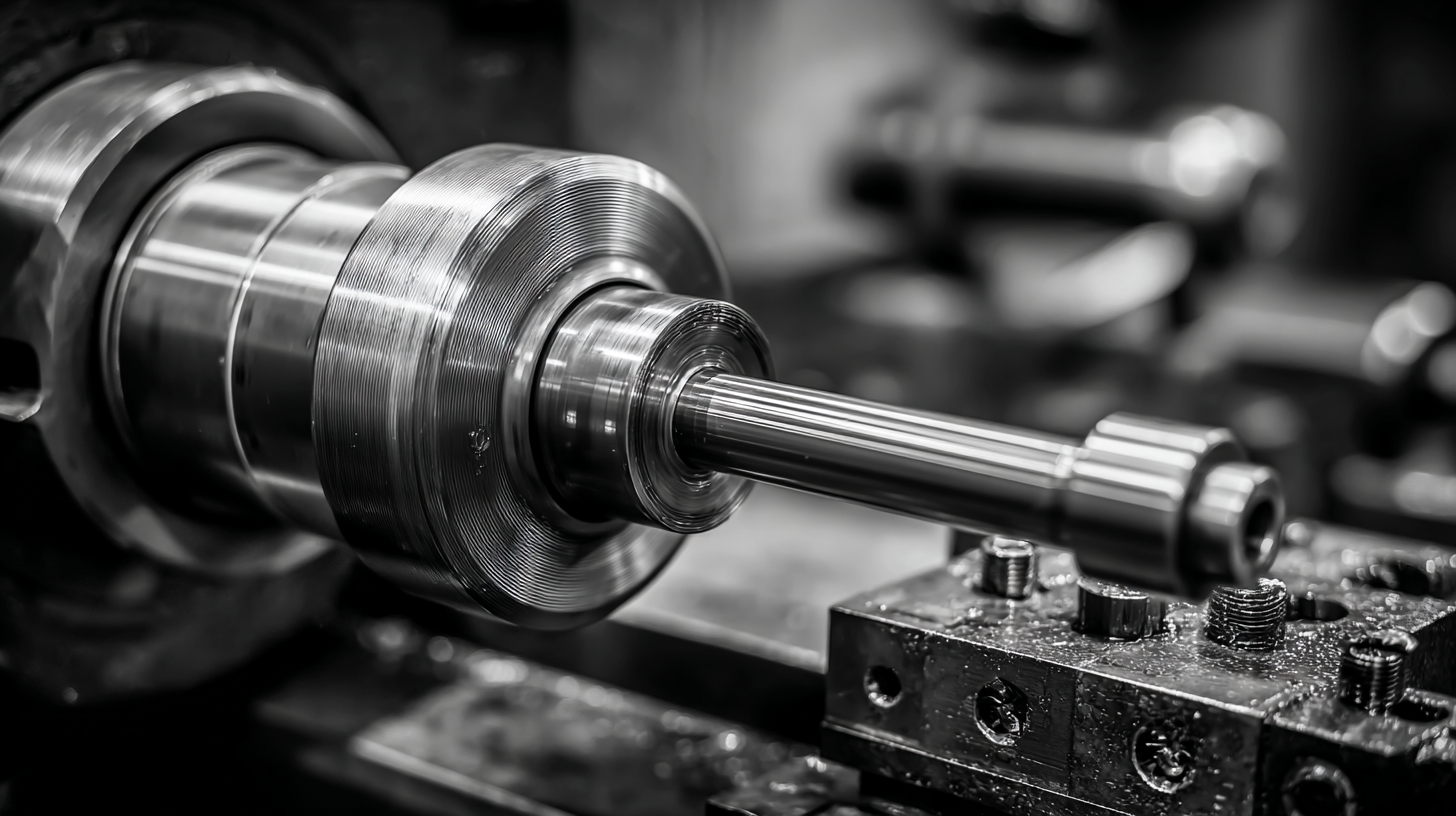

When considering the essential parts of a lathe machine for optimal performance, several key features should be prioritized. First and foremost, the spindle is crucial, as it dictates the rotational speed and stability of the workpiece. Look for spindles that offer variable speed options to suit various materials and projects, ensuring versatility in your machining processes. Additionally, a robust motor is vital for maintaining power and efficiency, particularly in high-precision jobs.

Another important component is the tool post, which securely holds the cutting tools in place. A high-quality tool post should allow for easy adjustments and provide stability during operation, facilitating accurate cuts. Furthermore, the bed of the lathe is significant for overall machine stability and alignment. A precision-engineered bed reduces vibrations and enhances the accuracy of machining operations, so choose a lathe with a heavy, well-designed bed structure.

These components collectively contribute to the lathe's performance, making them essential considerations for anyone looking to maximize their machining capabilities.

The Impact of Quality Components on Lathe Machine Performance

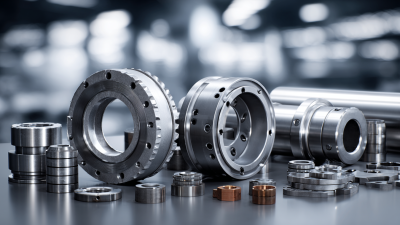

The performance of lathe machines is significantly influenced by the quality of their components. High-quality parts such as spindles, toolholders, carriage assembly, bed, and tailstock play crucial roles in ensuring precision and efficiency in machining operations. As the global CNC machine market is projected to grow from $101.22 billion in 2025 to $195.59 billion by 2032, the demand for reliable lathe machines that incorporate superior components is likely to rise correspondingly. Investing in top-tier components not only enhances productivity but also minimizes downtime and maintenance costs, thereby increasing overall machine lifespan and user satisfaction.

Moreover, advancements in technology, including the integration of artificial intelligence in CNC machining, further underscore the importance of quality parts. As industries pursue greater automation and precision, the need for durable and accurate lathe machine components becomes paramount. Businesses aiming to thrive in a competitive market must prioritize the selection of excellent components to optimize their lathe machines, ultimately leading to more efficient manufacturing processes and improved product quality.

2025 Top 5 Essential Lathe Machine Parts for Optimal Performance

This chart illustrates the importance of different lathe machine parts on overall performance, with quality components significantly affecting efficiency and precision.

Top Maintenance Tips for Longevity of Lathe Machine Parts

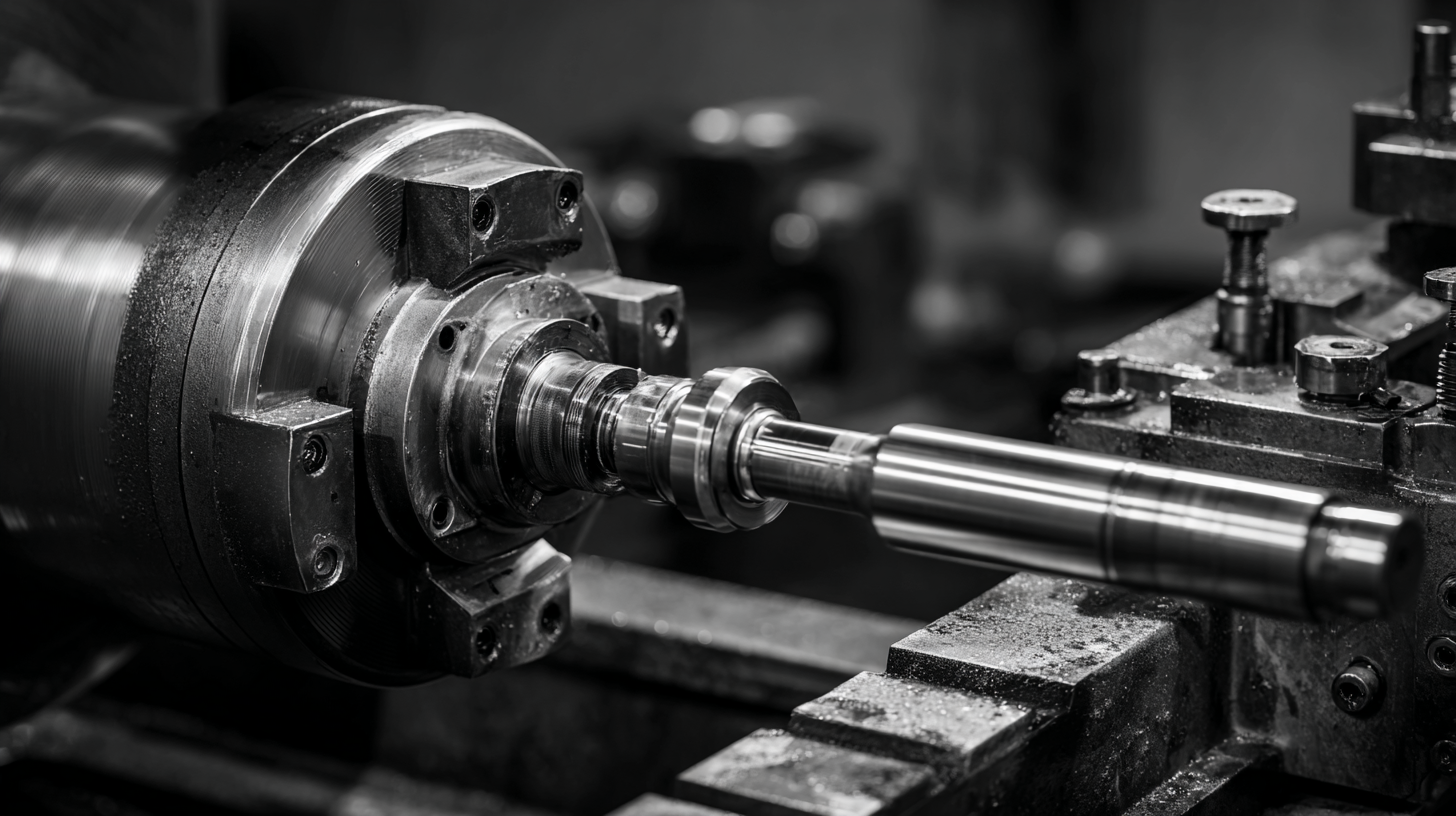

When it comes to maintaining the essential parts of a lathe machine, consistent care can significantly enhance their longevity and performance. Regular maintenance is crucial for optimizing the functionality of components like the spindle, chuck, tailstock, and tool holder. Keeping these parts clean and well-lubricated not only prevents wear and tear but also ensures smooth operations. In comparison, traditional machinery, like those still in use at Tinker Air Force Base, showcases the importance of maintaining older equipment—demonstrating that performance can be sustained with the right care.

Here are a few tips for maintaining lathe machine parts effectively: First, always clean the machine after each use to prevent dust and debris from accumulating. Second, regularly check the lubrication levels and apply a high-quality lubricant to minimize friction in moving parts. Finally, schedule routine inspections for parts like the bearings and belts to catch any signs of wear early, thereby preventing costly breakdowns in the future. Just as innovations in military equipment prioritize maintenance for longevity, your lathe machine can benefit greatly from these simple yet effective practices.

Innovations in Lathe Machine Parts to Enhance Operational Efficiency

The advancements in digital manufacturing technologies have ushered in a new era of innovation for lathe machine parts, greatly enhancing operational efficiency. As industries continue to evolve, the integration of smart technologies into lathe machines allows for real-time monitoring and data analysis, which leads to improved productivity and less downtime. This shift not only automates processes but also enables manufacturers to respond swiftly to changes in demand and customize products more effectively.

Tips for optimal performance include regularly updating software to ensure compatibility with the latest features, investing in high-quality cutting tools, and focusing on routine maintenance checks to prevent wear and tear. Furthermore, considering parts that allow for quick setup changes can drastically reduce production time.

Embracing these innovations is essential for staying competitive in the Europe CNC machine market, which is projected to grow significantly by 2033. As the market diversifies with a variety of lathe and milling machines, understanding the essential components that elevate performance is crucial for manufacturers looking to thrive in this dynamic landscape.

Related Posts

-

Discover the Best Techniques for CNC Turning Parts Manufacturing Efficiency

-

Unlocking Precision: How CNC Machining Parts are Revolutionizing Modern Manufacturing

-

Maximizing Efficiency and Precision in Manufacturing with CNC Lathe Technology Insights and Trends

-

Exploring the Future of Precision Engineering with CNC Turning Machines

-

The Future of Brass CNC Machining Innovations and Trends in Precision Engineering

-

Unlocking Innovation: The Vital Role of Machined Parts in Modern Manufacturing Advances