Top 10 Best CNC Machining Prototyping Services for Your Projects?

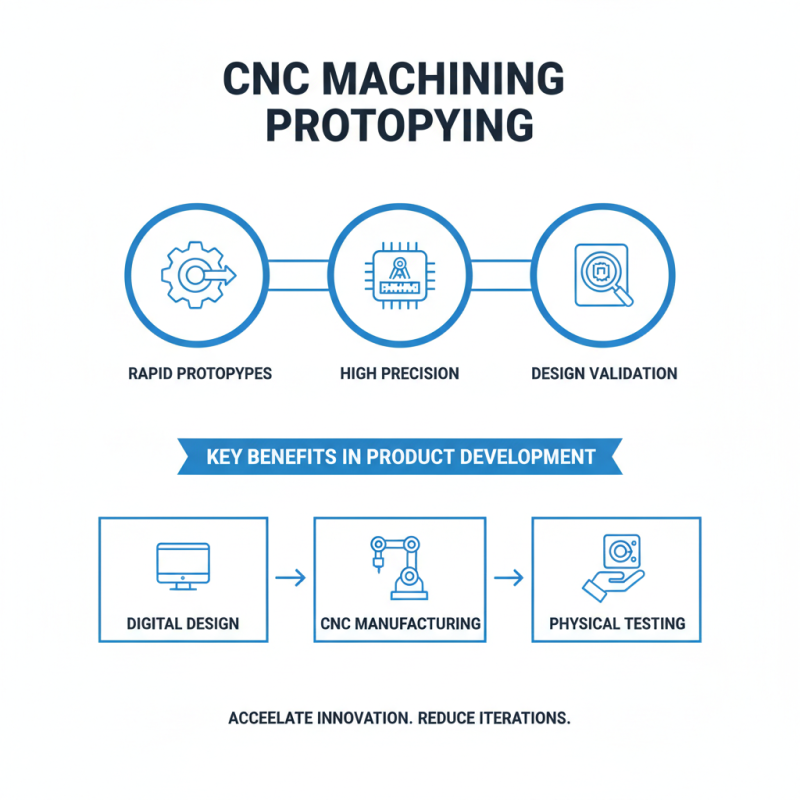

In today’s fast-paced manufacturing landscape, CNC machining prototyping is essential for bringing ideas to life. This innovative process allows engineers and designers to create high-precision prototypes quickly and efficiently. With the right service, you can streamline your project development and reduce costs.

The demand for CNC machining prototyping services has surged, pushing many providers to enhance their offerings. However, not all services guarantee quality and reliability. Some may fall short in meeting project deadlines or provide subpar materials. It’s vital to choose wisely, as the success of your project hinges on this choice.

Selecting the best CNC machining prototyping service requires careful consideration. Factors such as pricing, turnaround times, and expertise come into play. Occasionally, despite thorough research, you might encounter unexpected issues. These experiences highlight the importance of adaptability and learning from setbacks in the prototyping journey.

Overview of CNC Machining Prototyping Services

CNC machining prototyping services play a crucial role in product development. These services allow designers to create precise prototypes quickly. By utilizing computer numerical control technology, manufacturers achieve high accuracy. This precision is essential when testing new designs.

Many industries benefit from CNC machining. The automotive and aerospace sectors often rely on it for rapid prototyping. These prototypes help identify design flaws early in the development process. However, sometimes the prototypes do not meet initial expectations. This can lead to further revisions and delays.

Clients often find it challenging to navigate service options. Not all CNC machining providers offer the same quality or turnaround time. It requires careful evaluation to find the right fit. Inconsistent results can occur due to various factors. Material selection, machine calibration, and operator skill all play a role. Reflecting on these aspects can help in choosing the best service for specific needs.

Key Factors to Consider When Choosing a CNC Service

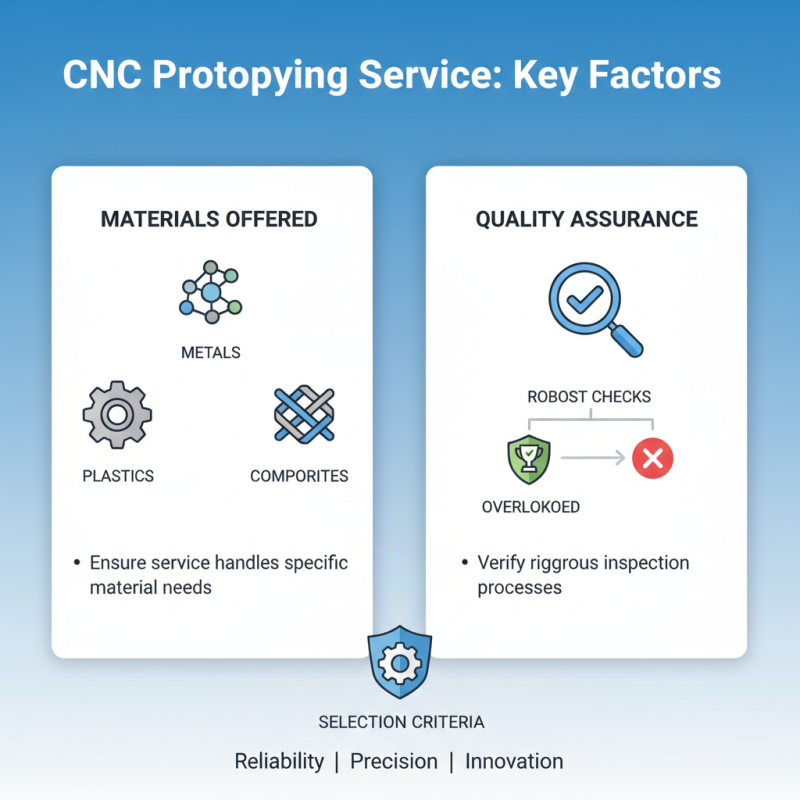

When selecting a CNC machining prototyping service, several key factors come into play. Consider the materials offered. Different services have varying capabilities in processing metals, plastics, and composites. It's crucial to ensure the service can handle your specific requirements. Quality assurance is another vital aspect. Some companies implement robust checks, while others may overlook this step.

Tips: Ask for samples. They often reveal a lot about a company’s capabilities. Understanding tolerances is equally important; each project has unique specifications that need precision.

Turnaround time is also significant. Some services boast quick deliveries, but speed shouldn't compromise quality. Ensure the service can meet your deadlines without cutting corners. Communication plays a critical role too. A responsive team fosters better collaboration, leading to smoother project execution.

Tips: Regular check-ins can clarify expectations. It’s also important to discuss post-production support. Sometimes, unexpected issues arise after prototyping. A reliable service will offer assistance when unforeseen challenges surface. Focus on these details to make the right choice.

Top CNC Machining Prototyping Companies Reviewed

Choosing the right CNC machining prototyping service is crucial for the success of your projects. With many options available, it’s vital to assess their capabilities carefully. Look for companies that offer a range of materials and finishes. This flexibility can significantly impact the quality and functionality of your prototypes.

When evaluating CNC machining firms, consider their experience and past projects. A solid portfolio often indicates reliability. Review customer feedback to gauge satisfaction levels. Trustworthiness can often be reflected in these testimonials. Pay attention to their ability to meet deadlines, as timing can be just as important as quality in a competitive market.

Tips: Always request samples of their work before committing. This will give you a tangible sense of their capability. Communication is key. Ensure the company listens to your needs and offers solutions tailored to your project. Be aware that pricing may vary widely, so budget wisely and look for value, not just the lowest cost. A low price can sometimes mean lower quality. Finding the perfect fit takes time and research, but it’s worth the effort for your project’s success.

Top 10 CNC Machining Prototyping Services Performance Comparison

Comparative Analysis of Pricing and Quality

When choosing CNC machining prototyping services, pricing and quality remain crucial factors. A recent industry report indicates that the average cost per hour for CNC machining can range from $50 to $150, depending on the complexity of the job. Projects that require intricate designs often push costs higher, with some providers charging up to 200% more for high-end materials or advanced techniques. These figures highlight the importance of understanding your project's demands before diving into a contract.

Quality metrics are equally essential. A study from a recognized manufacturing association revealed that up to 70% of customers prioritize precision in their prototypes. Many companies fail to meet these expectations, resulting in costly revisions. It is vital for clients to review a provider’s track record on precision and consistency. Not all services guarantee reliable performance, and some might compromise on quality to offer lower prices. Assessing previous client reviews and sample projects can provide clearer insights into the service's capability.

The balance between cost and quality is often delicate. Some providers may offer attractive rates but deliver subpar results. It forces clients to weigh the immediate savings against potential long-term issues. In this complex landscape, thorough research is essential for successful project outcomes.

Innovations in CNC Machining for Enhanced Prototyping

CNC machining has become a vital tool for prototyping. Innovations in this field are impacting production efficiency. According to a recent industry report, CNC technology can reduce prototype production time by up to 30%. This speed allows designers to iterate and refine their ideas faster than ever before.

Advancements such as multi-axis machining and automation are enhancing the capabilities of CNC machines. These improvements lead to more complex and precise prototypes. However, relying heavily on technology can lead to oversights. For instance, automated systems might miss minor design flaws that a human eye could catch. Engaging in consistent quality checks is essential to address this risk.

Data shows that companies investing in modern CNC technologies see a 20% increase in overall productivity. Yet, it’s crucial to find a balance. Dependency on automation can stifle creativity. Project teams must foster collaboration between machines and skilled operators to ensure innovative outcomes. Continuous improvement in CNC machining can redefine prototyping, but vigilance against potential drawbacks is key.

Related Posts

-

Discover the Best Techniques for CNC Turning Parts Manufacturing Efficiency

-

Unlocking Precision: How CNC Machining Parts are Revolutionizing Modern Manufacturing

-

Top Benefits of Fast CNC Machining for Your Manufacturing Needs

-

Top 10 Benefits of Fast CNC Machining for Your Manufacturing Needs

-

Ultimate Guide to CNC Turning Machine Benefits and Applications for Beginners

-

How to Choose the Best CNC Machining Prototyping Techniques for Your Project