Top 2025 CNC Mill Models: What to Consider for Precision Machining

In the ever-evolving landscape of precision machining, selecting the right CNC mill is paramount for achieving optimal results. As manufacturing processes grow increasingly complex, understanding the nuances of CNC mills becomes essential for companies striving for excellence. According to John Smith, an esteemed expert in the CNC milling industry, “The choice of CNC mill can make or break the efficiency and quality of production.” This statement underscores the importance of careful consideration when analyzing various models and their respective capabilities.

As we delve into the top CNC mill models of 2025, it’s crucial for industry professionals to weigh numerous factors that influence both performance and accuracy. From the machine's rigidity and power to the sophistication of its control systems, each element plays a significant role in facilitating precise machining. Furthermore, advancements in technology continue to reshape the functionalities of CNC mills, presenting manufacturers with groundbreaking options that enhance productivity and quality.

Understanding these developments not only aids in making informed decisions but also positions businesses to remain competitive in a rapidly changing market. This article will explore the key features and considerations that set apart the leading CNC mill models, offering insights for manufacturers who prioritize precision and efficiency in their machining processes.

Key Features to Consider in CNC Mill Models for Precision Machining

When selecting a CNC mill for precision machining, there are several key features to consider to ensure optimal performance and accuracy. First, the spindle speed and power are critical, as they directly impact the efficiency of machining operations. A higher spindle speed allows for faster cutting, while sufficient power ensures that the tool can handle tougher materials without compromising precision. This balance is essential for achieving smooth finishes and intricate designs.

Another vital aspect to evaluate is the machine's rigidity and stability. A rigid CNC mill minimizes vibration during operation, which in turn enhances the precision of the machined part. Consider models that feature robust construction and advanced vibration dampening systems. This stability not only improves accuracy but also extends the lifespan of both the machine and its tools.

Tips: Always review the machine’s specifications to ensure it meets the demands of your specific projects. Seek out models with adjustable parameters, allowing for flexibility in different machining tasks. Additionally, consider ease of maintenance, as regular upkeep plays a significant role in maintaining precision and prolonging the machine's operational lifespan.

Types of CNC Mills: Choosing the Right Style for Your Machining Needs

When selecting the right CNC mill for precision machining, it's essential to consider the various styles available and how they align with your specific machining needs. CNC mills can generally be categorized into three main types: vertical, horizontal, and multi-tasking. Each type serves different purposes and has unique advantages that can impact the efficiency and quality of machining projects.

Vertical CNC mills are renowned for their versatility and ease of use, making them ideal for a wide range of operations, from drilling to milling. Their upright design allows for efficient visibility of the workpiece, which contributes to precision when executing intricate designs. On the other hand, horizontal CNC mills are generally better suited for larger workpieces and can handle heavier loads, offering improved stability and cutting power. Their setup is optimal for operations that require multiple machining processes, reducing the need for tool changes and boosting productivity.

Multi-tasking CNC mills combine both turning and milling capabilities, making them a perfect solution for complex machining environments where time and precision are critical. These machines allow manufacturers to perform multiple operations in a single setup, greatly enhancing efficiency and reducing production times. In summary, understanding the strengths and ideal applications of each CNC mill style is vital for making an informed choice that meets the demands of precision machining.

Top CNC Mill Models for Precision Machining in 2025

Understanding CNC Mill Specifications and Their Impact on Performance

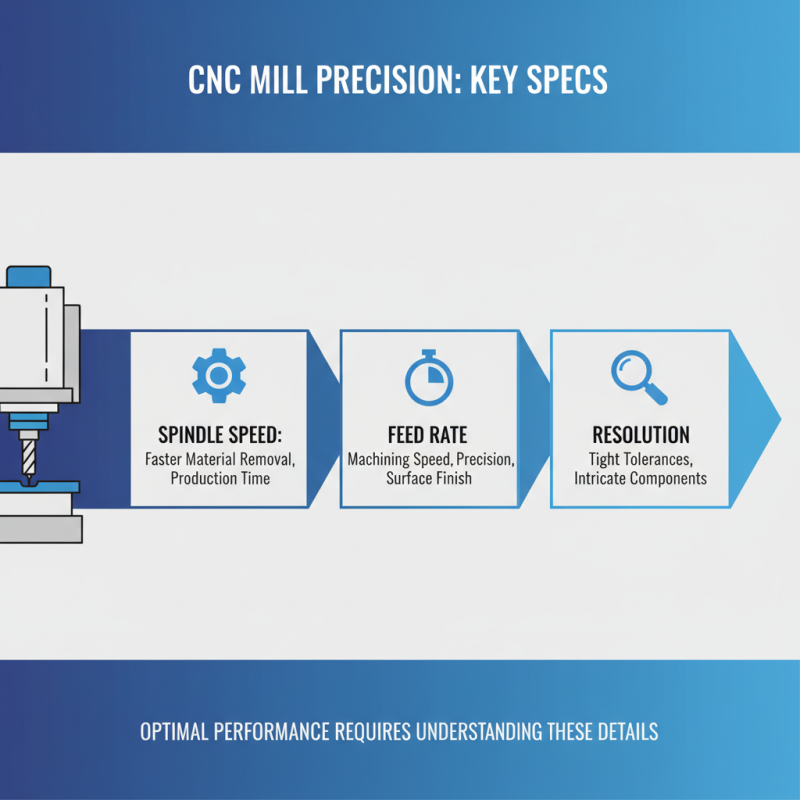

When choosing a CNC mill for precision machining, understanding the specifications is crucial for ensuring optimal performance. Key specifications such as spindle speed, feed rate, and resolution play a significant role in determining the capabilities of the machine. Higher spindle speeds can enhance material removal rates, allowing for faster production times while maintaining quality. Meanwhile, feed rates dictate how quickly the material is machined, which affects precision and surface finish. Attention to these details is essential for operators seeking to meet tight tolerances and produce intricate components.

Another critical specification to consider is the machine's rigidity and construction. A robust machine structure helps minimize vibrations during operation, contributing to improved accuracy and consistency in machining results. Additionally, the choice of control systems, such as open-loop versus closed-loop systems, impacts the responsiveness and precision of the milling operations. By evaluating these specifications, machinists can select a CNC mill that not only meets their production needs but also enhances overall machining performance and longevity.

Evaluating Software Compatibility for Enhanced CNC Mill Functionality

When selecting a CNC mill model for precision machining, evaluating software compatibility is a critical aspect that can significantly influence the machine's functionality. The software you choose determines how well your CNC mill will communicate with design files, enabling effective translation from digital designs to physical components. It is essential to ensure that the CNC mill's software supports popular design formats and integrates seamlessly with various CAD/CAM systems, which can enhance productivity and accuracy in machining operations.

Tips for ensuring software compatibility include checking the machine’s software specifications against your existing CAD/CAM systems. Look for mills that offer open architecture, allowing you to customize or upgrade to the latest software as your needs evolve. Additionally, choosing a CNC mill that provides robust tech support can be beneficial when dealing with software-related issues.

Another important consideration is the availability of updates and enhancements for the software. The machining landscape is constantly changing, and having access to regular updates can enhance not only the performance of your CNC mill but also keep it compatible with future technological advancements. Investing in a mill with a strong development community can also provide valuable insights and resources, further improving your machining capabilities.

Top 2025 CNC Mill Models: What to Consider for Precision Machining

| Model | Accuracy (μm) | Max RPM | Software Compatibility | Price Range ($) |

|---|---|---|---|---|

| Model A | 5 | 12000 | CAD/CAM, PLC | 5000 - 7000 |

| Model B | 3 | 15000 | SolidWorks, Fusion 360 | 7000 - 9000 |

| Model C | 7 | 10000 | MasterCAM, CATIA | 8000 - 12000 |

| Model D | 6 | 11000 | NX CAM, GibbsCAM | 6000 - 8000 |

| Model E | 4 | 13000 | Creo, Toad | 5500 - 7500 |

Budgeting for Your CNC Mill: Costs, Maintenance, and Long-Term Value

When budgeting for a CNC mill, understanding the initial purchase cost is just the beginning. The prices can vary significantly based on features, capabilities, and size of the machine. While opting for a lower-cost model may seem appealing, it’s essential to consider the long-term value of the investment. A more expensive CNC mill may offer advanced features and superior build quality, which can lead to better precision and fewer maintenance issues down the line—ultimately saving money over time.

Maintenance is another critical aspect of budgeting for a CNC mill. Regular upkeep is necessary to ensure longevity and optimal performance. Expenses can include routine maintenance checks, replacement parts, and potential upgrades. It’s important to factor these costs into your overall budget. Moreover, investing in training for operators and technicians can enhance productivity and reduce the likelihood of costly operational errors. By considering these ongoing costs, businesses can develop a comprehensive financial plan that aligns with their precision machining needs and capabilities.

Related Posts

-

Exploring the Future of Manufacturing: How CNC Machine Tools Revolutionize Precision Engineering

-

Discover the Best Techniques for CNC Turning Parts Manufacturing Efficiency

-

Unlocking Precision: How CNC Machining Parts are Revolutionizing Modern Manufacturing

-

Maximizing Efficiency and Precision in Manufacturing with CNC Lathe Technology Insights and Trends

-

2025 Top 10 CNC Machines: Unveiling the Future of Precision Engineering and Automation

-

Top 10 CNC Turning Parts Manufacturers for Precision Engineering Solutions