What is VMC Machine and How Does it Work?

The VMC machine, short for Vertical Machining Center, plays a crucial role in modern manufacturing. This advanced tool enables precision machining of various materials. It is essential for industries like aerospace, automotive, and electronics. The VMC machine uses computer numerical control (CNC) to automate the machining process.

The vertical design allows for efficient material removal. Tools can move in multiple axes, enhancing flexibility. Different types of tools can be used for milling, drilling, and tapping. This versatility makes the VMC machine indispensable in creating complex parts. However, operating a VMC machine requires skilled technicians. Mistakes can lead to errors in production.

Understanding how a VMC machine works helps in optimizing its use. Regular maintenance is vital to ensure its accuracy and longevity. Users should appreciate its capabilities while being aware of its limitations. Embracing this balance can lead to better manufacturing outcomes.

What is a VMC Machine?

A VMC machine, or Vertical Machining Center, is a vital tool in modern manufacturing. Its design includes a vertical spindle, which allows for precise vertical cutting. This setup is beneficial for creating intricate parts with tight tolerances. VMC machines often use various materials like metals, plastics, and composites. Their versatility makes them integral in industries such as aerospace, automotive, and medical device manufacturing.

The operation of a VMC machine involves several critical processes. It uses computer numerical control (CNC) software to program machine movements. The operator creates a digital model, translating it into machine instructions. While these machines offer high precision, errors can occur during programming. Sometimes, operators may face challenges in setting the right parameters. This aspect highlights the importance of training and experience.

Moreover, maintenance of VMC machines requires diligence. Regular checks on the spindle and tool wear are essential to ensuring efficient operation. Skipping these tasks can lead to unexpected downtimes. Operators must remain vigilant and continuously learn to improve their skills. Mistakes can occur, but reflecting on these experiences often leads to better practices in the future.

VMC Machine Performance Comparison

This bar chart represents the performance metrics of a Vertical Machining Center (VMC) machine, showcasing key parameters: Speed (RPM), Torque (Nm), Precision (µm), and Power (kW).

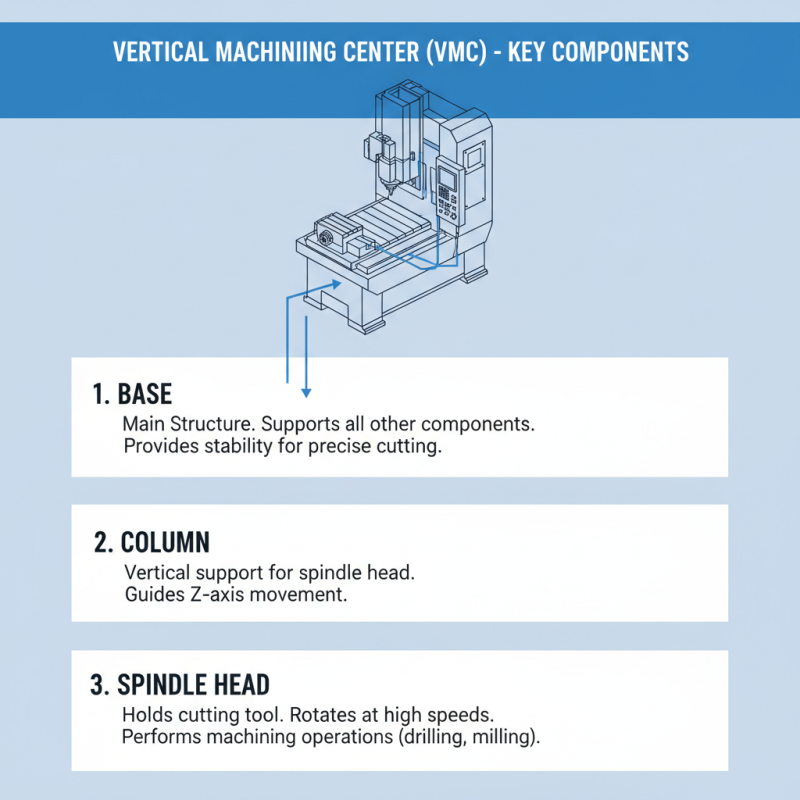

Key Components of a VMC Machine

A Vertical Machining Center (VMC) is a powerful tool used in modern manufacturing. Its key components play distinct roles in achieving precise machining. The main structure is the base, which supports all other components. It provides stability during cutting processes.

The spindle is another crucial component. This rotating tool holder drives the cutting tool, allowing for high-speed operations. Proper spindle speed is vital for different materials. The tool changer helps in automated processes, switching between tools efficiently. This feature allows for varied tasks without manual intervention.

Tips: Regular maintenance of the spindle is important. Check for vibrations and unusual sounds. A worn tool can affect quality. Ensure tools are sharp and suited for the task.

The control system manages the entire process. It interprets commands from the programmer, translating them into movements. An intuitive interface can improve workflow. Yet, some operators struggle with complex software. Familiarity with commands is key for better performance.

Tips: Attend training sessions for software updates. Understanding new features helps avoid costly mistakes. Always refer to the manual when unsure about operations.

How Does a VMC Machine Operate?

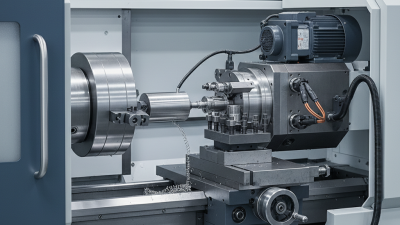

A Vertical Machining Center (VMC) is a powerful tool in modern manufacturing. It uses a rotating spindle to remove material from workpieces. The process is controlled by computer programming, ensuring precision. VMC machines often have multiple axes of movement. This allows for intricate designs and detailed cuts. Operators program the machine via CAD software, translating designs into code.

When a VMC operates, the workpiece is securely fastened on the table. The spindle then rotates at high speed, while the cutting tool moves along designated axes. This creates a smooth, uniform cut. The coolant helps manage heat and keeps the tool and workpiece in good condition. However, programming errors can lead to excess waste or damage. Operators must be mindful during the setup to avoid costly mistakes.

Maintaining a VMC is crucial for high performance. Regular checks on tools and software updates can prevent downtime. Even small deviations in programming can cause problems. It's imperative to have a keen eye for quality. A single flaw can ruin an entire batch of parts. Continuous learning and adaptation in using VMC is key for success in this field.

What is VMC Machine and How Does it Work?

| Feature | Description |

|---|---|

| What is VMC? | VMC stands for Vertical Machining Center, a type of CNC (Computer Numerical Control) machine tool that uses a vertically oriented spindle to perform various machining operations. |

| Working Principle | The VMC operates by moving a workpiece under a spindle that rotates and applies machining tools to shape the material through cutting. |

| Common Operations | Typical operations include milling, drilling, and tapping, allowing for high precision in the manufacturing process. |

| Uses | VMC machines are widely used in industries such as automotive, aerospace, electronics, and metalworking for creating complex parts and components. |

| Advantages | They offer high precision, reduced setup time, and the ability to perform multiple tasks in one setup, leading to improved efficiency. |

| Limitations | VMCs may have limitations regarding the size of workpieces and certain types of machining operations that require horizontal movement. |

Applications of VMC Machines in Manufacturing

VMC machines, or Vertical Machining Centers, have transformed manufacturing processes. They offer precision and efficiency in various applications. From automotive to aerospace, these machines streamline production. Their vertical orientation is key to maximizing tool accessibility. Operators can execute complex cuts with precision, creating intricate parts with ease.

In the automotive industry, VMC machines are used to produce engine components. These parts often require tight tolerances. A slight error can lead to significant performance issues. In aerospace, the stakes are even higher, with parts needing rigorous specifications. Manufacturers sometimes face challenges in maintaining consistency. Variability in machine operation can lead to imperfect components.

VMC machines also find value in the electronics sector. They help create intricate housings and circuit board elements. However, they can struggle with softer materials, leading to burrs. If not monitored closely, this can affect overall part quality. Continuous improvements are required to enhance performance and reduce waste. Addressing these imperfections ensures that VMCs remain a vital part of modern manufacturing.

Advantages of Using VMC Machines in Production

VMC, or Vertical Machining Center, has transformed modern manufacturing. These machines offer precision and efficiency, making them essential in high-production environments. The advantages of using VMC machines are numerous, but they shine mainly in speed and accuracy. According to a report by Techsci Research, the global VMC market is expected to grow at a CAGR of over 7% from 2021 to 2026.

One key advantage is reduced cycle time. VMCs can perform multiple operations in one setup. This not only enhances productivity but also minimizes human error. The accuracy level of VMC machines can reach up to ±0.005 mm. This high precision leads to fewer defects and less waste, ultimately saving costs in production.

Tips: Regular maintenance is crucial. Neglecting it can lead to decreased performance. Operators should monitor wear and tear closely. Training staff adequately also ensures machines run at peak efficiency. Continuous learning about VMC technology keeps you competitive. Emphasize innovation, but don’t overlook opportunities for improvement in your current setups.

Related Posts

-

Top Benefits of Using Machined Parts in Modern Manufacturing Processes

-

Top 10 CNC Turning Parts Manufacturers for Precision Engineering Solutions

-

Understanding the Importance of CNC Lathe Parts in Precision Machining

-

Top 10 CNC Milling Machines for Precision Machining in 2023

-

Exploring the Future of Precision Engineering with CNC Turning Machines

-

How to Choose the Right CNC Parts for Your Machining Projects